Finger device for double-joint three-axis-wheel combined underactuated robot

A robotic finger and underactuated technology, applied in the field of humanoid robotic hands, can solve the problems of difficult end pinching and grasping effects, large deformation of multiple spring parts, lack of self-adaptability, etc., to achieve convenient assembly and maintenance and low energy consumption small, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

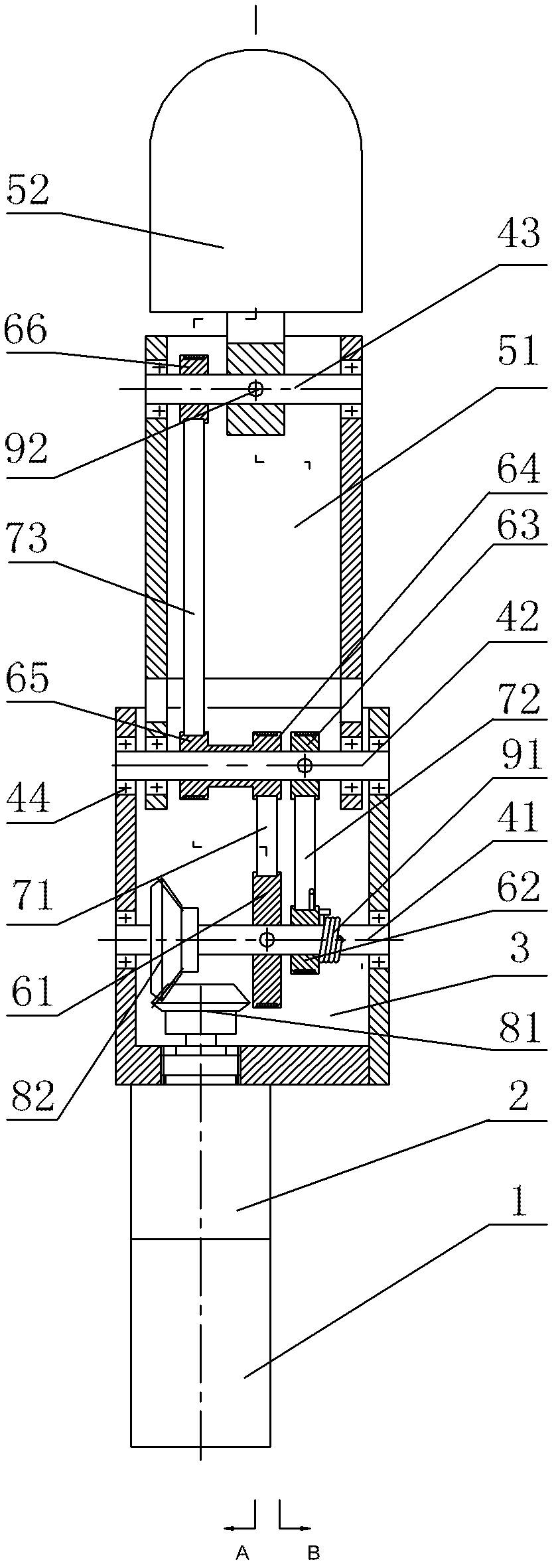

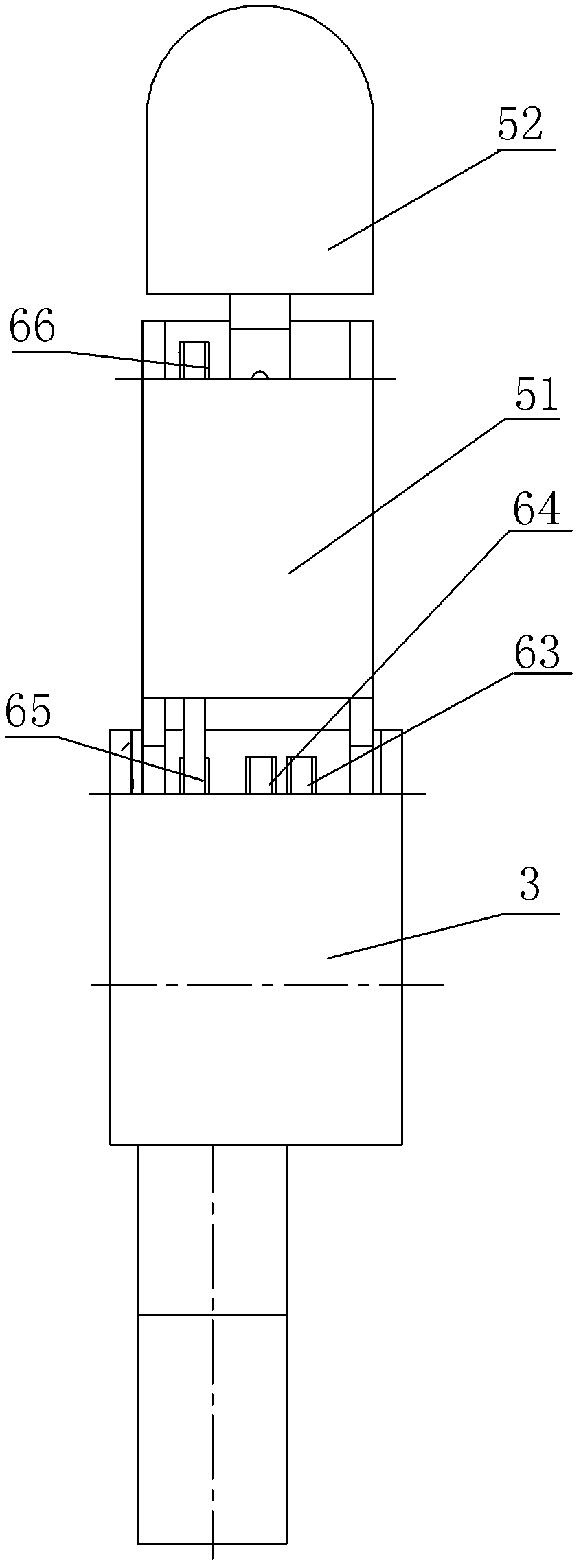

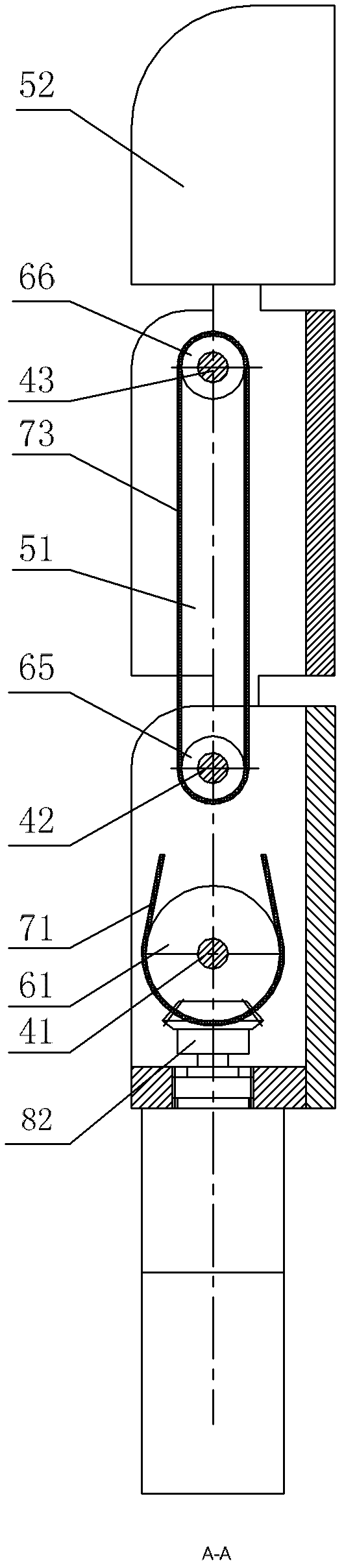

[0043] An embodiment of the double-joint three-axis wheel type compound underactuated robot finger device of the present invention, such as Figure 1 to Figure 4 As shown, the robotic finger device includes a motor 1, a reducer 2, a base 3, a proximal joint shaft 42, a distal joint shaft 43, a middle finger segment 51 and an end finger segment 52; the motor 1 and the reducer 2 are fixedly connected On the base 3, the output shaft of the motor is connected with the input shaft of the reducer; the proximal joint shaft 42 is movably sleeved in the base 3, and the distal joint shaft 43 is movably sleeved in the middle finger section 51; The middle finger segment 51 is sleeved on the proximal joint shaft 42 ; the end finger segment 52 is sleeved on the distal joint shaft 43 .

[0044] This embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com