Steel-mesh separation wall

A technology of steel mesh and mesh, applied in the direction of walls, building components, buildings, etc., can solve the problems of easy falling off of horizontal bars and longitudinal bars, irregular construction and installation quality, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

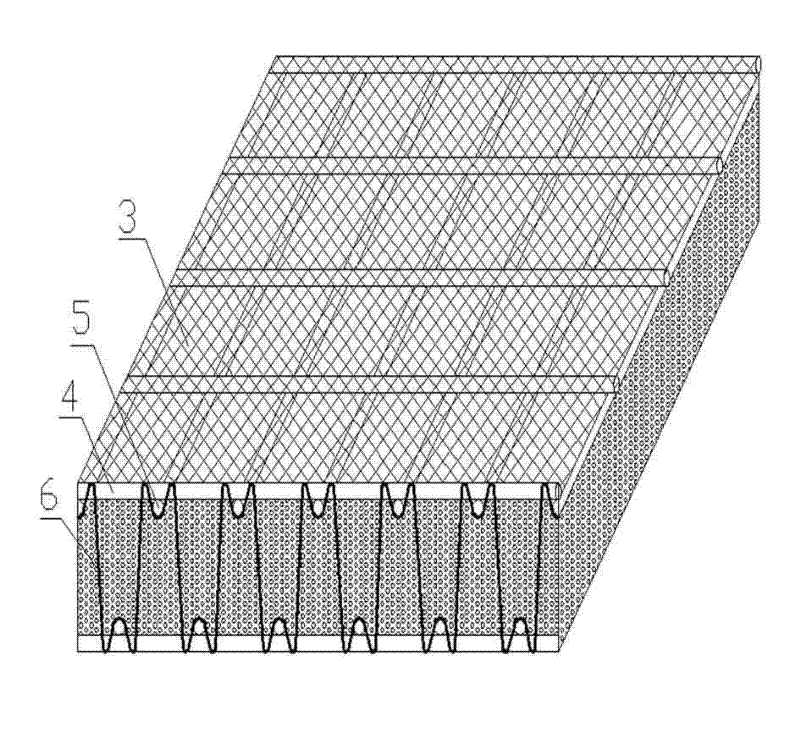

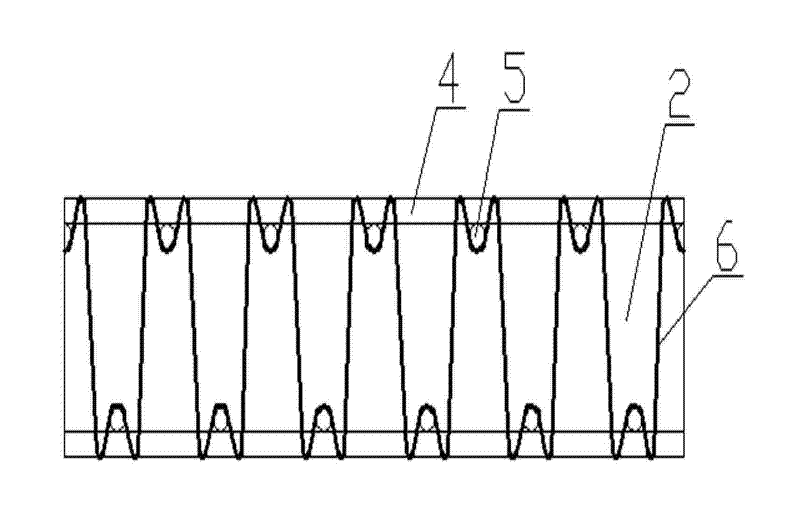

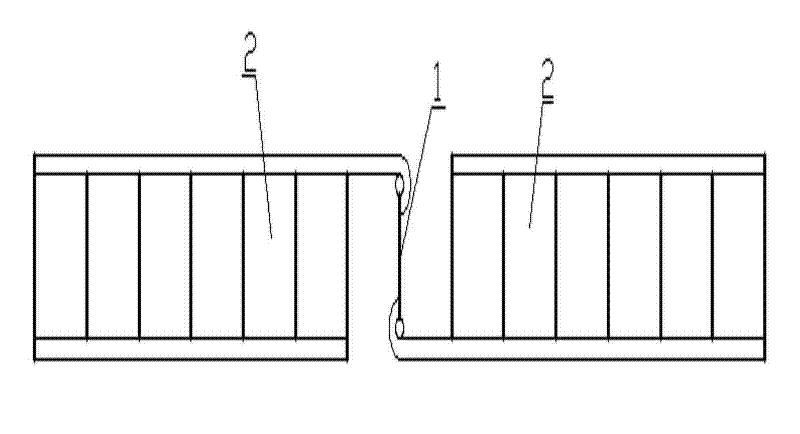

[0022] Such as figure 1 As shown, the steel mesh partition wall of the present invention is composed of a structural column 1 and one or more mesh sheets 2, and the mesh sheet 2 and the structural column 1 are connected into one body through a positioning piece 7, and the positioning piece 7 is a U Type structure, the two legs of the positioning piece 7 are inclined inward, and the horizontal angle with the positioning piece 7 is less than 90 degrees, there is a concave in the center of the positioning piece 7, and the meshes 2 are connected into one body through the structural column 1, and the steel mesh The surface 3 and the frame constitute the mesh 2, and there is foam concrete in the middle of the mesh 2, the steel mesh surface 3 is located on the outer surface of the frame, the stressed gluten 4, the stressed tendon 5 and the support frame 6 form the frame, and the support frame 6 is continuous W-shaped, there is a concave at the top of the W-shaped, and the parallel st...

Embodiment 2

[0024] A method for installing a steel mesh partition wall as described in Embodiment 1, the steps are as follows:

[0025] a. Use the steel bar welding machine to make the steel bar into the mesh;

[0026] b. The structural column, the mesh and the mesh are fixed with a positioning piece;

[0027] c. Use a grouting machine to inject concrete into the structural column, and fill it up after vibration;

[0028] d. After the wall is filled, use a spraying machine to spray, paint and smooth the whole wall. After at least 4 to 5 days of self-drying, use a grouting machine to inject foam concrete into the hollow of the mesh;

[0029] e. After foaming, it becomes porous, and the installation is completed after solidification and molding.

[0030] The foam concrete is any one of polyurethane foam, polystyrene foam, aerated concrete and fiber concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com