Detection method for gamma-aminobutyric acid content in food by using high performance liquid chromatography method

A high-performance liquid chromatography and aminobutyric acid technology, which is applied in the field of high-performance liquid chromatography for detecting the content of γ-aminobutyric acid in food, can solve the problem of not formulating γ-aminobutyric acid and the like, and achieve reliable methods, The effect of reliable implementation and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

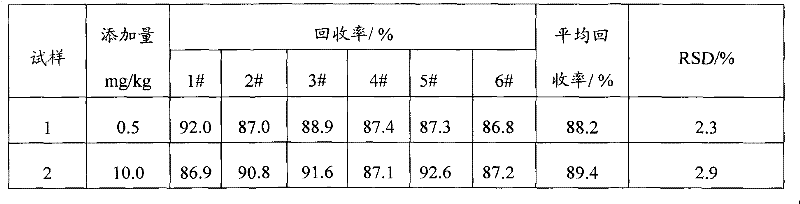

[0033] Example 1, detection of precision and recovery rate of gamma-aminobutyric acid content in food:

[0034] Prepare 0.4mol / L borate buffer solution (pH=10.2): Weigh 3.43g borax and 0.25g boric acid, add 80mL water to dissolve, adjust pH=10.20 with 5mol / L sodium hydroxide solution, and set volume to 100mL.

[0035] Preparation of derivative solution: Weigh 0.1g of o-phthalaldehyde, add 30μL of 2-mercaptoethanol, add 4.0mL of methanol, fully dissolve, and dilute to 5.0mL with borate buffer solution.

[0036] Weigh 2.0021g (accurate to 0.0001g) of the well-mixed sample to be tested, add pure water, make up to 10mL, vortex and mix thoroughly, ultrasonically extract for 2min, centrifuge at 3000r / min for 5.0min, pass through a 0.45μm filter membrane After filtration, it was derivatized and analyzed online by high performance liquid chromatography.

[0037] Weigh 100.00mg of γ-aminobutyric acid standard substance, dissolve it with secondary water and dilute it to a 100mL volumet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com