Ultraviolet and stain resistant natural stone paint and preparation method thereof

A stain-resistant, real stone paint technology, applied to biocide-containing paints, anti-fouling/underwater paints, coatings, etc., can solve problems such as dust accumulation, improper aggregate gradation, and difficult to remove stains, etc., to achieve Effect of improving stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

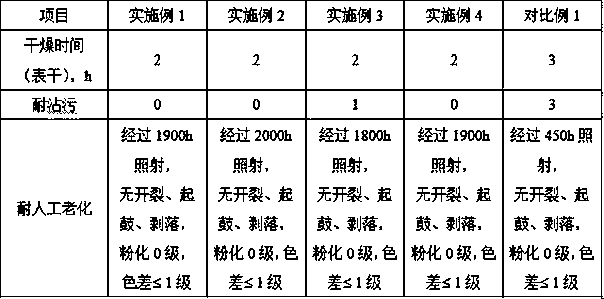

Embodiment 1

[0095] An anti-ultraviolet and stain-resistant real stone paint, comprising the following components in parts by weight:

[0096] TiO 2 @Ti 0.75 (OH) 1.5 Cl 1.5 Nanoparticles A13 parts

[0097] Silicone-polyacrylate 20 parts

[0098] 10-20 mesh 3 parts

[0099] 20-40 mesh 6 parts

[0100] 40-80 mesh 10 copies

[0101] 80-120 mesh 16 parts

[0102] 120-180 mesh 25 parts

[0103] 1 part film-forming aid

[0104] Thickener 0.05 parts

[0105] Dispersant 0.2 parts

[0106] 0.2 part of defoamer

[0107] Preservative 0.1 parts

[0108] 0.05 parts of pH regulator

[0109] 8 parts of deionized water;

[0110] Concrete preparation steps are as follows:

[0111] Add deionized water into the container, stir at a speed of 300rpm, then add silicone-polyacrylate, dispersant, defoamer, and viscous agent, adjust the speed to 900rpm, and stir for 5 minutes. Adjust the speed to 500rpm, add aggregate, TiO 2 @Ti 0.75 (OH) 1.5 Cl 1.5 Nanoparticle A1, then adjust the rotation s...

Embodiment 2

[0113] An anti-ultraviolet and stain-resistant real stone paint, comprising the following components in parts by weight:

[0114] TiO 2 @Ti 0.75 (OH) 1.5 Cl 1.5 Nanoparticles A29 parts

[0115] Silicone-polyacrylate 16 parts

[0116] Polyurethane-polyacrylate 8 parts

[0117] 10-20 mesh 6 parts

[0118] 20-40 mesh 8 parts

[0119] 13 copies of 40-80 mesh

[0120] 80-120 mesh 21 parts

[0121] 120-180 mesh 34 pieces

[0122] Coalescing aid 1.5 parts

[0123] Thickener 0.15 parts

[0124] Dispersant 0.2 parts

[0125] 0.2 part of defoamer

[0126] Preservative 0.1 parts

[0127] 0.05 parts of pH regulator

[0128] 10 parts of deionized water;

[0129] Concrete preparation steps are as follows:

[0130] Add deionized water into the container, stir at 300rpm, then add silicone-polyacrylate, polyurethane-polyacrylate, dispersant, defoamer, viscous agent, adjust the speed to 1000rpm, and stir for 5 minutes. Adjust the speed to 400rpm, add aggregate, TiO 2 @Ti 0.75 ...

Embodiment 3

[0132] An anti-ultraviolet and stain-resistant real stone paint, comprising the following components in parts by weight:

[0133] TiO 2 @Ti 0.75 (OH) 1.5 Cl 1.5 Nanoparticles A35 parts

[0134] Polystyrene-polyacrylate 20 parts

[0135] 10-20 mesh 4 copies

[0136] 20-40 mesh 7 parts

[0137] 40-80 mesh 11 parts

[0138] 80-120 mesh 17 parts

[0139] 120-180 mesh 28 parts

[0140] 1 part film-forming aid

[0141] Thickener 0.05 parts

[0142] Dispersant 0.2 parts

[0143] 0.1 part of defoamer

[0144] Preservative 0.1 parts

[0145] 0.05 parts of pH regulator

[0146] 9 parts of deionized water;

[0147] Concrete preparation steps are as follows:

[0148] Add deionized water into the container, stir at a speed of 300rpm, then add polystyrene-polyacrylate, dispersant, defoamer, and viscous agent, adjust the speed to 900rpm, and stir for 5 minutes. Adjust the speed to 500rpm, add aggregate, TiO 2 @Ti 0.75 (OH) 1.5 Cl 1.5 Nanoparticle A3, then adjust the rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com