Electromechanical device

A technology of electromechanical devices and electric power, applied in the direction of electromechanical devices, transmission devices, gear transmission devices, etc., can solve problems such as complex equipment, and achieve the effect of simple lubrication system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

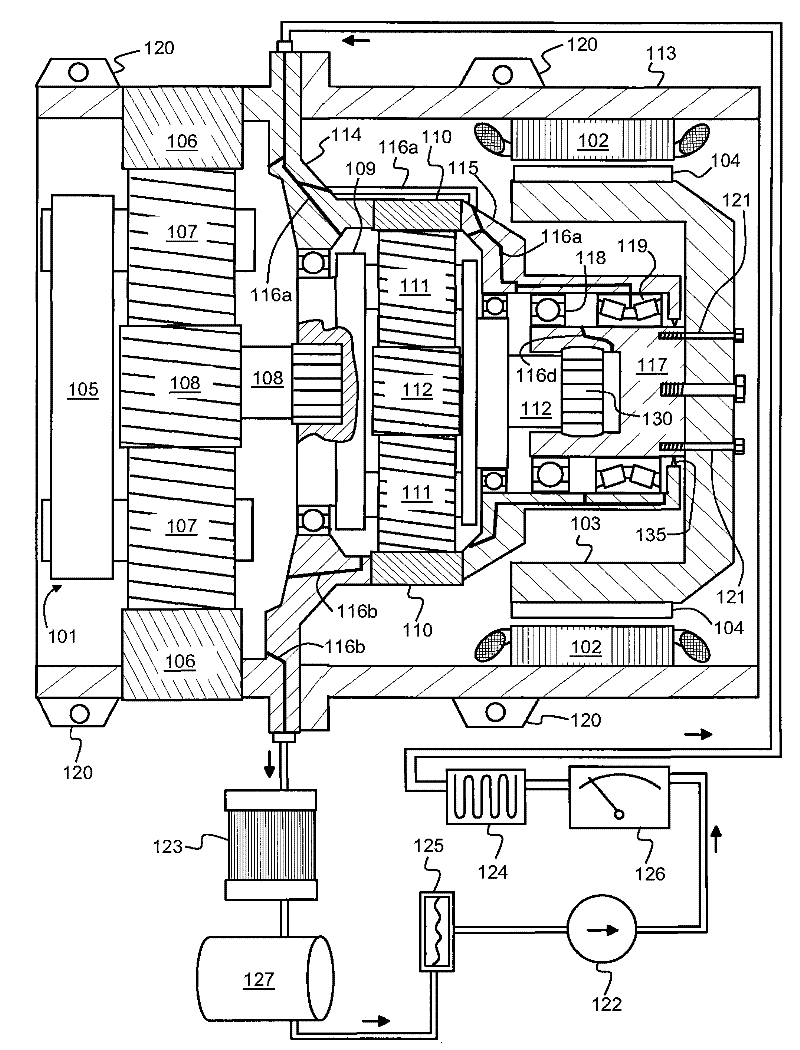

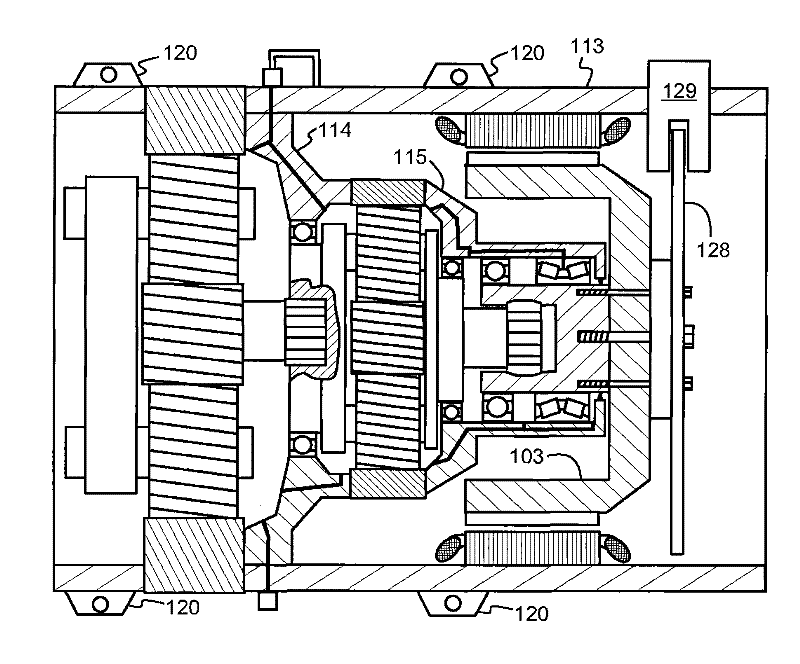

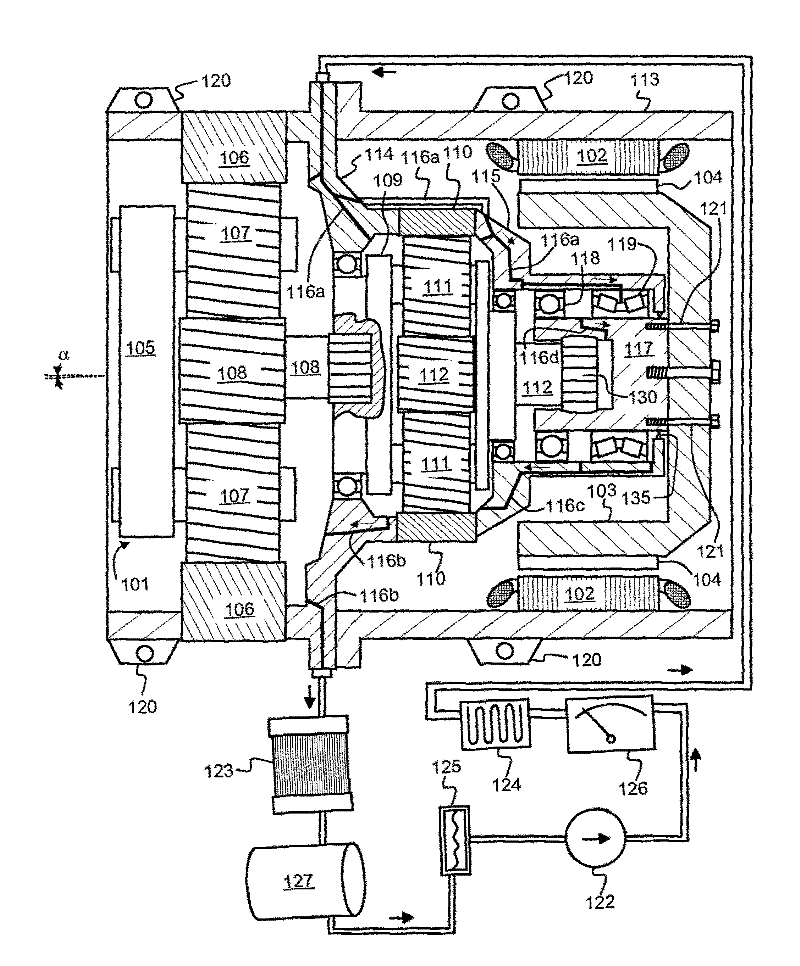

[0024] figure 1 A schematic cross-sectional view of an electromechanical device according to an advantageous exemplary embodiment of the invention is shown. The electromechanical device comprises a mechanical interface structure 101 for connection to an external rotating element, which can be, for example but not necessarily, a wind turbine. The electromechanical device includes an electric machine for converting mechanical power into electrical power or converting electrical power into mechanical power. The electric machine comprises a laminated stator core 102 provided with stator windings. The electric machine comprises a rotor comprising a central part 117, a frame 103 and permanent magnets 104 mounted on the outer surface of the frame. Of course, it is also possible that the central portion 117 and the frame 103 are a single integral piece. The electromechanical device includes one or more gear stages in the power transmission path between the mechanical interface stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com