Sintering plant operating simulation system

A technology for simulating operation and sintering plants, which is applied in the field of iron and steel smelting. It can solve problems such as dry running of equipment, unsafe equipment and on-site personnel, and repeated start and stop of equipment, so as to achieve the effects of no wear on equipment, saving production time, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] In view of this, the object of the present invention is to provide a sintering plant simulation operation system to enhance the safety and efficiency of sintering production.

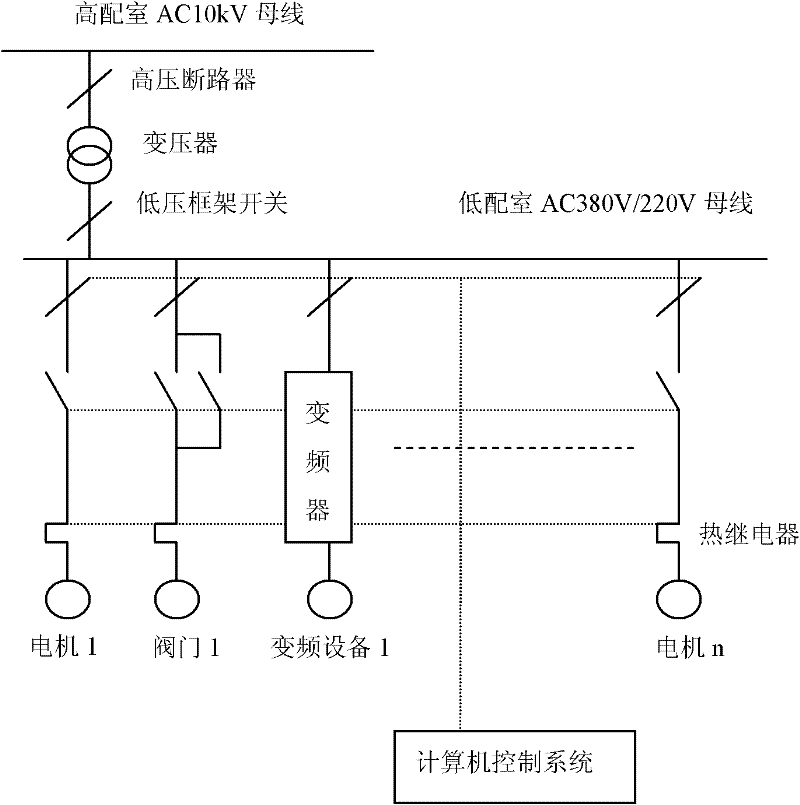

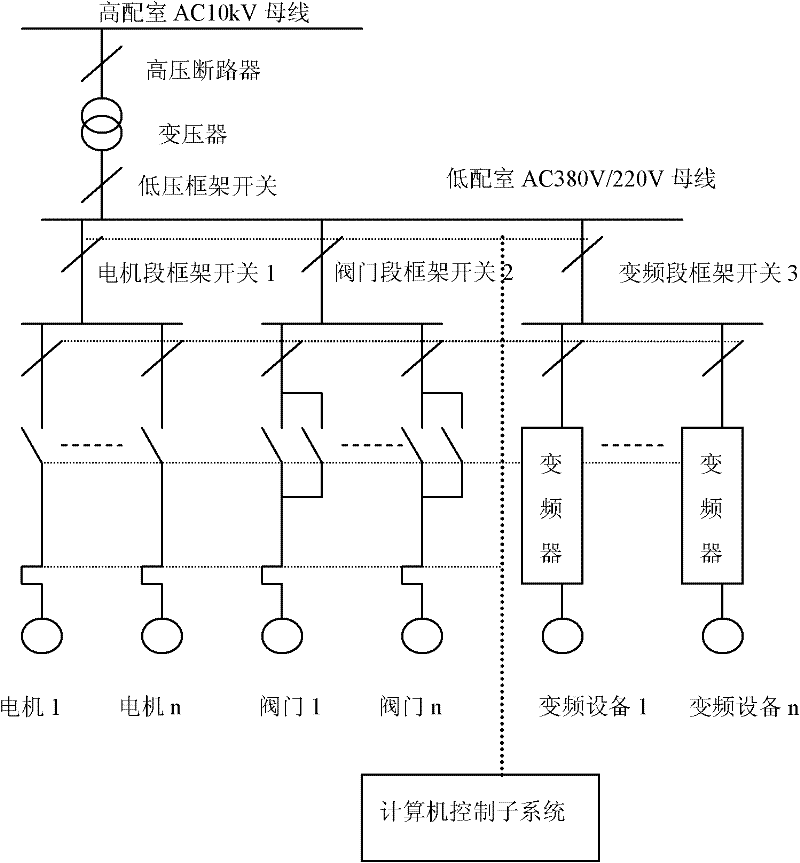

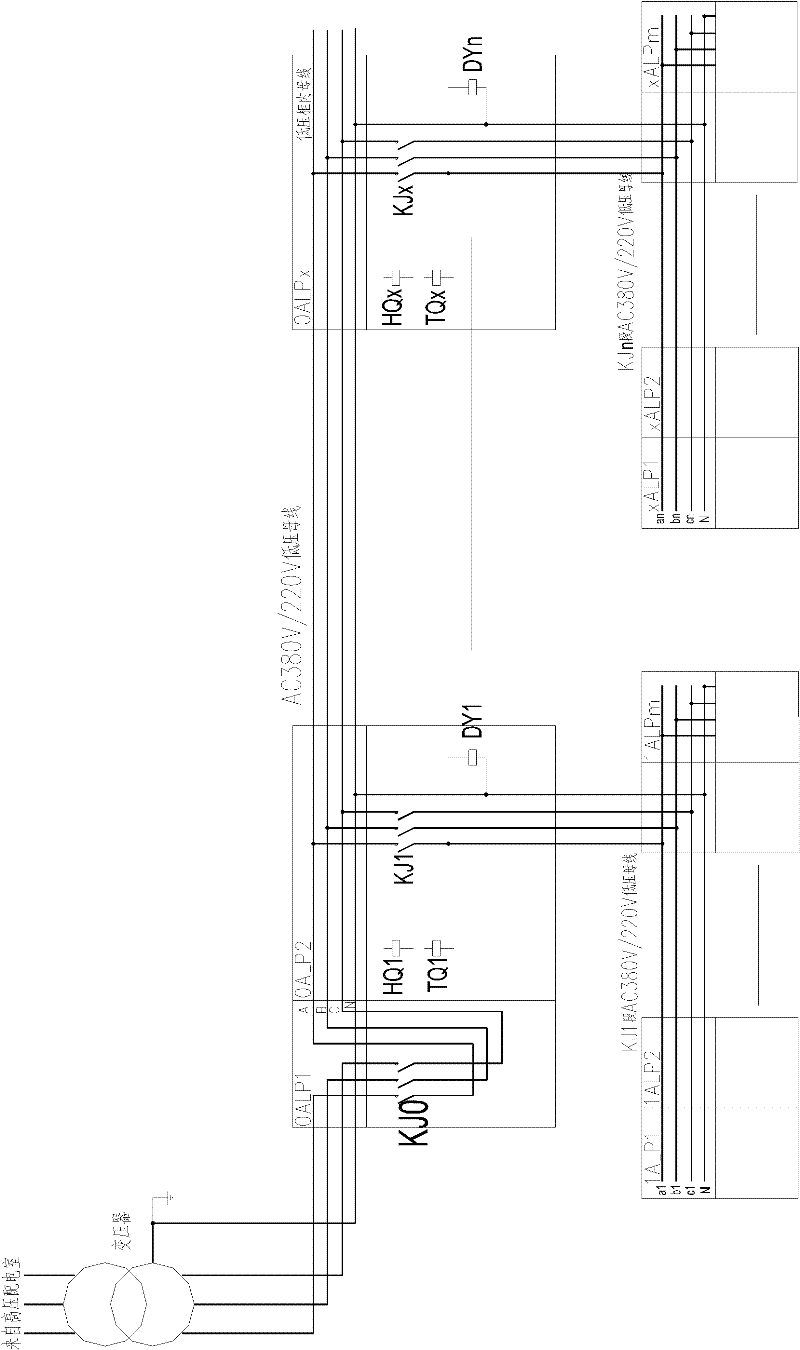

[0042] Aiming at the shortcomings of the existing sintering plant operation system, a sintering plant simulation operation system is established, so that in the simulated operation state, the main circuit of the sintering equipment does not receive power, and the control circuit of the equipment receives power independently. The simulation operation of the sintering equipment is carried out.

[0043] For the simulated operation system of the sintering plant, in the production preparation stage, the simulated start-up operation is first carried out. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com