Spiral optical fiber sensing device based on bending deformation of optical fiber

An optical fiber sensing, helical technology, applied in the direction of using optical devices, using optical devices to transmit sensing components, measuring devices, etc., can solve the uniformity of internal density and fine machining defects, limit sensor accuracy, and expand the scope of use and other problems, to achieve the effect of flexible use, convenient operation, and convenient processing and production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

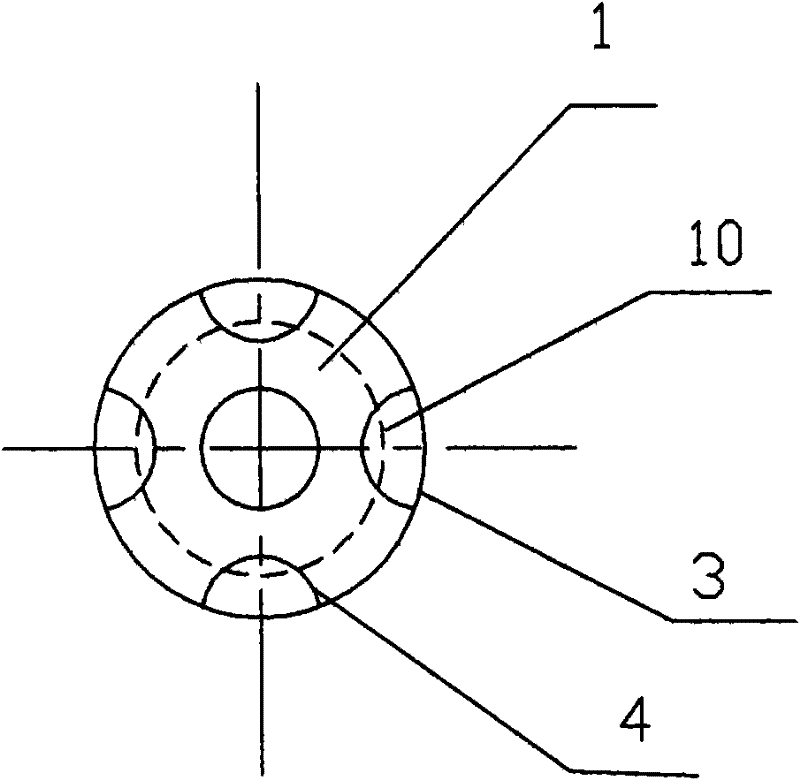

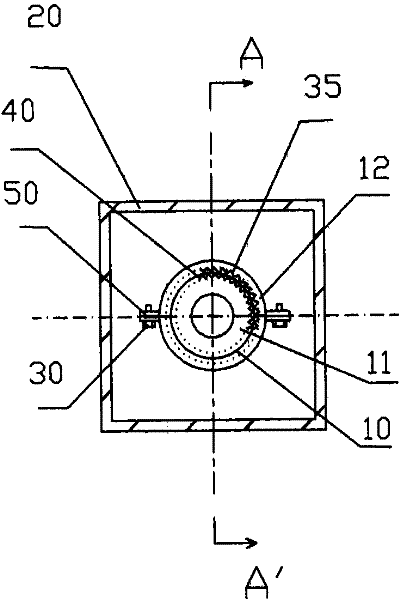

[0038] Such as image 3 , Figure 4As shown, the present invention includes an inner cylindrical body 11 and a housing 12 outside the inner cylindrical body 11 in an outer cavity 20, and a plurality of inner cylindrical outer surface grooves 40 are longitudinally distributed on the surface of the inner cylindrical body 11, On the inner surface of the housing 12 outside the inner cylindrical body 11, there are also a plurality of housing inner surface grooves 35 distributed along the longitudinal direction, and the outer surface grooves 40 of the inner cylindrical body are connected with the inner surface of the outer housing 12 of the inner cylindrical body 11. The grooves 35 on the inner surface of the housing are staggered, and there is a thread 60 on the surface of the inner cylindrical body 11. The signal optical fiber 10 is wound in the valley of the thread 60, and the signal optical fiber 10 is clamped by the groove 40 on the outer surface of the inner cylindrical body. ...

Embodiment 2

[0046] Such as Figure 5 As shown, in this embodiment, the difference from Embodiment 1 is that: one end of the signal fiber 10 is provided with a light reflection device, the other end of the signal fiber 10 is connected to the extension fiber 80, and the extension fiber 80 is connected to the 1X2 splitter 21 1 port, 2 ports of the 1X2 splitter 21 are respectively connected to the optical input and output ports of the test unit. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

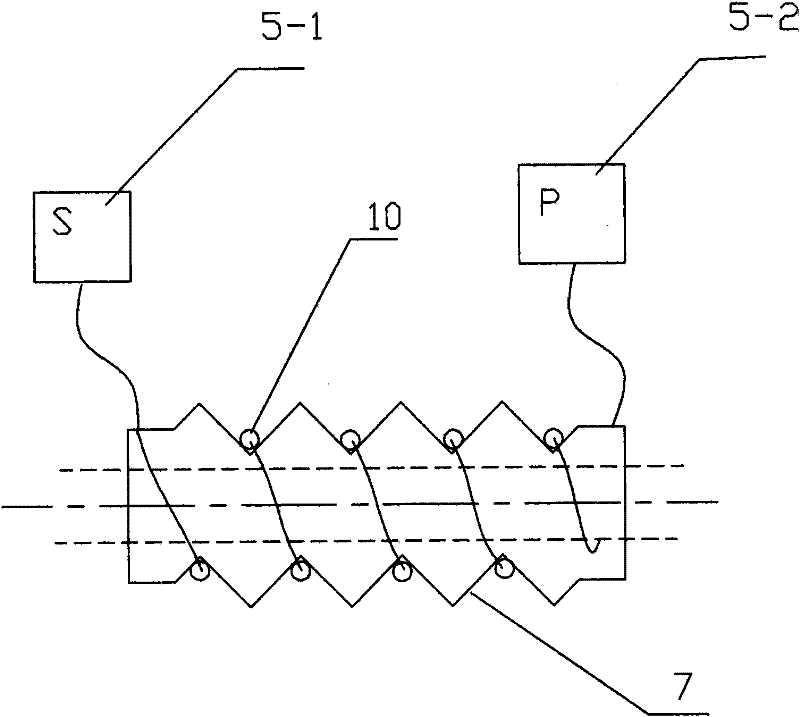

[0048] Such as Figure 6 , Figure 7 As shown, in this embodiment, the difference from Embodiment 2 is that the inner cylindrical body 11 is a cuboid, and positioning grooves 70 are arranged side by side on the opposite two surfaces of the cuboid, and a part of the signal optical fiber 10 is fixed on the In the positioning groove 70, there are grooves 40 on the outer surface of the inner cylindrical body vertically distributed on the surface of the inner cylindrical body 11 with the positioning groove 70, and the outer surface grooves of the inner cylindrical body are arranged on the inner surface of the housing 12 correspondingly. The groove 35 on the inner surface, the signal optical fiber 10 is sandwiched between the grooves of the groove 40 on the outer surface of the inner cylinder and the grooves of the groove 35 on the inner surface of the housing.

[0049] When the inner cylindrical body 11 is crystal and the housing 12 is quartz glass, and the X-axis direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com