Three-eccentric cut-off butterfly valve of blast furnace

A triple eccentric, blast furnace technology, applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as economic loss, blast furnace shutdown, poor sealing performance, etc., to avoid severe erosion and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

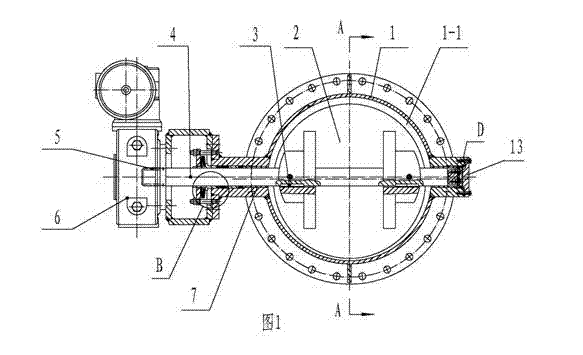

[0023] like figure 1 As shown, a blast furnace triple eccentric cut-off butterfly valve includes a valve body 1 and a valve stem 4 installed on the valve body 1, and a butterfly plate 2 that is fixedly connected with the valve stem 4 and rotates around the valve stem 4 in the valve cavity of the valve body 1. , a valve seat 1-1 is arranged in the valve chamber of the valve body 1 . The valve stem 4 is supported on the nano-plated self-lubricating bushing 7, and the bushing 7 has a self-lubricating function and does not need to be lubricated with any lubricant.

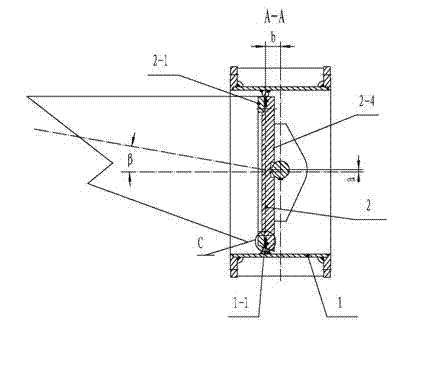

[0024] like figure 2 As shown, the valve body 1 is provided with a valve seat 1-1 welded on the inner wall of the valve body 1 . The valve seat 1-1 is made of stainless steel, which is resistant to erosion and oxidation.

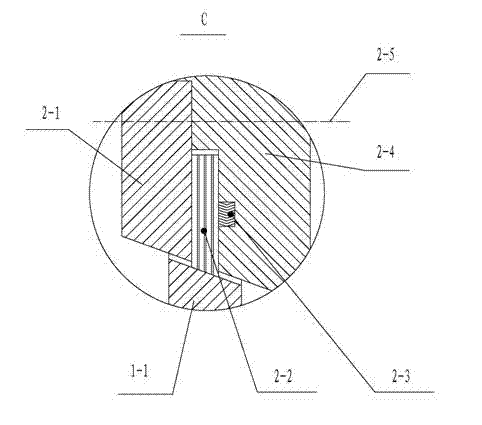

[0025] like image 3 As shown: the sealing structure of the blast furnace tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com