Double laser beam welding method for reducing T-shaped joint welding deformation

A laser beam welding and laser beam technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as reducing welding deformation, and achieve the effect of reducing welding deformation, ensuring welding quality, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

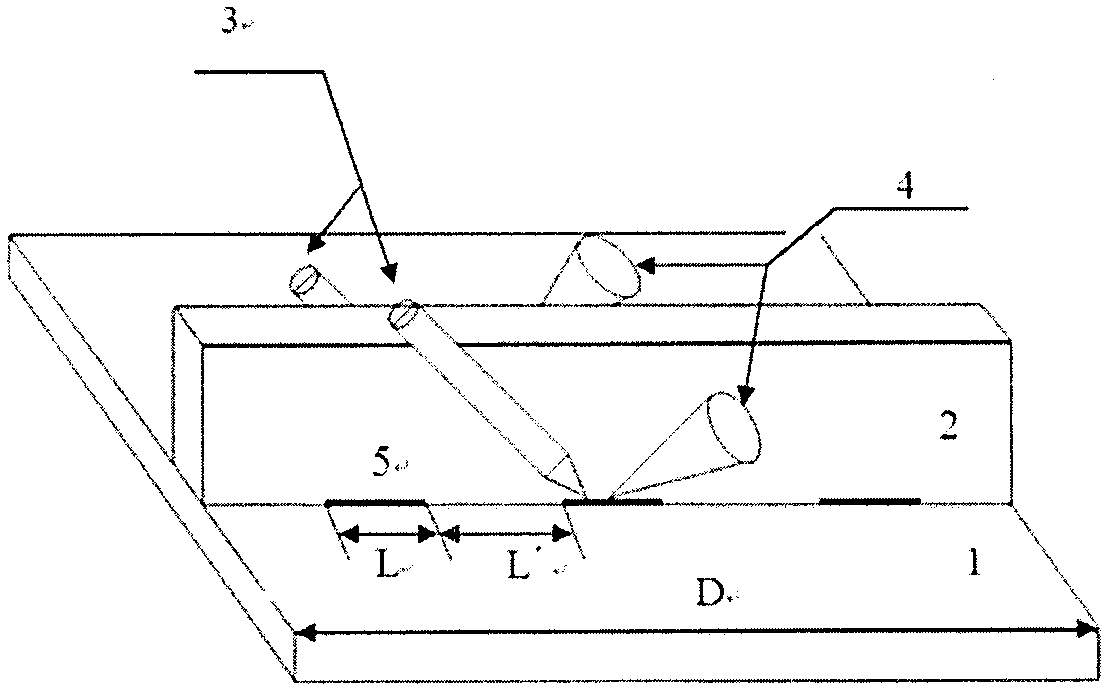

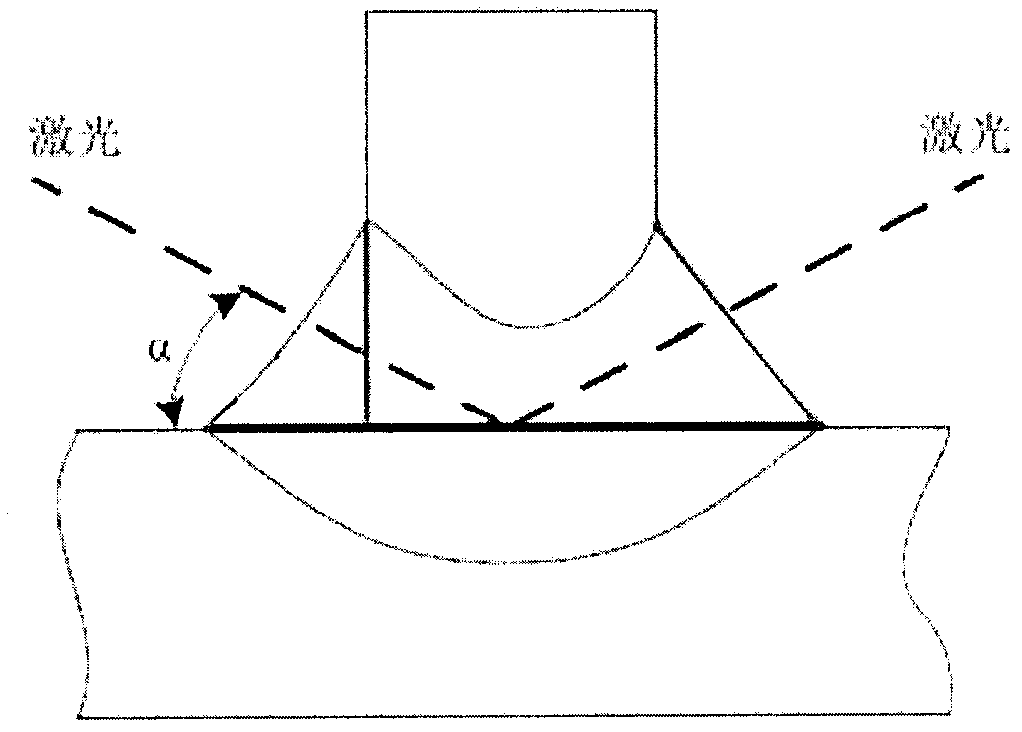

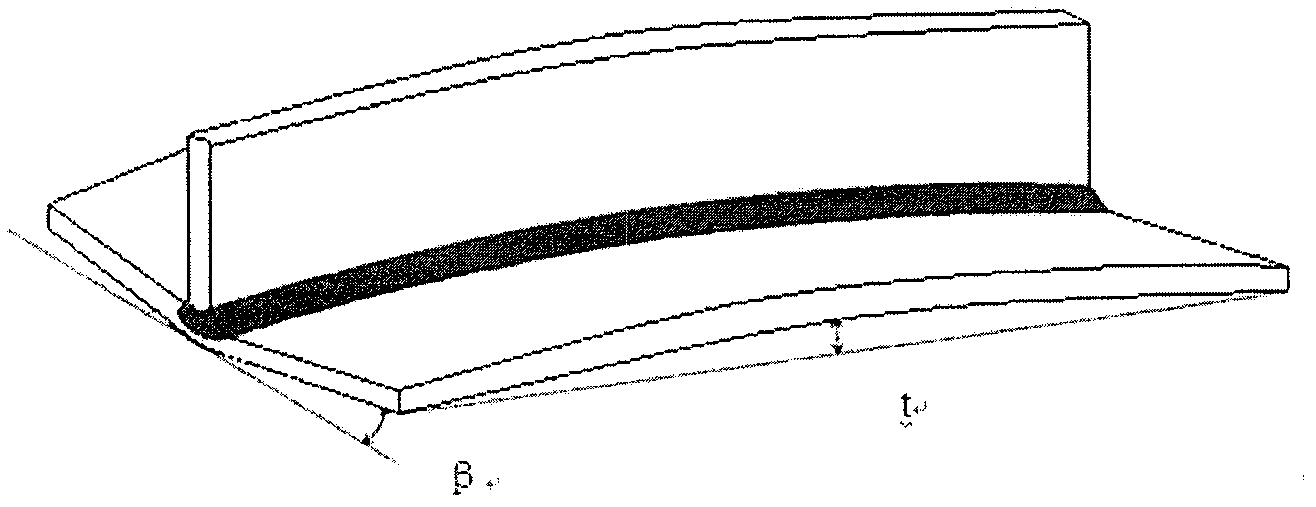

[0023] see figure 1 with figure 2 , which shows a schematic diagram and a partial cross-sectional view of tack welding an aluminum alloy T-joint. First, the skin 1 and the stringer 2 that have been pre-welded are fixed on the workbench by a fixture, and the joint form between them is a T-joint, and the length of the entire T-joint is D. The shielding gas nozzle 4 is set so that it is located directly behind the laser beam 3 to be emitted along the welding direction, and then, two lasers (not shown) are symmetrical to both sides of the aluminum alloy T-shaped joint of the skin 1-long stringer 2 spot welding to form several tack welds 5 with a certain length L (in figure 1 , schematically shows three tack welds), and there is a certain interval L' between adjacent tack welds 5. Next, two lasers are used to carry out synchronous and continuous welding on both sides of the T-shaped joint with two laser beams. In this way, the tack welding seam 5 is covered by the continuousl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle of incidence | aaaaa | aaaaa |

| Laser power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com