Ferromagnetic semiconductor crystal and preparation method thereof

A semiconductor and ferromagnetic technology, applied in the field of ferromagnetic semiconductor crystals and its preparation, can solve the problems of difficult research and influence of physical mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In a glove box filled with argon gas, the Zn powder, Mn powder, and As powder with a purity of 99.9% or above were uniformly mixed at a molar ratio of 0.9:0.1:1, and pressed into a small disc of the mixture. Then weigh the Li block according to the molar ratio of Li:Zn:Mn:As = 1.1:0.9:0.1:1, and put the small disc of the mixture into the alumina ceramic test tube together with the Li block; The test tube is packaged in a quartz tube, and the inside of the quartz tube is evacuated, and then 0.2 Bar of argon gas is filled in the quartz tube and sealed. Next, it is sintered at a temperature of 900° C. in a high-temperature furnace for 5 hours.

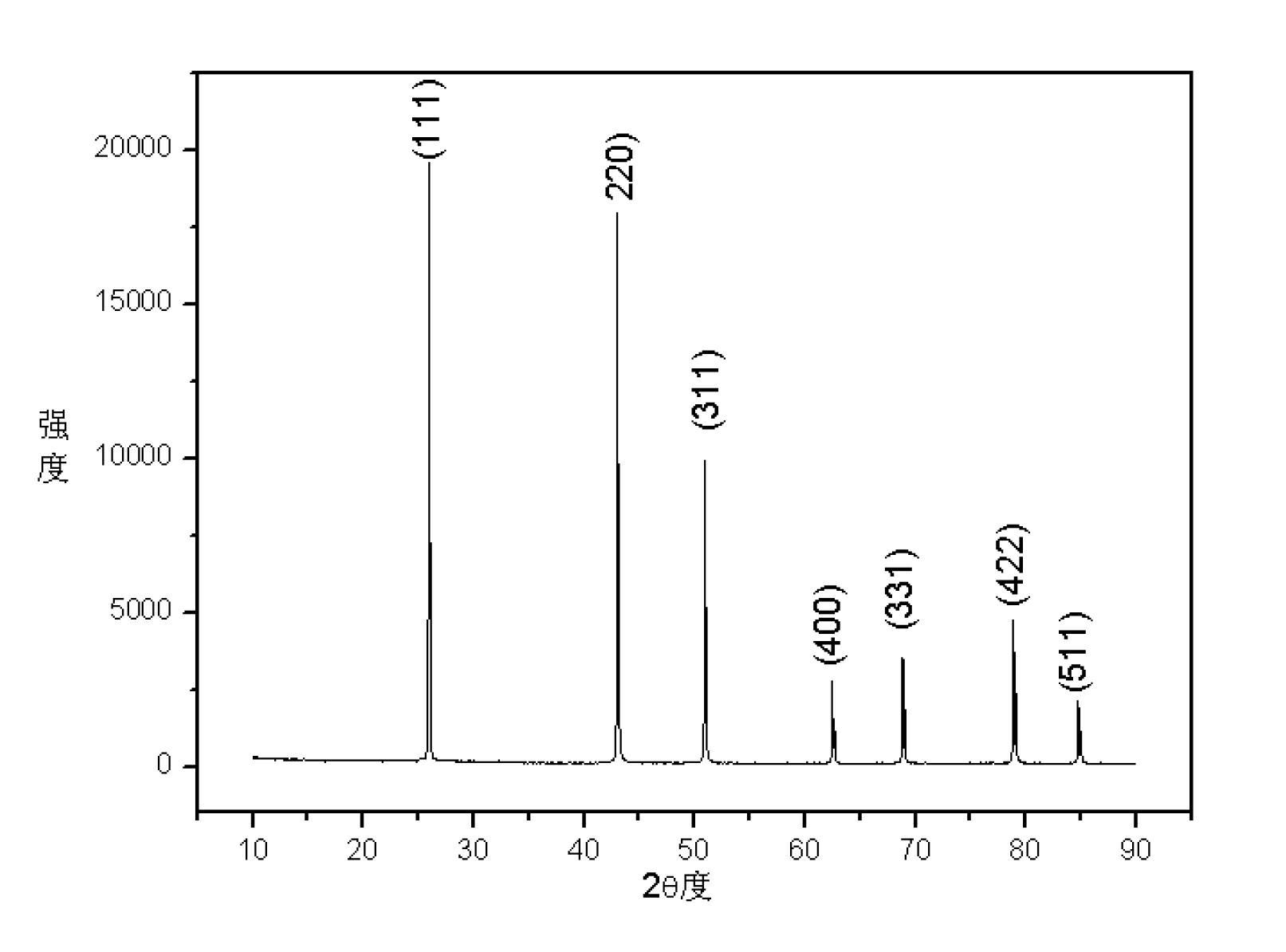

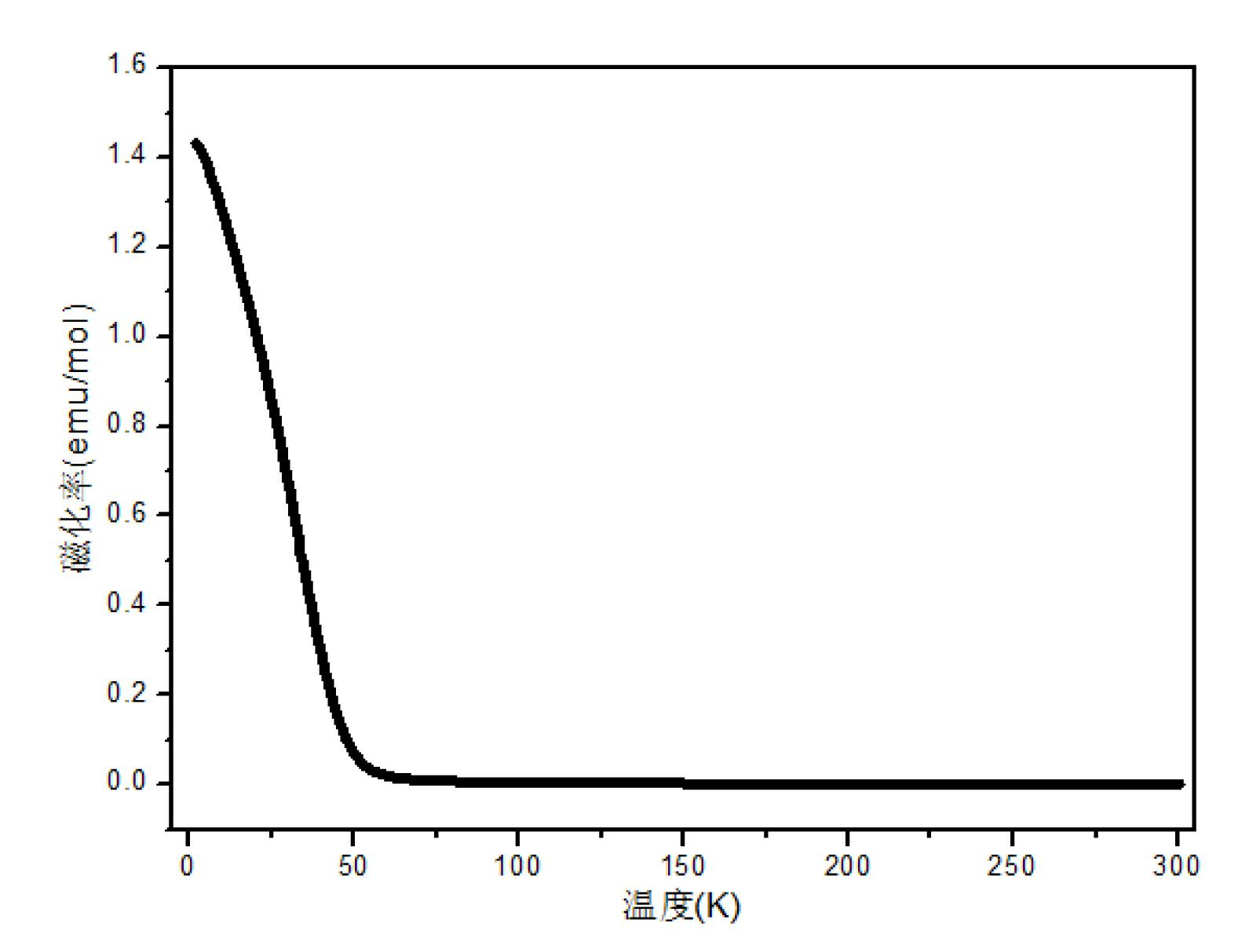

[0027] Finally, the sample was taken out, and the measurement experiments of X-ray diffraction and DC magnetic susceptibility were carried out on the sample respectively, and the results were as follows: figure 1 and figure 2 shown. Its ferromagnetic transition temperature is 50K.

[0028]

Embodiment 2

[0030] Using the solid-state reaction method under normal pressure, Zn powder and As powder with a purity of 99.9% or above are mixed at a molar ratio of 1:1, pressed into tablets, and packaged in a vacuum quartz tube, sintered at 900°C, and kept warm After 48 hours, a single-phase ZnAs compound can be prepared. Single-phase MnAs compounds were also obtained in the same manner.

[0031] In a glove box filled with argon gas, Li blocks were then weighed according to the molar ratio of Li:ZnAs:MnAs=1.5:0.8:0.2, and put together into alumina ceramic test tubes; then the ceramic test tubes containing samples were put into quartz The inside of the tube was evacuated, and then the quartz tube was filled with 0.5 Bar argon gas and sealed. Next, it is sintered in a high-temperature furnace at a temperature of 1000° C. for 30 hours.

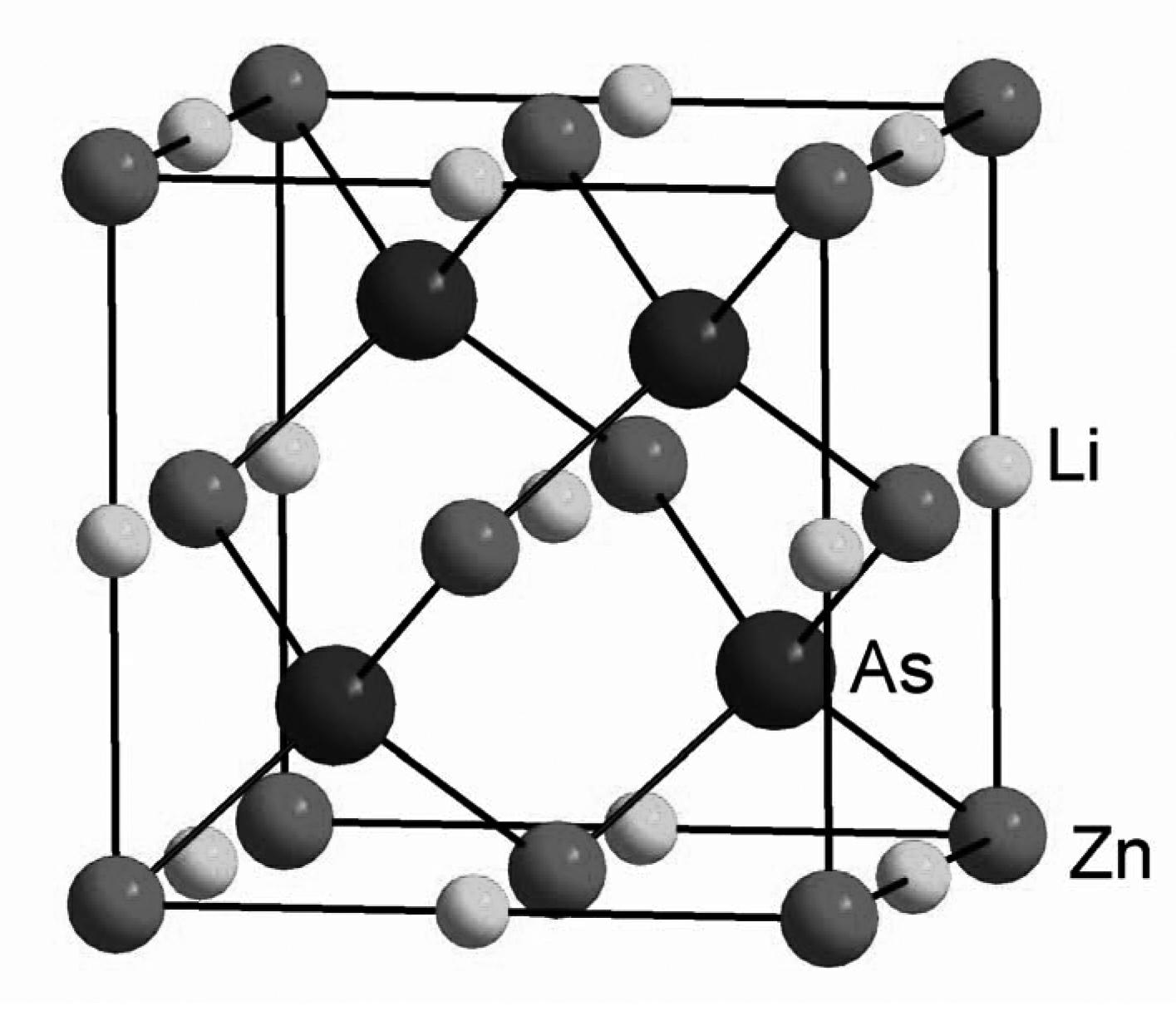

[0032] Finally got Li y (Zn 1-x mn x ) As crystal. The experiment carried out structural refinement on the X-spectrum of the sample, and obtained it...

Embodiment 3

[0035] According to the steps of Example 2, ZnAs and MnAs precursors were prepared.

[0036] In a glove box filled with argon gas, Li blocks were then weighed according to the molar ratio of Li:ZnAs:MnAs=0.5:0.7:0.3, and put into alumina ceramic test tubes together; The inside of the tube was evacuated, and then the quartz tube was filled with 0.2 Bar argon gas and sealed. Next, it is sintered at 600° C. for 10 hours in a high-temperature furnace. Finally also get Li y (Zn 1-x mn x ) As crystal.

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com