Method for directly separating antimony and arsenic from flue dust containing antimony and arsenic

A kind of arsenic fume and direct technology, which is applied in the field of smelting special metal antimony and arsenic, can solve the problems of high cost, pollution of waste alkali slag, waste, etc., and achieve the effect of fast construction and production, low production investment and simple process smelting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

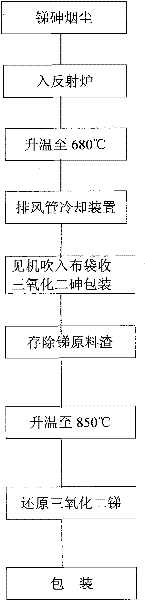

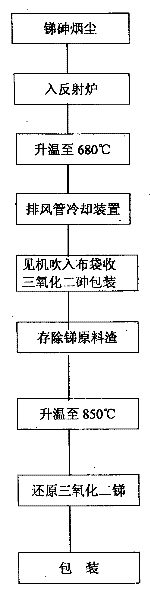

[0012] A. First, the antimony and arsenic fumes are evenly sent to the top of the reverberatory furnace according to the conventional technology pipeline conveying device and fall;

[0013] B. The above-mentioned antimony and arsenic fumes sent into the reverberatory furnace are heated to 680 ° C for combustion and refining;

[0014] C. Artificially stir and volatilize the raw materials in the above-mentioned combustion to generate arsenic trioxide vapor. Through the existing reverberatory furnace exhaust hole cooling device, the fan is blown into the baghouse to collect dust to obtain arsenic trioxide packaging. raw material slag;

[0015] D. Heat up the antimony raw material slag stored in the reverberatory furnace to 850°C for reduction again, and enter another baghouse to collect dust and antimony trioxide to be packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com