Finish rolling forming technique of numerical control ring rolling machine of internal long neck special-shaped wind power flange

A wind power flange and forming process technology, applied in the direction of metal rolling, can solve the problems of high raw material consumption, reduced forging performance, and low production efficiency, and achieve the effects of ensuring mechanical properties, improving efficiency, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

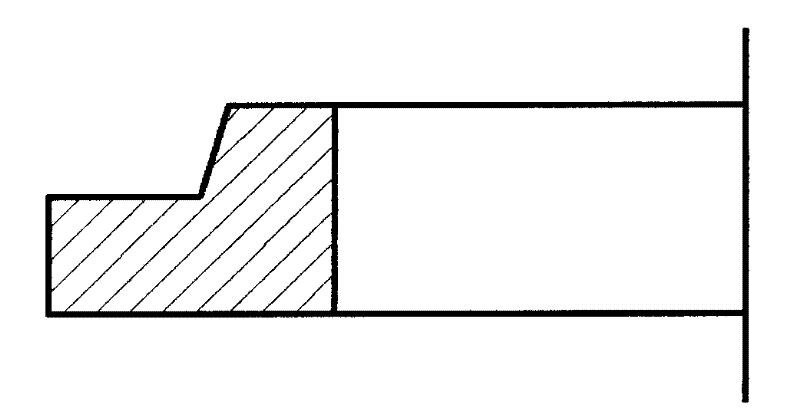

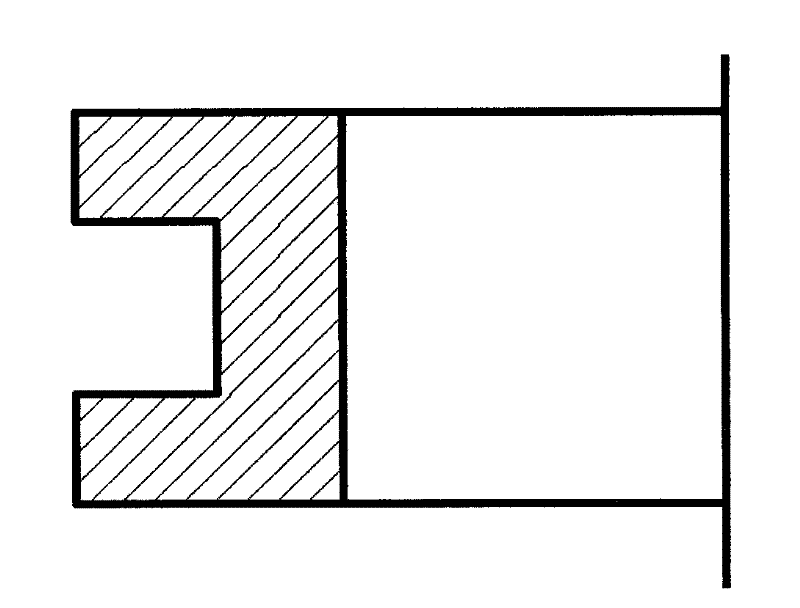

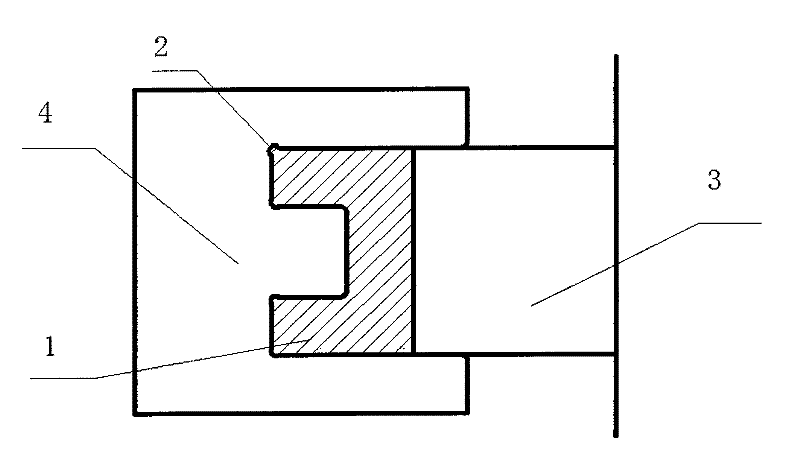

[0025] Such as figure 1 , figure 2 and image 3 As shown, a precision rolling forming process of an inner high-neck special-shaped wind power flange CNC ring rolling machine includes the following process steps:

[0026] Perform finite element forming analysis on it to determine the optimal size of the blank, and at the same time perform necessary optimization on the drive roll 4 pass and core roll 3, for example, the drive roll 4 pass contains grooves 2.

[0027] a) Select the continuous casting slab for blanking on the sawing machine.

[0028] b) After blanking, the heating furnace is heated according to the actual capacity of the heating furnace, and then the billet is made on the hydraulic press to make the billet; the initial forging temperature is controlled at 1180°C, the final forging temperature is 850°C, and the heating and holding temperature range is 1220°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com