Powder of lithium complex compound particles, method for producing the same, and nonaqueous electrolyte secondary cell

一种制造方法、化合物的技术,应用在非水电解质蓄电池、二次电池、镍化合物等方向,能够解决电阻上升、电池特性劣化等问题,达到提高涂装性、高温保存特性优异、循环特性良好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Lithium hydroxide is mixed with hydroxide containing cobalt, nickel, and aluminum so that the ratio of Li / (Ni+Co+Al) is 1.08, and fired at 750°C for 20 hours in an oxygen atmosphere to obtain lithium composite compound particles . 60 g of pulverized lithium composite compound particles were suspended in 300 ml of pure water at a water temperature of 10° C., stirred for 20 minutes, and then filtered and washed.

[0118] After drying overnight at 120°C, crush again, after decarbonation (CO 2 Heat treatment at 850° C. for 2 hours in an oxygen atmosphere with a concentration of 20 ppm).

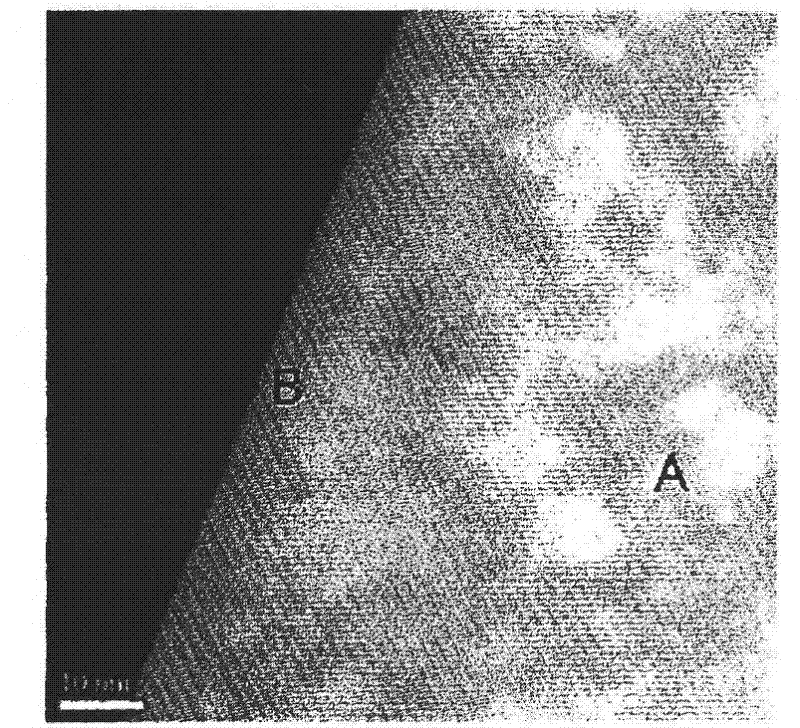

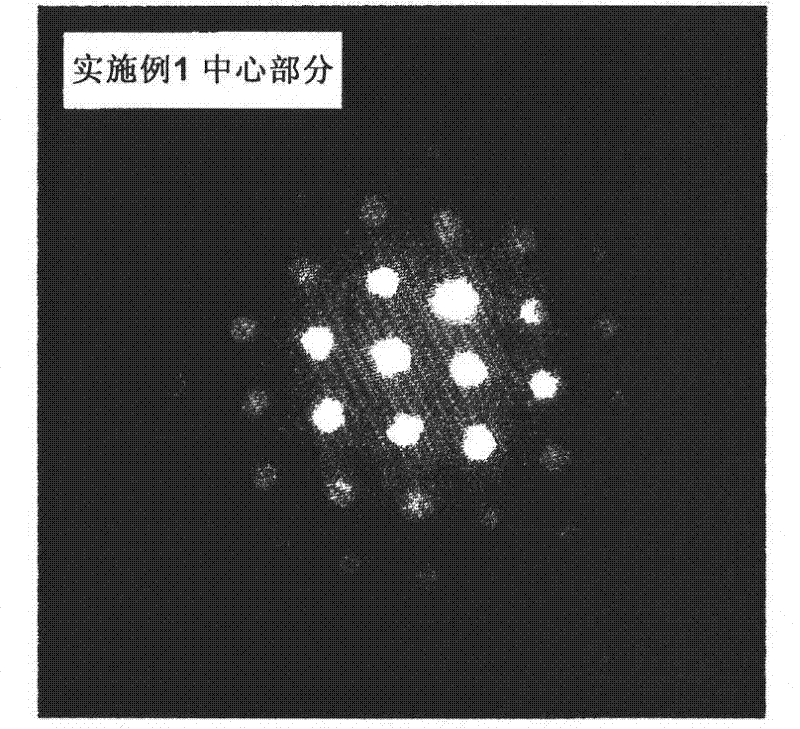

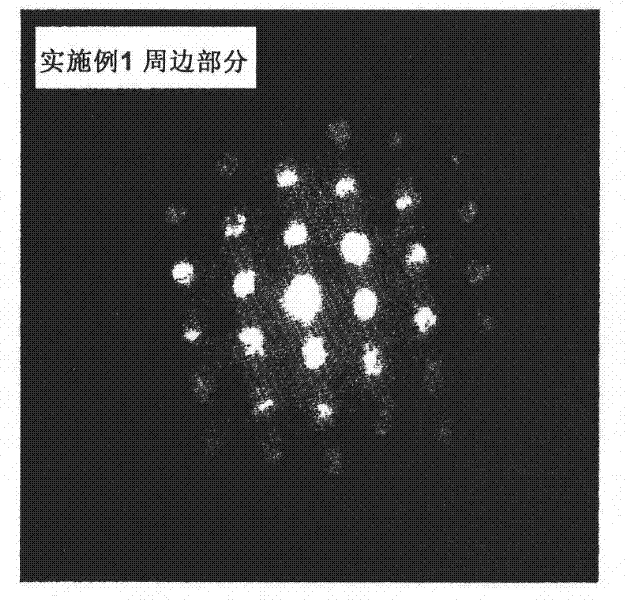

[0119] The obtained lithium composite compound particle powder was evaluated by a time-of-flight secondary ion mass spectrometer as the ionic strength ratio A(LiO - / NiO 2 - ) is 0.04, the ionic strength ratio B(Li 3 CO 3 + / Ni + ) is 3.8, the ionic strength ratio C(LiSO 3 - / NiO 2 - ) is 0.07. After embedding the obtained particles in resin, after performing FIB processing, i...

Embodiment 2

[0121] The powder obtained by mixing Li / (Ni+Co+Al) at a ratio of 1.02 and treating it in the same manner as in Example 1 was washed, dried, and heat-treated at 800°C in an oxygen atmosphere after decarbonation (concentration: 20ppm) 2 hours.

Embodiment 3

[0123] The powder obtained by mixing Li / (Ni+Co+Al) at a ratio of 1.02 and treating it in the same manner as in Example 1 was washed, dried, and heat-treated at 800°C in an air atmosphere after decarbonation (concentration: 20ppm) 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com