Carbon-based composite electrode material for super lead-acid battery and preparation method thereof

A technology for super lead-acid batteries and composite electrodes, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc. It can solve the problems of large difference in working potential range and supercapacitor electrodes can not work normally, and achieves a simple and easy preparation method , stable performance and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

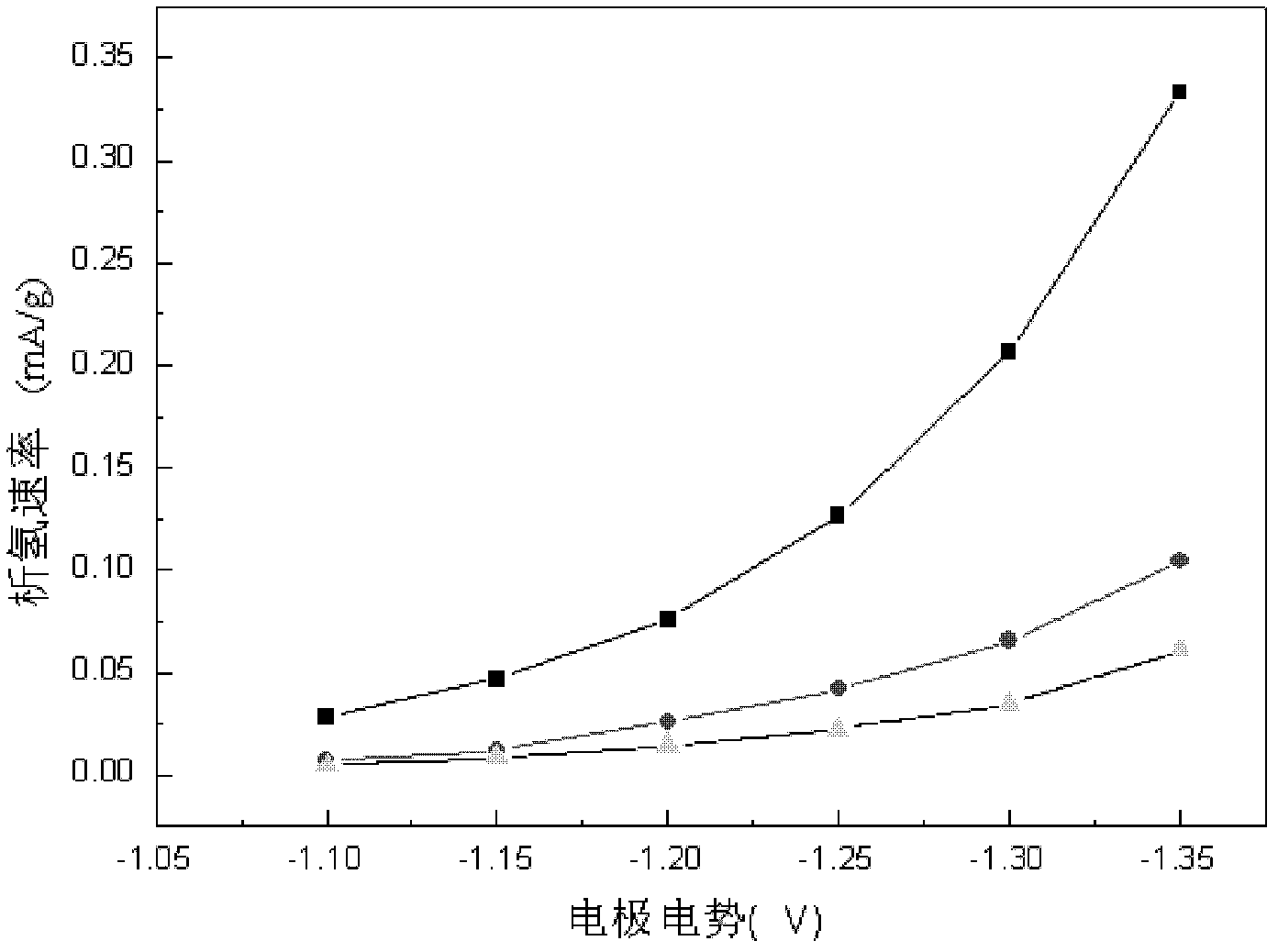

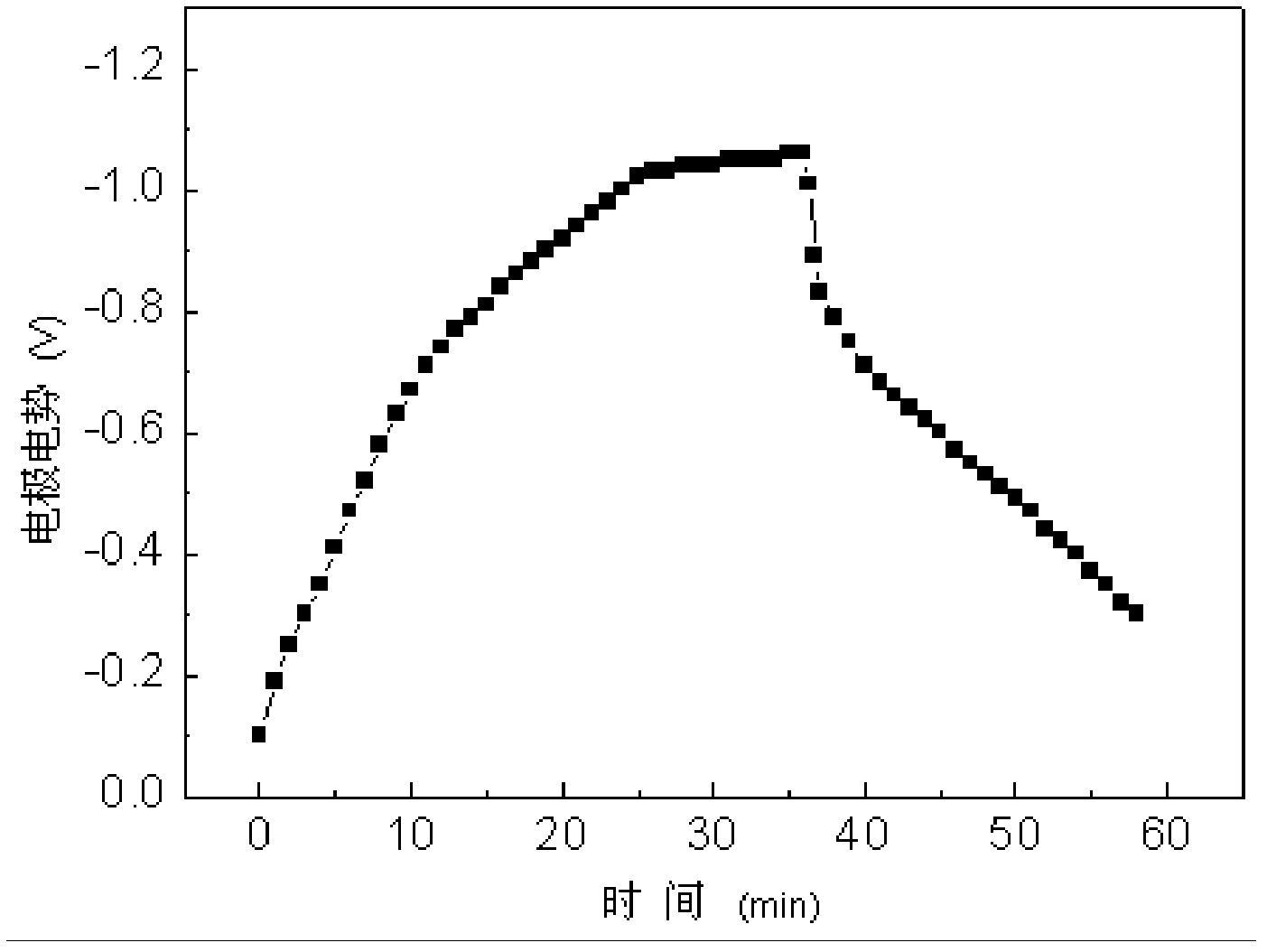

[0015] Embodiment 1: The carbon-based composite electrode material used for the super lead-acid battery of this embodiment consists of 10% to 91.9% porous carbon material, 8% to 80% PbSO 4 and 0.1% to 10% of the modification material, wherein the modification material is CdSO 4 、In 2 (SO 4 ) 3 , ZnSO 4 , SnSO 4 or Bi 2 (SO 4 ) 3 , modified materials or by mass percentage from 25% to 75% In 2 (SO 4 ) 3 and Bi from 25% to 75% 2 (SO 4 ) 3 Composition, modified material or ZnSO by mass percentage from 25% to 75% 4 and 25% to 75% of SnSO 4 Composition, modified materials or by mass percentage from 10% to 30% In 2 (SO 4 ) 3 , 10% to 30% Bi 2 (SO 4 ) 3 , 10% ~ 30% ZnSO 4 and 10% to 70% of CdSO 4 Composition; the porous carbon material is activated carbon, activated carbon fiber, activated carbon felt, mesoporous carbon or carbon nanotube.

[0016] In this embodiment, the porous carbon material is first impregnated with a soluble salt solution of lead element, s...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the carbon-based composite electrode material used for super lead-acid batteries consists of 29% to 84% porous carbon material and 15% to 70% PbSO by mass percentage 4 And 1% to 9% of modified materials. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the carbon-based composite electrode material used for super lead-acid batteries consists of 50% porous carbon material, 45% PbSO by mass percentage 4 and 5% modifier material. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com