Trans-scale micro-nano scale in situ tension compression mechanical property test platform

An in-situ stretching and testing platform technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as in-situ observation of high-resolution microscopic imaging systems, and achieve compact structure and strain Rate-controllable, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

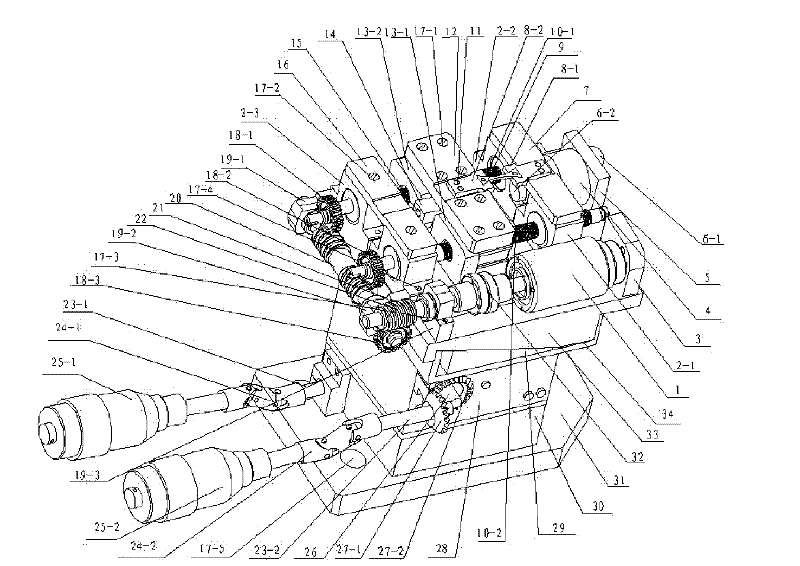

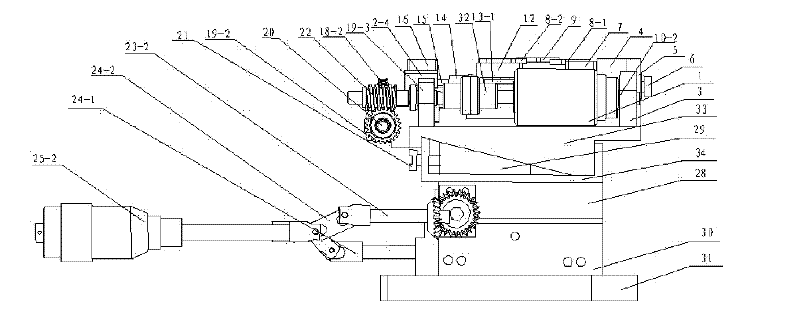

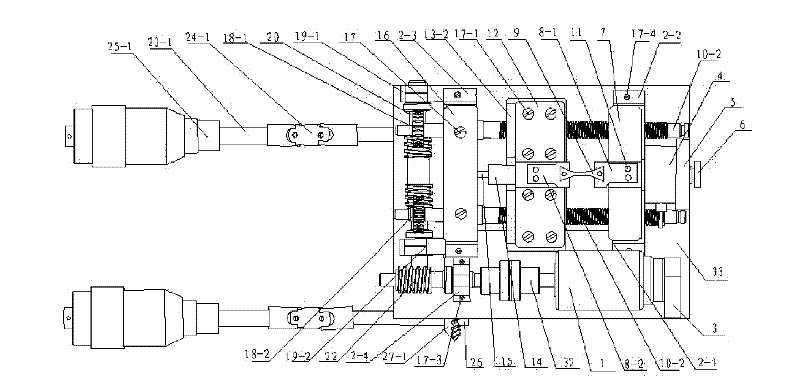

[0020] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the examples shown in the accompanying drawings.

[0021] See attached figure 1 , 2, 3, 4, a cross-scale micro-nano-scale in-situ tensile / compression mechanical performance testing platform according to the present invention, mainly consists of a precision drive unit, a signal detection control unit, a three-degree-of-freedom manual adjustment unit, clamping and support unit composition. The precision drive unit is connected by the DC servo motor 1 through the coupling 32 and the first-stage worm gear 18-3 worm 22, and is composed of the second-stage left and right worm wheels 18-1, 18-2, the second-stage worm 20 and the left and right precision ball screws. 10-1 and 10-2 decelerate and increase the distance of the rotational motion output by the DC servo motor 1 to provide a large tensile / compressive force and ultra-low strain speed, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com