Self-fault tolerance magnetic flux switching permanent magnet motor

A permanent magnet motor and magnetic flux switching technology, which is applied in the direction of electronically commutated motor control, control generator, motor generator control, etc., can solve the problems of asymmetry of fault reverse potential and complementary damage, etc. Good independence, improved torque output performance, and simple armature winding structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

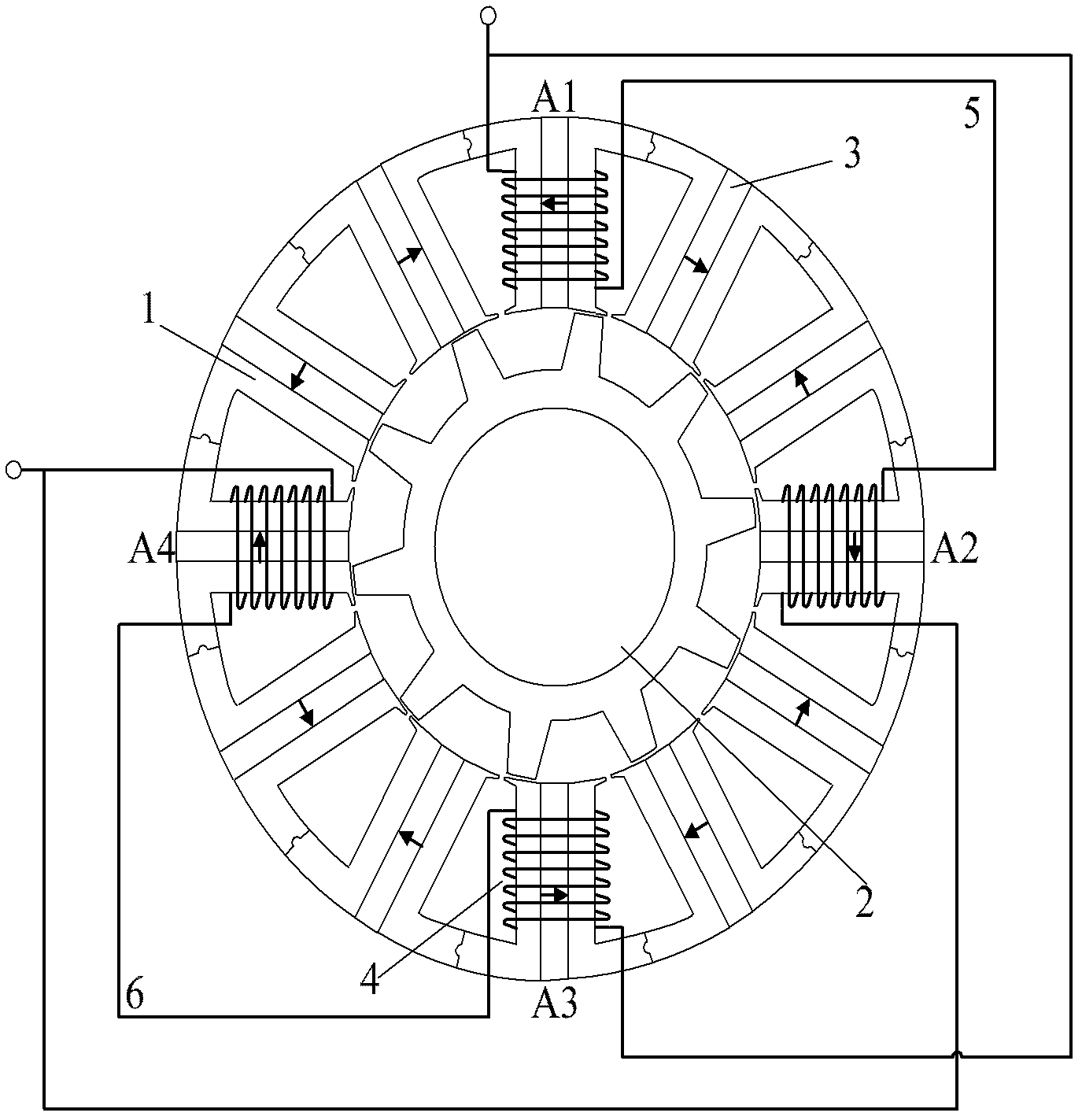

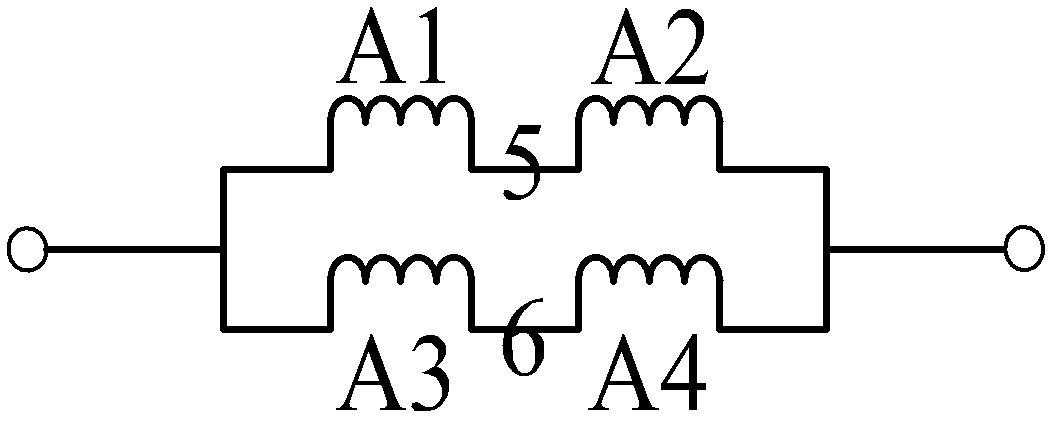

[0018] Taking a 12 / 10-pole self-fault-tolerant flux-switching permanent magnet motor as an example, its cross-sectional view is attached figure 1 shown. The self-fault-tolerant flux switching permanent magnet motor is composed of a stator 1, a rotor 2, a permanent magnet 3 and an armature winding 4; the stator 1 consists of 12 "U"-shaped stator cores and 12 "U"-shaped stator cores embedded in the middle The permanent magnets 3 are combined, and the permanent magnets 3 are distributed symmetrically to the center of the stator 1 . "U" shaped stator core and rotor core are pressed by silicon steel sheets figure 1 The shapes shown are stamped into stator core punches and rotor core punches respectively, and then a sufficient number of core punches and rotor core punches are stacked to form stator cores and rotor cores respectively. The armature winding 4 is a concentrated winding, and each coil winding straddles two teeth of the stator 1 . The 12 coils of the three-phase armatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com