Cone-shaped reverse diversion furnace gas circulation device

A circulation device and reverse technology, applied in the field of furnace gas circulation device structure, can solve problems such as uneven furnace temperature and atmosphere, reduced convective heat transfer capacity, and prolonged heating time, so as to improve hot air circulation efficiency, reduce resistance, and improve performance Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

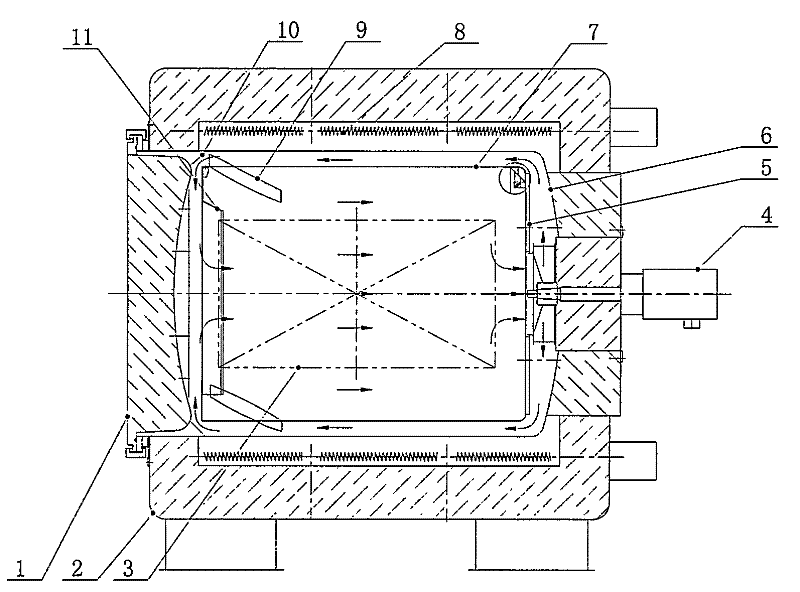

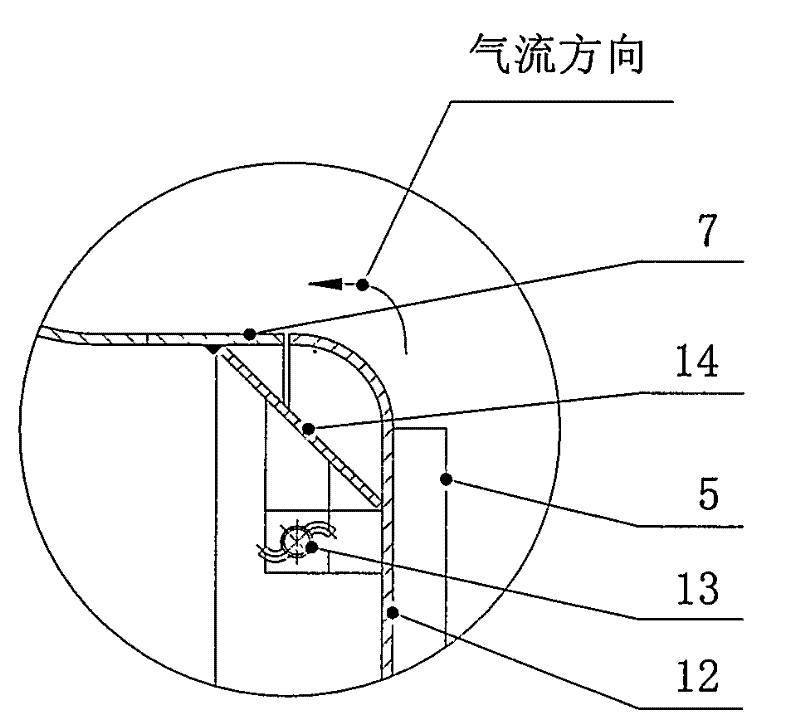

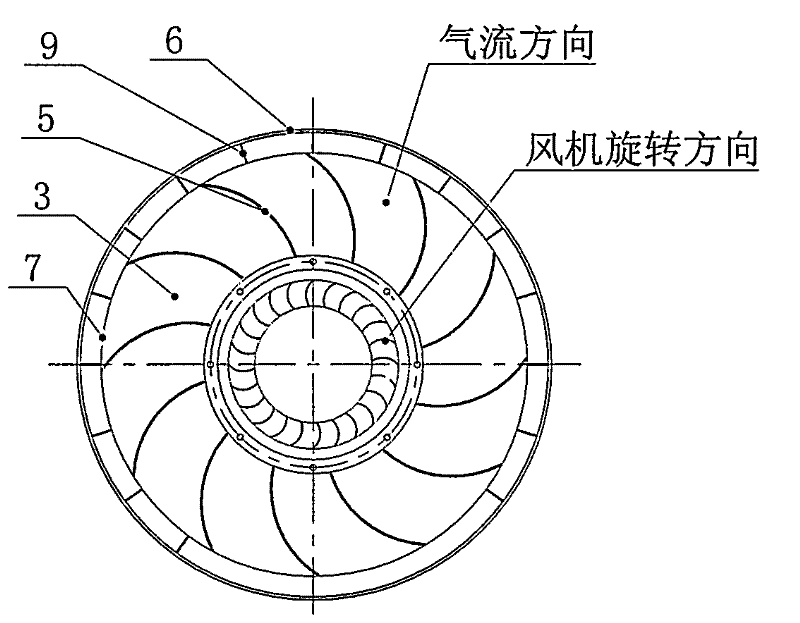

[0010] Such as Figure 1 ~ Figure 3 As shown, this embodiment includes: 1. furnace door, 2. shell, 3. workpiece, 4. circulating fan, 5. rear end reverse deflector, 6. furnace tank, 7. air guide tube, 8. heating Components, 9, front end reverse deflector 10, front conical deflector, 11, air flow baffle, 12, air guide plate, 13, bearing pin, 14, rear end conical deflector. The connection method is: the air guide tube (7) is installed in the furnace tank (6), one end of the rear conical guide plate (14) is welded on the inner side of the end of the guide tube (7), and the air guide plate (12) It is connected with the rear conical deflector (14) through the pin shaft (13), the rear reverse deflector (5) is welded on the wind deflector (12), and the rear reverse deflector (5) is installed The rear spiral direction is opposite to the rotation direction of the circulation fan (4), the circulation fan (4) is installed on the fan mounting seat of the furnace tank (6), and the front re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com