Detection system for tamping settlement of heavy tamping machine

A detection system and tamping technology, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc., can solve the problems of high labor intensity, large impact on the vehicle body, troublesome detection, etc., achieve high detection accuracy and avoid waste , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

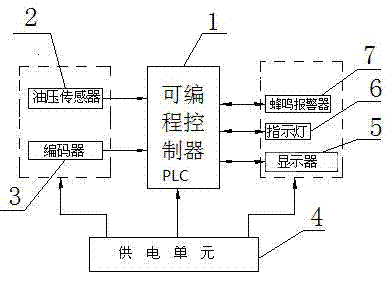

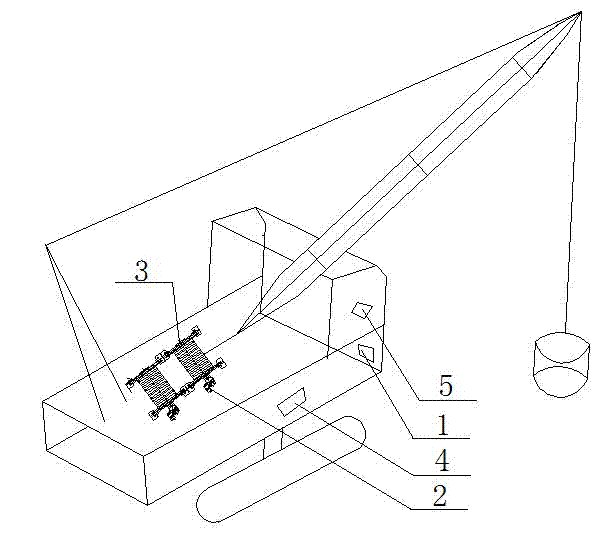

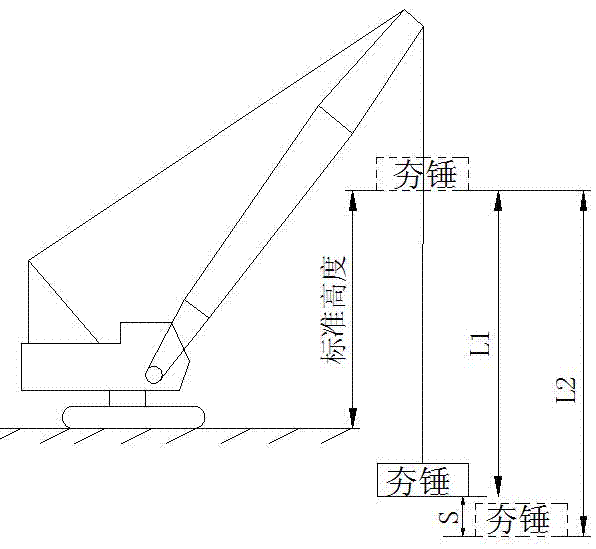

[0035] as attached Figure 1-4 Said, a dynamic tamping machine tamping weight detection system, based on the dynamic tamping machine; this system includes: programming controller PLC1, oil pressure sensor 2, encoder 3 and display 5; said programming controller PLC1 input terminal It is connected with the oil pressure sensor 2 and the encoder 3, and the output end is connected with the display 5; the input end of the oil pressure sensor 2 is connected with the winch motor, and the output end is connected with the programming controller PLC1; the oil pressure sensor 2 will detect The pressure value is transmitted to the programming controller PLC1; the input end of the encoder 3 is connected to the winch motor, and the output end is connected to the programming controller PLC1; the encoder 3 transmits the length of the detection wire rope to the programming controller PLC1 The input terminal of the display 5 is connected with the programming controller PLC1, and the dynamic comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com