Non-contact temperature measurement electromagnetic oven and temperature measuring method

A non-contact, electromagnetic cooker technology, applied in the direction of thermometers using directly heat-sensitive electric/magnetic elements, using electromagnetic means, thermometers, etc., can solve the problems of control principle description, and the prior art does not give any enlightenment, etc., To achieve the effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] In this embodiment, the temperature measurement process of an electromagnetic oven is used to illustrate the non-contact temperature measurement method of the present invention. See attached Figure 10 , 11 .

[0077] The induction cooker described in this embodiment includes: an induction cooker shell 2, an induction cooker platen 3, a heating coil 4 and a control circuit, wherein the control circuit includes a control board 1 and a driving board 8, and the center of the heating coil 4 is provided with a support frame 5 , the support frame 5 is equipped with a thermistor 7 .

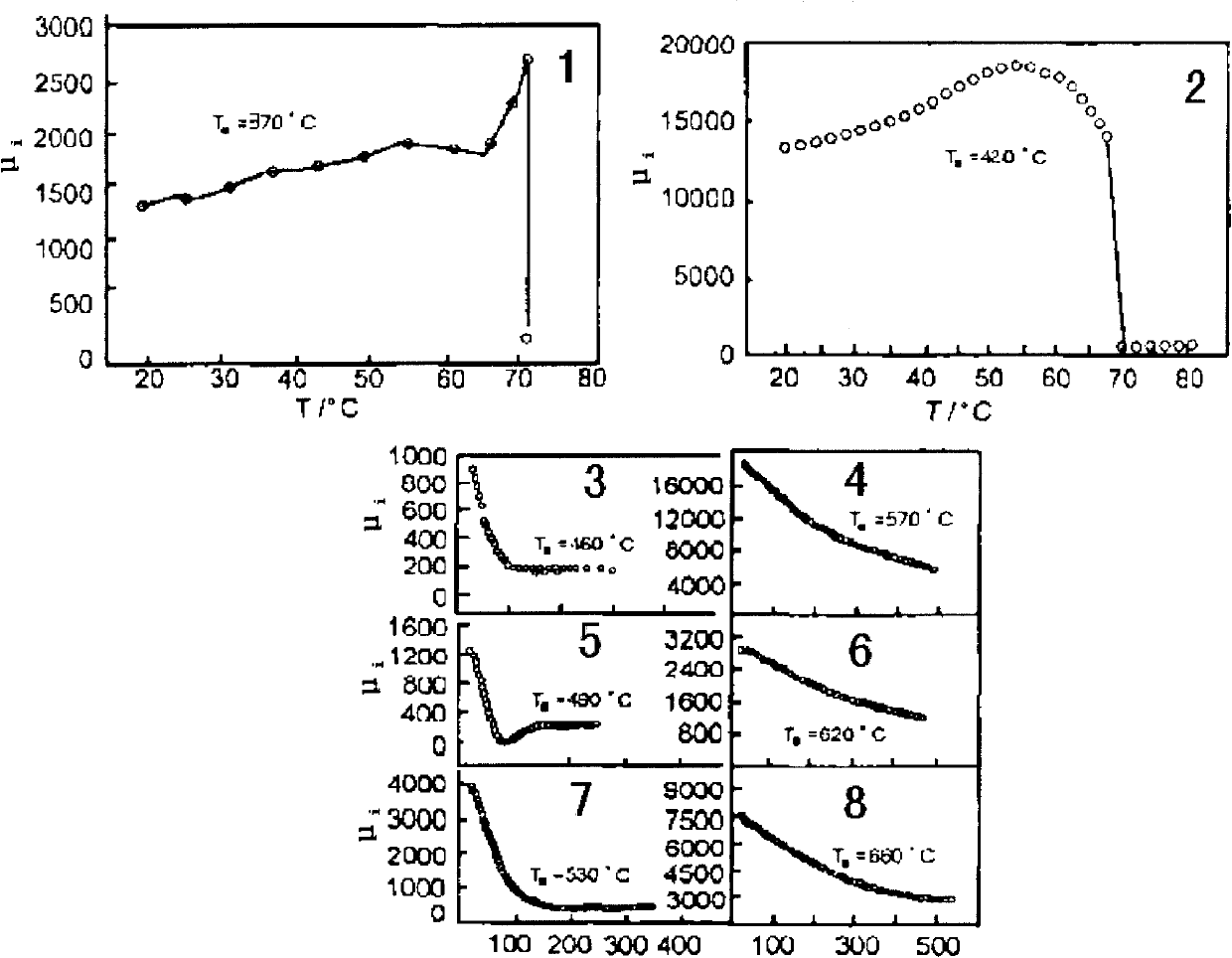

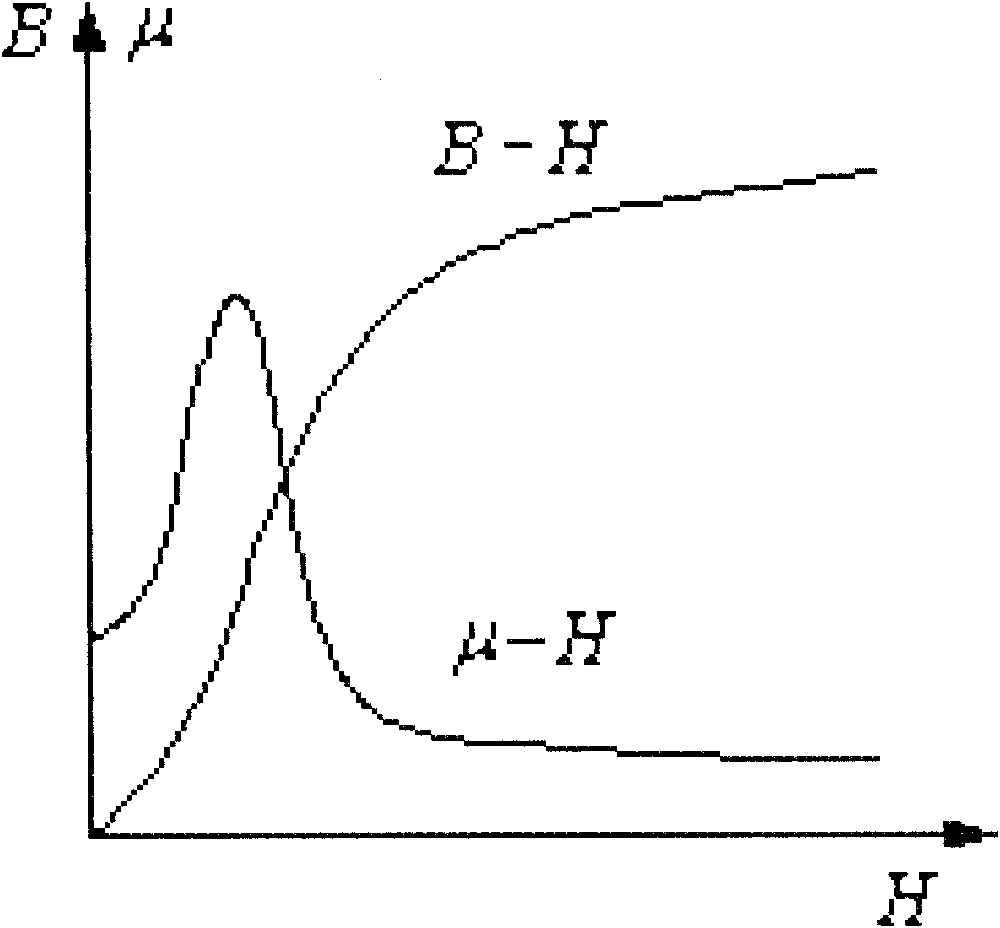

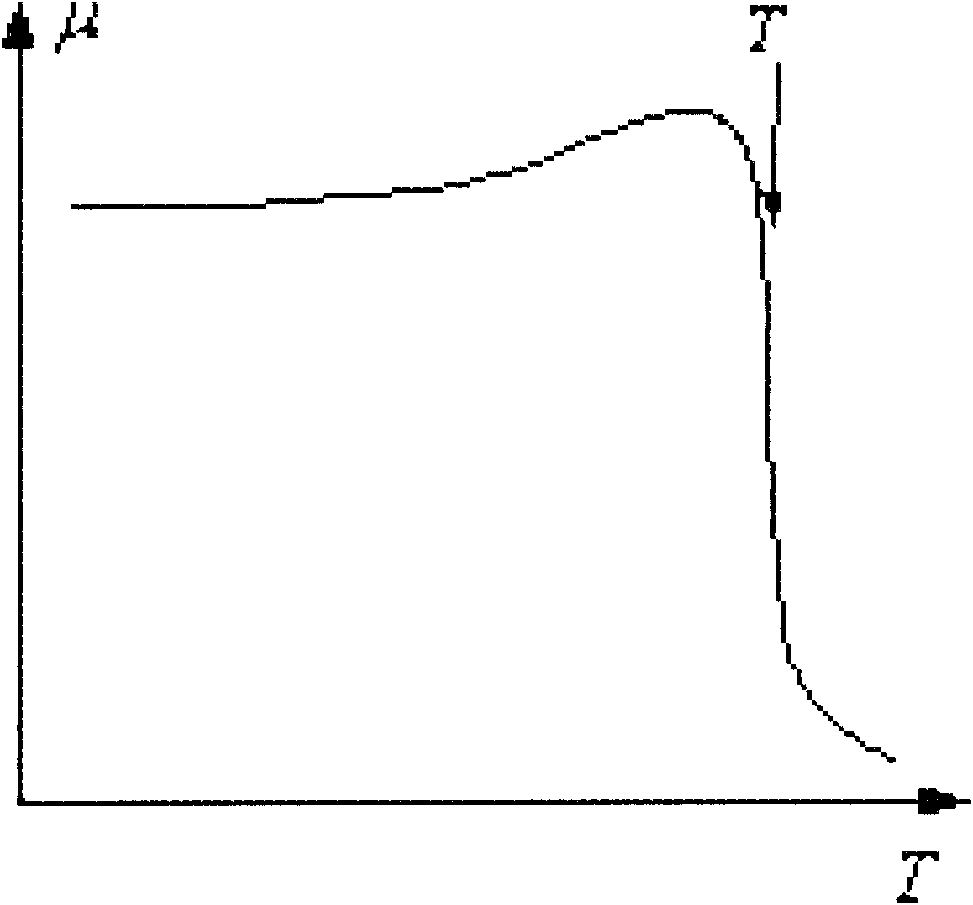

[0078] A temperature-measuring induction coil 6 is also provided below the induction cooker platen 3, and the magnetic temperature-sensing element 10 is fixed together with the cooking heating pot 9, and the magnetic field change generated at a corresponding temperature point is converted into an electrical signal and output, and the temperature-measuring induction coil 6 is matched with the h...

Embodiment 2

[0086] In this embodiment, other is the same as Embodiment 1, the difference is that the magnetic temperature sensing element 10 is embedded in the position where the table top is in contact with the cooking heating pot 9, and the temperature-measuring induction coil and its substantially opposite place are placed under the table, An exciting coil is set independently, and the temperature is measured regularly when the heating coil is cut off. The temperature-measuring induction coil and the excitation coil are fixed below the induction cooker platen together by the support 5a, corresponding to the position of the magnetic temperature-sensing element, the support 5a is a plate frame whose longitudinal section is stepped, and the temperature-measuring induction coil and the excitation coil are the same The shaft is fixed on the board frame.

Embodiment 3

[0088] Others are the same as in Embodiment 1, the difference is that the temperature measuring induction coil 6 described in this embodiment adopts a Hall element. Specifically, this embodiment adopts a Hall element prepared by utilizing the Hall effect as the present embodiment. The temperature-measuring induction coil of the non-contact temperature-measuring method described in the invention is specifically: a rectangular sheet made of a uniform N-type semiconductor material, the sheet has a certain length, width, and thickness, and two sides in the length direction A voltage is applied to the terminal, and the position of the Hall element is within the effective range of the magnetic field of the magnetic temperature sensing element 10 .

[0089] When the magnetic temperature sensing element 10 causes the magnetic field B to change under the change of temperature, the change of the magnetic field B substantially perpendicular to the wide surface of the Hall element causes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com