Method for cleaning object and system for cleaning object

A technology for objects and nozzles, applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., which can solve problems such as treatment time limit soaking time, inability to sufficiently remove dirt, and insufficient cleaning power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

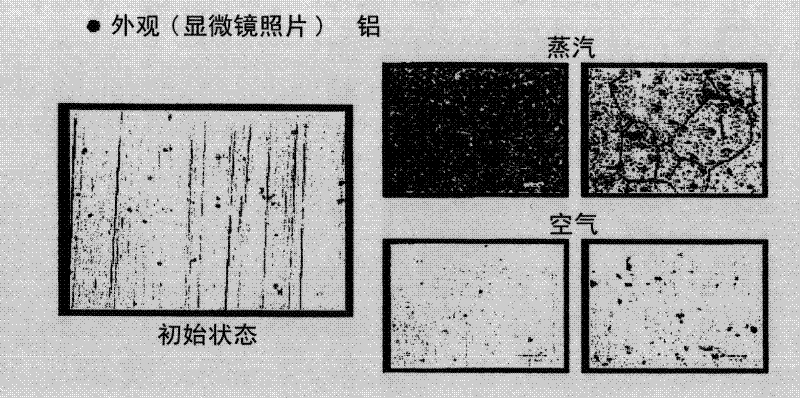

[0127] Under the following conditions, a miscible fluid (in the case of using steam as the gas and in the case of using air as the gas) was irradiated on the aluminum surface for 10 minutes. image 3 The middle represents AFM pictures before and after processing. Figure 5 represents the surface roughness data. In addition, in this example, surface roughness was measured by the method of the appearance (profile) analysis attached to AFM.

[0128] Steam pressure: 0.2MPa

[0129] Steam temperature: 130°C

[0130] Pure water flow: 300cc / min

[0131] Pure water temperature: 20°C

[0132] Gap: 5mm

[0133] Nozzle Scanning: Fixed

example 2

[0135] Under the same conditions as in Example 1, the steel surface was irradiated with a miscible fluid for 10 minutes (in the case of using steam as the gas and in the case of using air as the gas). Figure 4 The middle represents AFM pictures before and after processing. Figure 6 represents the surface roughness data.

example 3

[0137] Since the steam cleaning technique disclosed in Patent Document 1 strips the resist through the chemical reaction of the steam and the mechanical action of the jet, it takes a fractional amount of time to strip the resist. In order to confirm whether this method also has the same mechanism, visualization with a high-speed camera was performed. The mixed-phase fluid was irradiated under the same conditions as in Example 1 except that the nozzle scanning speed was 100mm / sec, Figure 7 The middle shows the time-lapse of i-line positive resist peeling observed from the lower part of the quartz wafer. As shown in the figure, the resist is stripped at a very high speed while the stripped region gradually expands.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com