Method for manufacturing carbon fiber reinforced lead alloy plate grid and winding lead-acid battery

A manufacturing method and technology of lead-acid batteries, applied to battery components, circuits, electrical components, etc., can solve the problems of ineffective coating of active materials, low weight specific energy of lead-acid batteries, and easy damage of wound battery grids and other problems, to achieve the effect of good high-current discharge performance, flexible placement and matching, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

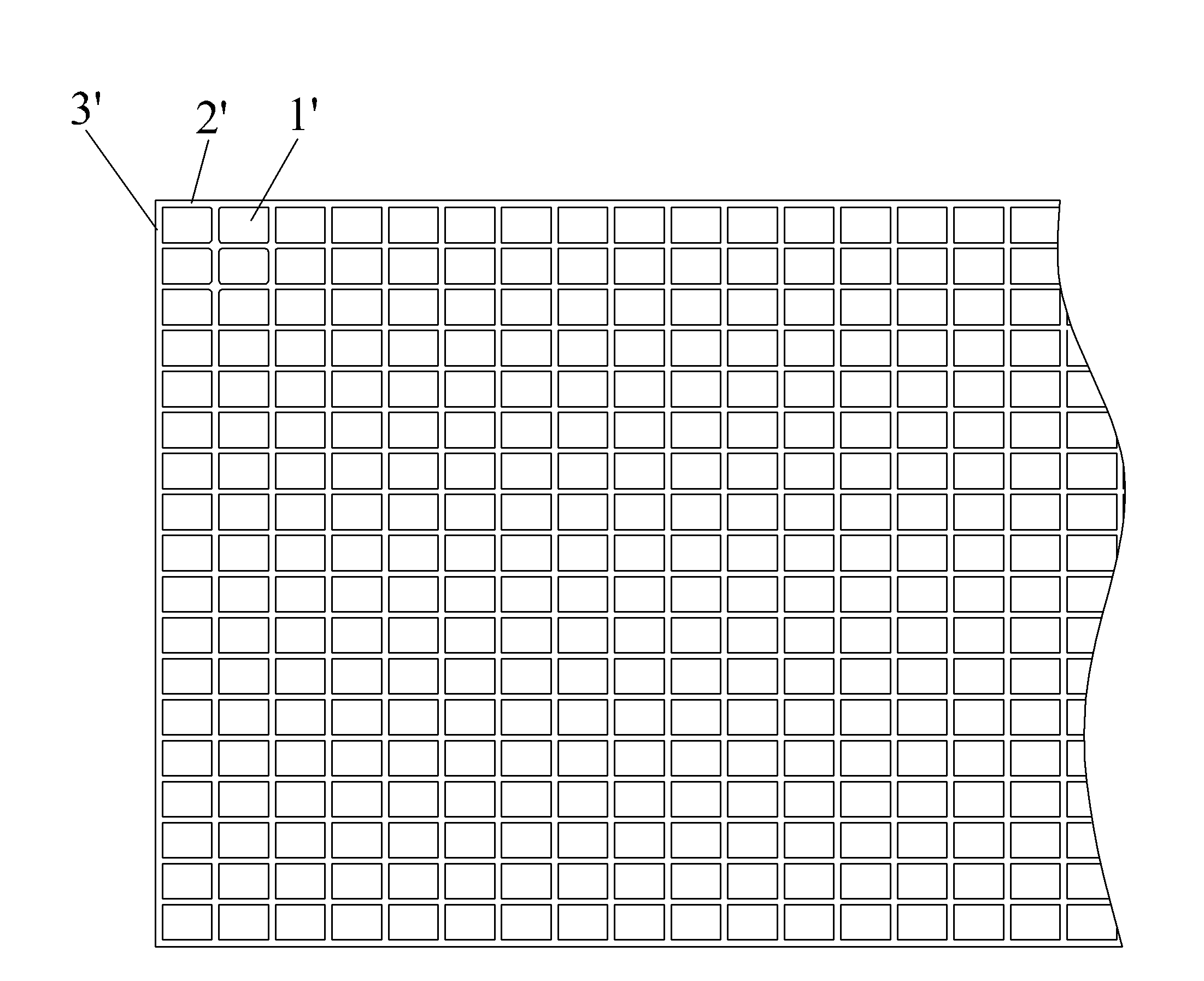

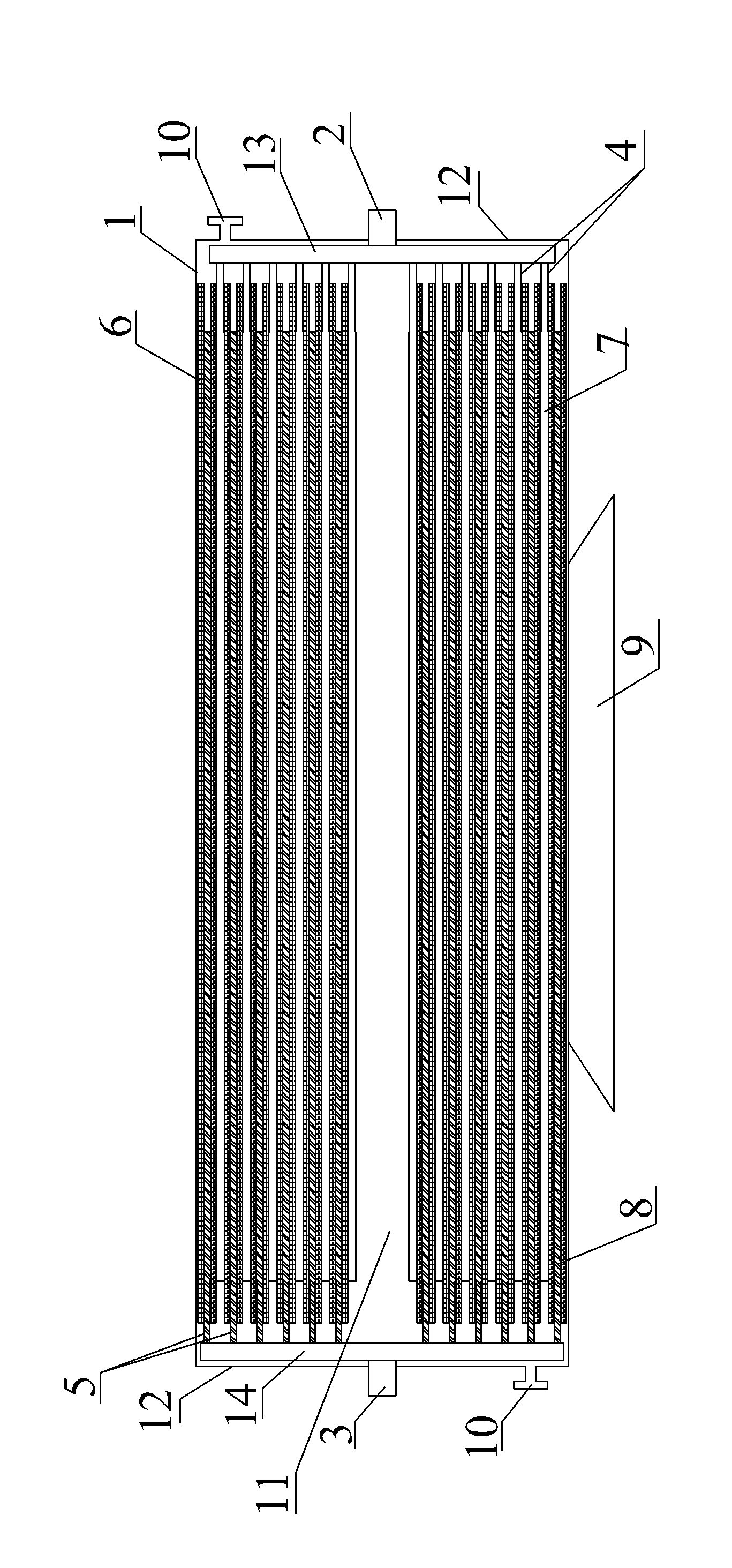

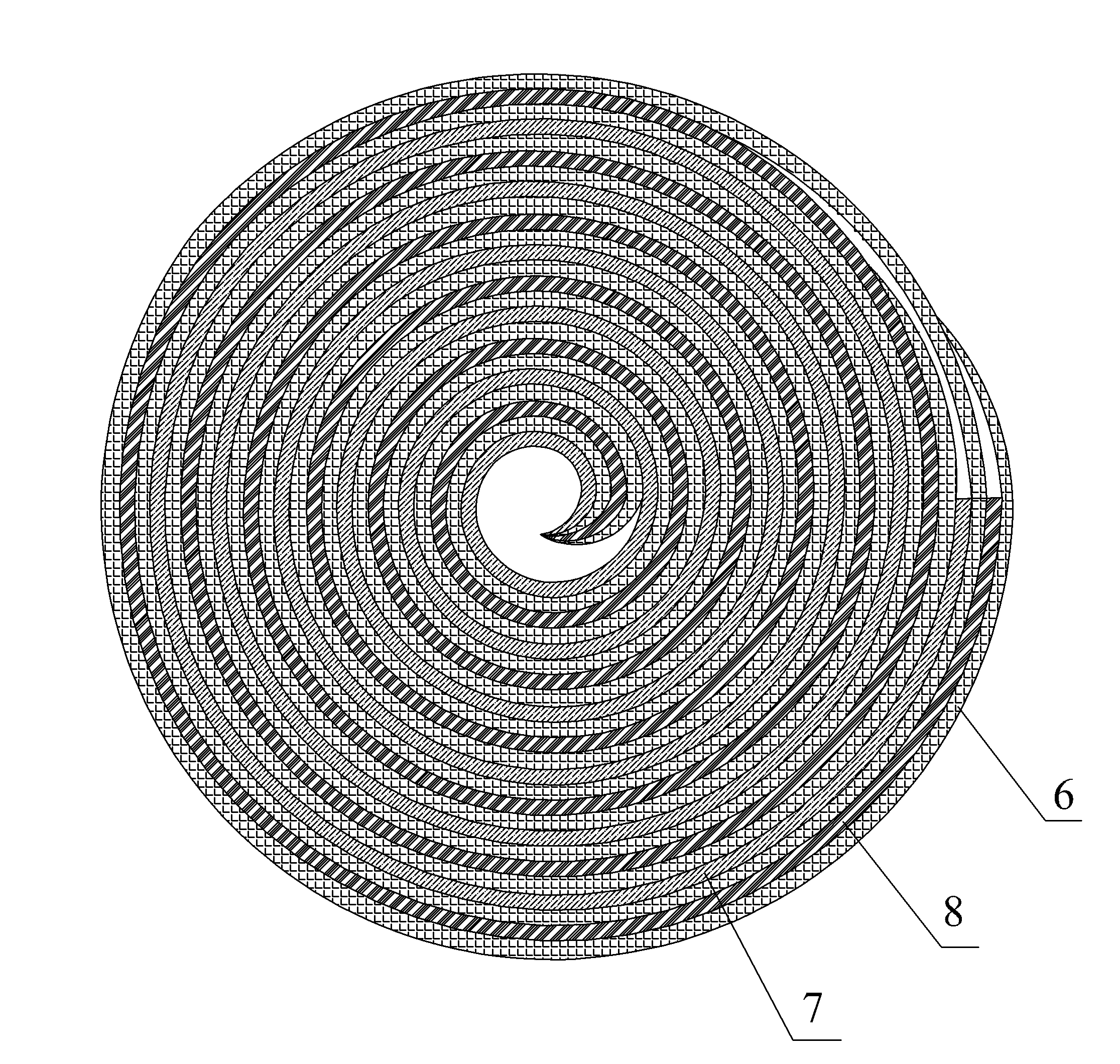

[0030] Embodiment one: the manufacture method of carbon fiber reinforced lead alloy grid, it follows the steps:

[0031] (1) High-temperature degumming of carbon fiber cloth: carbon fiber cloth is made of unidirectional long carbon fibers (only warp threads, no weft threads) and epoxy resin. The carbon fibers are placed in an environment of 480 ° C and baked for 7 minutes to remove epoxy resin.

[0032] (2) Carbon fiber impregnation: Under the protection of anhydrous and inert gas, immerse the carbon fiber cloth degummed in step (1) into the liquid sodium-potassium alloy for 2 minutes at room temperature, and then slowly pull out the carbon fiber cloth.

[0033] (3) Hot extrusion molding: After the carbon fiber cloth is impregnated in step (2), it is quenched together with lead or lead alloy liquid under high temperature and high pressure (540°C, 510Mpa) to below 200°C, and extruded A plate with a thickness of 1.0 mm was made. The lead can be 1# lead, and the lead alloy can b...

Embodiment 2

[0039] Embodiment two: the manufacture method of carbon fiber reinforced lead alloy grid, it follows the steps:

[0040] (1) High-temperature degumming of carbon fiber cloth: carbon fiber cloth is made of unidirectional long carbon fibers (only warp threads, no weft threads) and epoxy resin, and the carbon fibers are placed in an environment of 455°C and baked for 9 minutes to remove epoxy resin.

[0041](2) Carbon fiber impregnation: Under the protection of anhydrous and inert gas, at room temperature, immerse the carbon fiber cloth degummed in step (1) into the liquid sodium-potassium alloy for 1.5 minutes, and then slowly pull out the carbon fiber cloth.

[0042] (3) Hot extrusion molding: After the carbon fiber cloth is impregnated in step (2), it is quenched together with lead or lead alloy liquid under high temperature and high pressure (460°C, 540Mpa) to below 200°C, and extruded A plate with a thickness of 1.0 mm was made. The lead can be 1# lead, and the lead alloy c...

Embodiment 3

[0045] Embodiment three: the manufacturing method of carbon fiber reinforced lead alloy grid, it follows the steps:

[0046] (1) High-temperature degumming of carbon fiber cloth: carbon fiber cloth is made of unidirectional long carbon fibers (only warp threads, no weft threads) and epoxy resin, and the carbon fibers are arranged in an environment of 495°C and baked for 5 minutes to remove epoxy resin.

[0047] (2) Carbon fiber impregnation: Under the protection of anhydrous and inert gas, at room temperature, immerse the carbon fiber cloth degummed in step (1) into the liquid sodium-potassium alloy for 3 minutes, and then slowly pull out the carbon fiber cloth.

[0048] (3) Hot extrusion molding: After the carbon fiber cloth is impregnated in step (2), it is quenched together with lead or lead alloy liquid under high temperature and pressure (500°C, 530Mpa) to below 200°C, and extruded A plate with a thickness of 1.0 mm was made. The lead can be 1# lead, and the lead alloy c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com