Permanent magnet powerless magnetic brake

An electromagnetic brake and permanent magnet technology, which is applied in the direction of brake types, brake components, brake actuators, etc., can solve the problems of inability to achieve clamping, high processing costs of parts, and prone to fatigue fractures, etc., to achieve processing and assembly Low cost, reduced production cost, and the effect of completely releasing the brake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

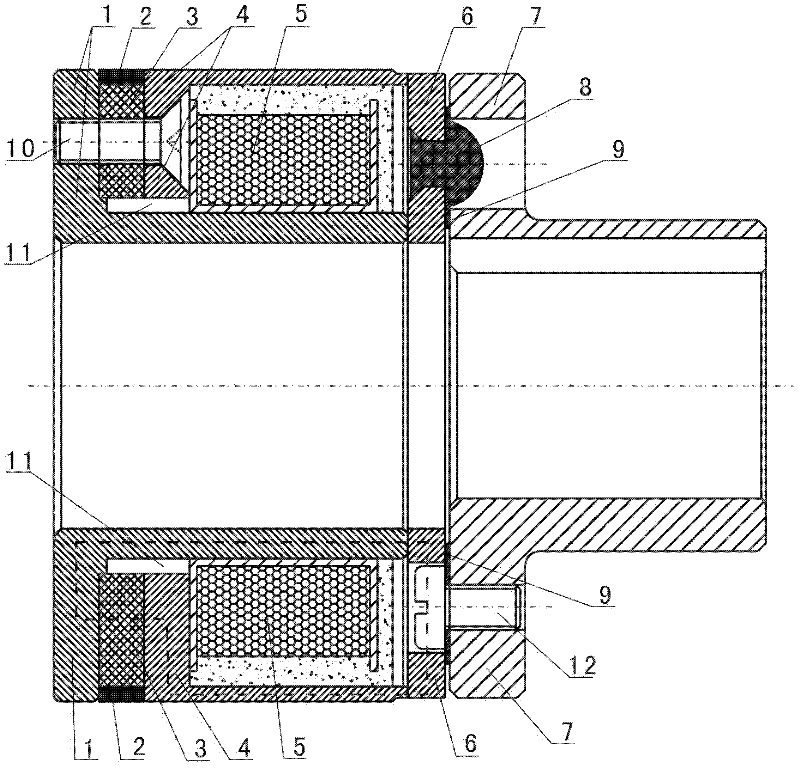

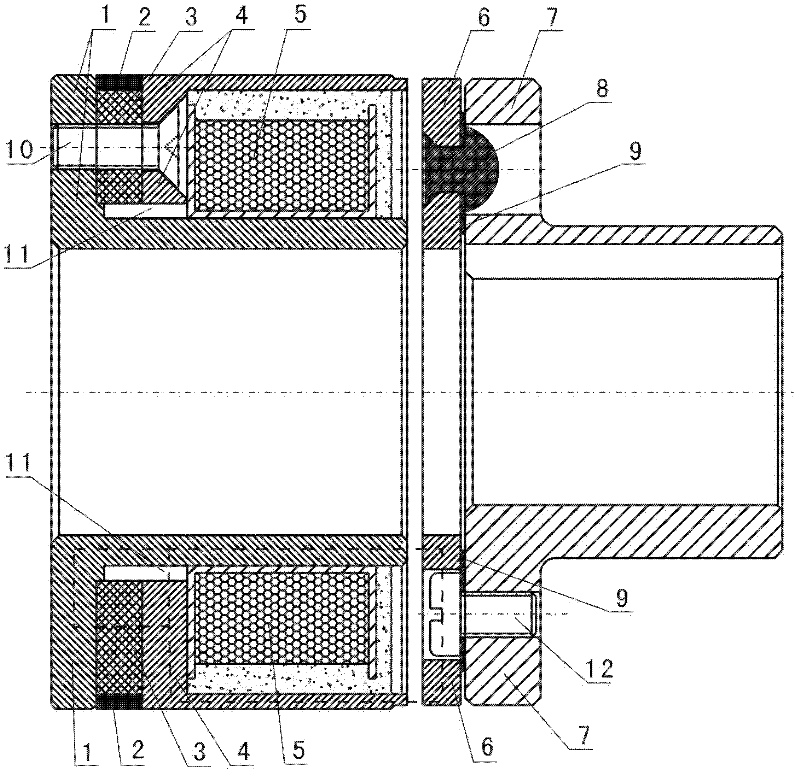

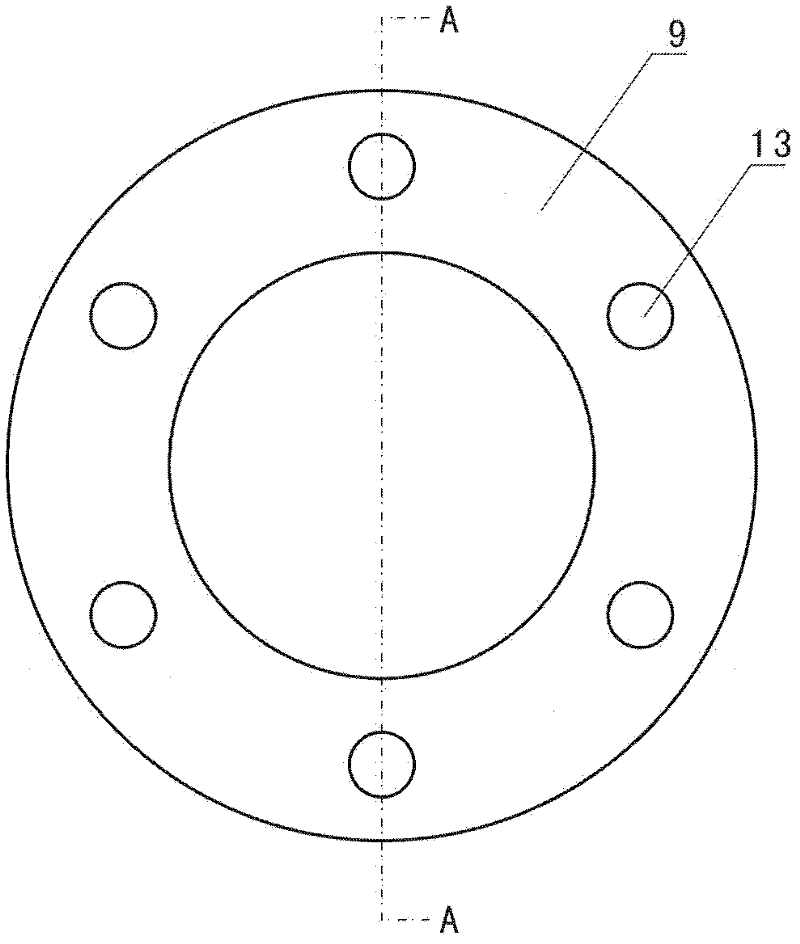

[0031] Such as figure 1 As shown, the present invention includes a stator assembly and a rotor assembly, and the structure of the stator assembly is: a coil assembly 5, an inner yoke 1, an outer yoke 4 and a permanent magnet 3, one end of the inner yoke 1 and the permanent magnet 3 One magnetic pole (N pole or S pole) is fixedly connected, the other magnetic pole (S pole or N pole) of the permanent magnet 3 is fixedly connected with one end of the outer yoke 4, and cross recessed countersunk screws 10 pass through the outer yoke respectively 4. The permanent magnet 3 and the inner yoke 1 are fixed, and the coil assembly 5 is installed in the gap between the inner yoke 1 and the outer yoke 4, and epoxy resin is potted around the coil assembly 5 to fix it; the rotor assembly The structure is: including the flange 7, the surface spring 9 and the armature 6, the flange 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com