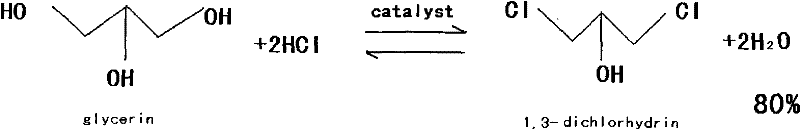

Method for synthesizing dichloropropanol by reaction of glycerol and hydrogen chloride

A technology of dichloropropanol and hydrogen chloride, which is applied in the fields of chemical industry and chemistry, can solve the problems of continuous unfavorable reactions, long reaction time, and reduction of catalyst content, and achieve the effects of shortening reaction time, improving selectivity, and avoiding consumption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

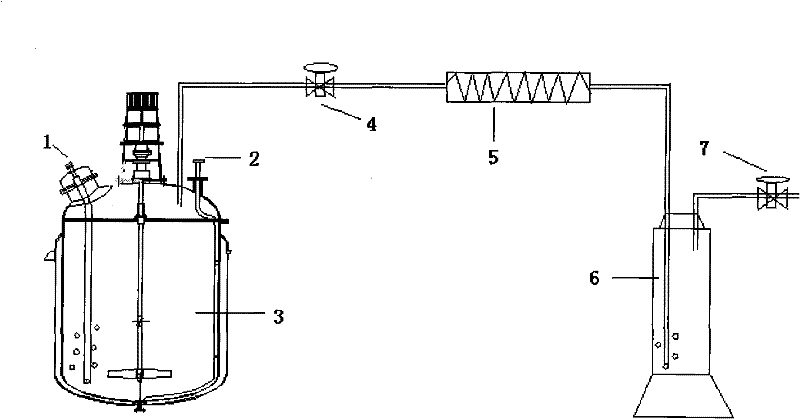

Method used

Image

Examples

Embodiment 1

[0023] Add 19.07g (207mmol) of glycerol and 1.184g (16mmol) of propionic acid to the reactor, heat it to 105°C, and feed 3.31mol of gaseous hydrogen chloride at a flow rate of 331mmol / h, the reaction time is 10 hours, sampling analysis, gas spectrogram results It shows that the conversion rate of glycerol is 99.3%, and the yield of dichloropropanol is 81.4%.

Embodiment 2

[0025] Add 19.07g (207mmol) of glycerin and 2.176g (16mmol) of zinc chloride to the reactor, heat it to 105°C, and feed 3.31mol of gaseous hydrogen chloride at a flow rate of 331mmol / h. The reaction time is 10 hours. Sampling test, gas spectrogram results It shows that the conversion rate of glycerol is 90.1%, and the yield of dichloropropanol is 77.8%.

Embodiment 3

[0027] Add 19.07g (207mmol) of glycerol and 1.49g (16mmol) of chloroacetic acid into the reactor, heat it to 105°C, and feed 3.31mol of gaseous hydrogen chloride at a flow rate of 331mmol / h. The reaction time is 10 hours. Sampling test is performed, and the gas spectrogram results show The conversion rate of glycerol was 70.2%, and the yield of dichloropropanol was 78.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com