Tower-like ultrasonic motor with asymmetrical structure and asymmetrical modes thereof as well as electric excitation mode of asymmetrical modes

An asymmetric structure, ultrasonic motor technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the error, adverse motor mechanical output performance, resonance frequency difference And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

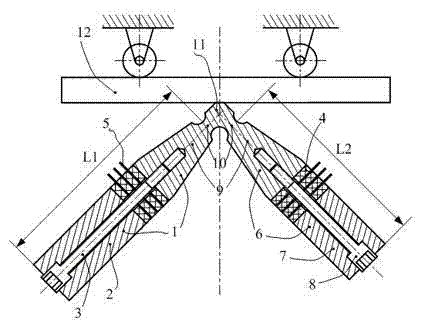

[0033] An asymmetric structure similar to the tower-shaped ultrasonic motor and its asymmetric mode and electric excitation method are as follows: figure 1 As shown, it is composed of a stator and a mover, wherein the mover is a linear guide rail 12 . Its characteristic is: under the action of pre-pressure, the guide rail 12 is pressed on the stator driving foot 11 . The stator includes a first piezoelectric vibrator 1 with a length of L1 and a second piezoelectric vibrator 6 with a length of L2, where L1>L2; the first piezoelectric vibrator 1 sequentially includes a first rear end cover 2, piezoelectric ceramics 4 and electrodes sheet 5, front end cover 9, front end cover 9 and first rear end cover 2 are compressed and fixed by first compression bolt 3; second piezoelectric vibrator 6 includes second rear end cover 7, piezoelectric ceramic 4 and electrode sheet in turn 5. The front end cover 9, the front end cover 9 and the second rear end cover 7 are compressed and fixed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com