Horizontal type environmentally-friendly boiler

A boiler and environmental protection technology, applied in steam boilers, water-tube steam boilers, blasting equipment, etc., can solve the problems of inability to clean up dust, low combustion value, large heat loss, etc., to achieve safe and reliable water circulation, safe and reliable use, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

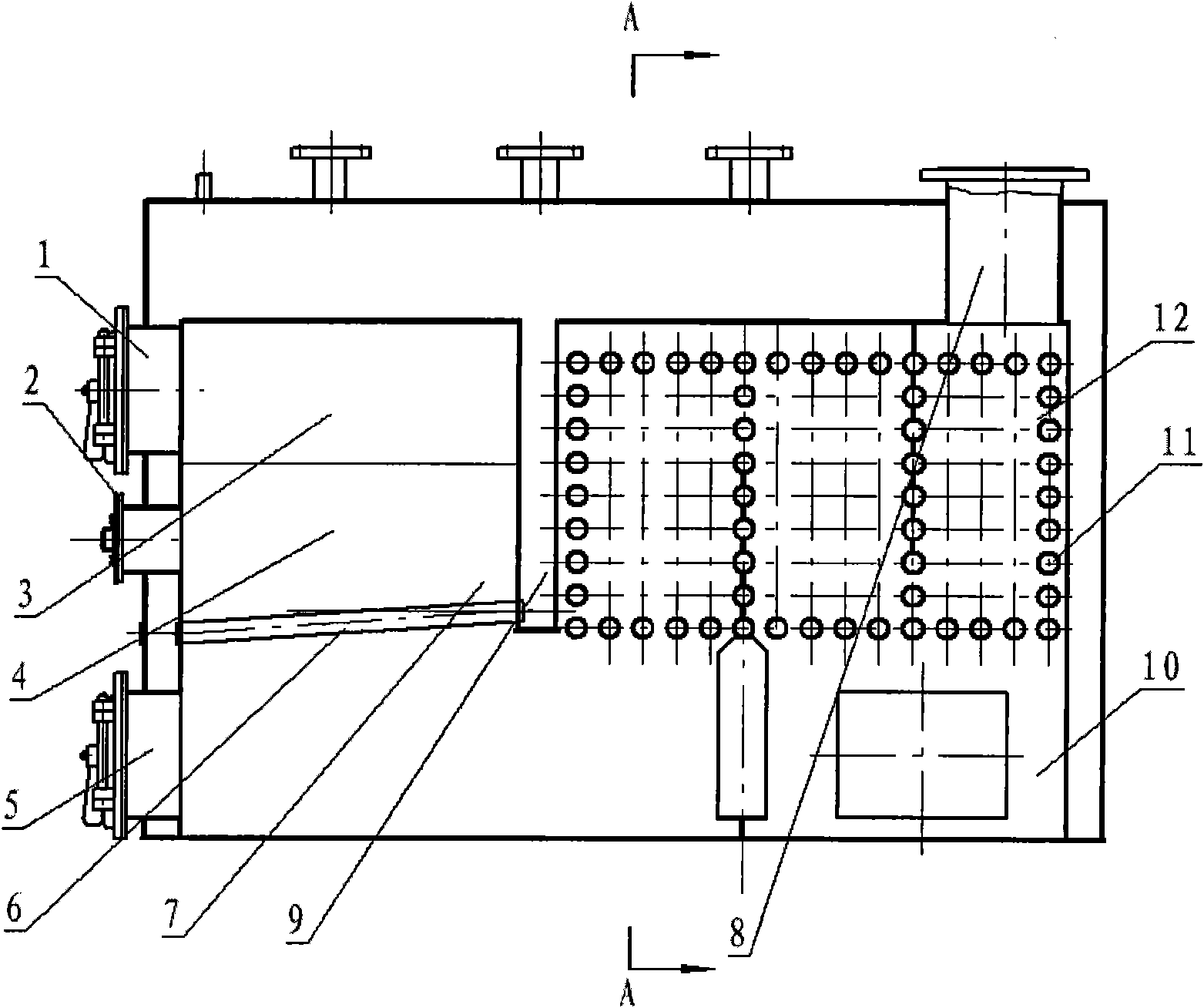

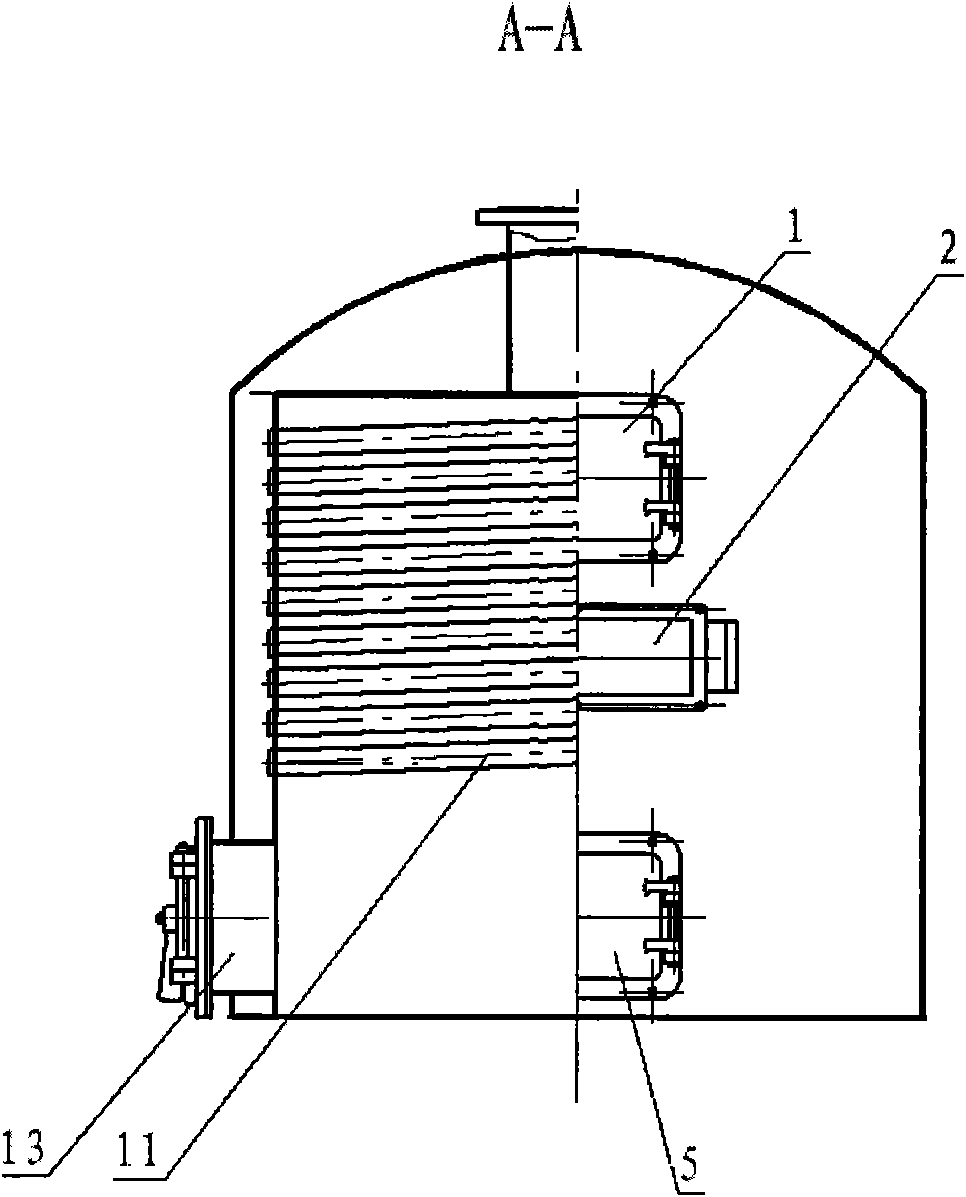

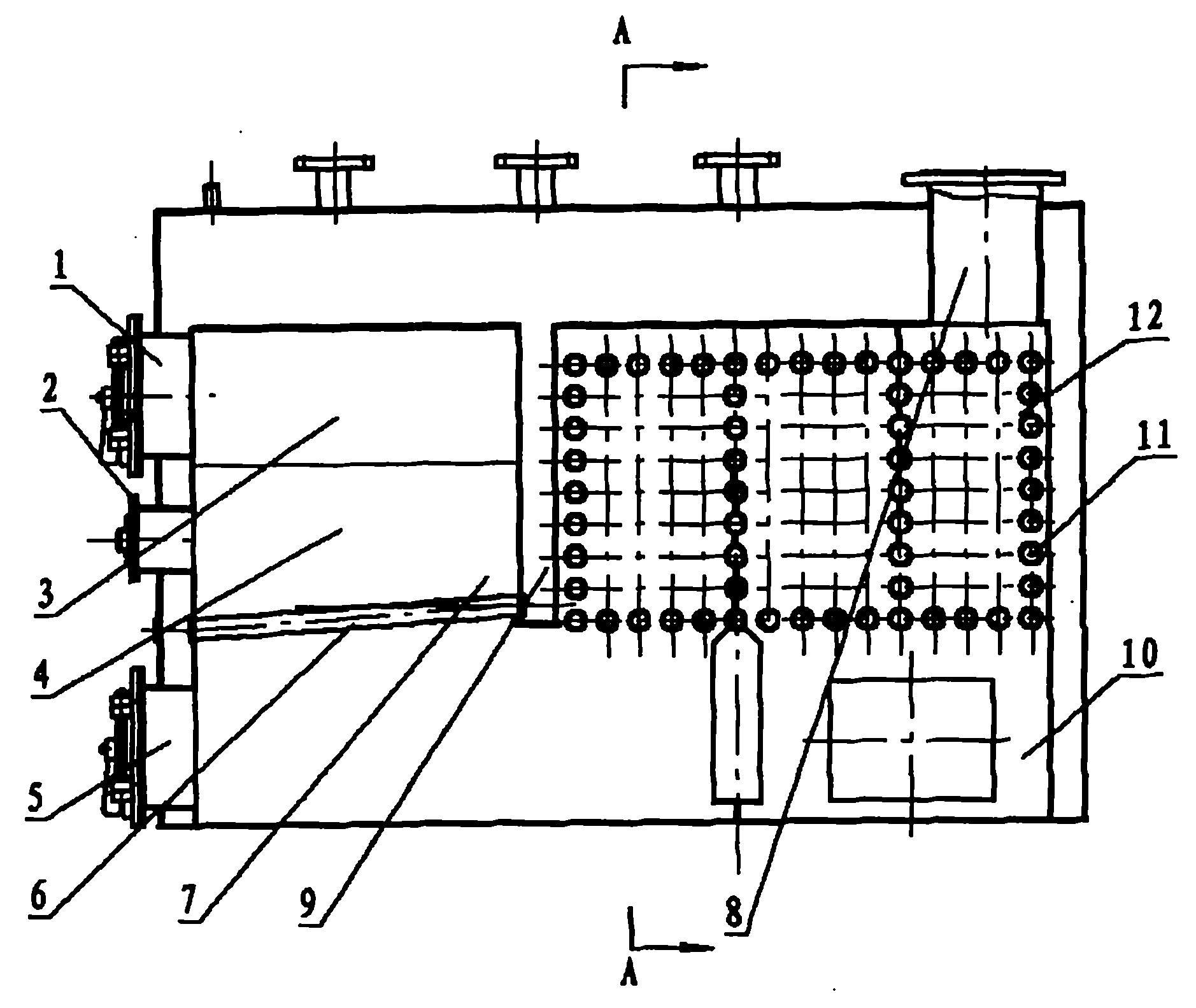

[0017] Such as figure 1 , figure 2 Shown: a horizontal environmentally friendly boiler, the boiler includes a smoke exhaust port 8 on the top of the furnace, a dust removal door 13 is provided on one side of the furnace, a furnace door 1 and a furnace door 2 are provided on the front side of the furnace, and the furnace is divided into a front part The two spaces of the combustion zone and the rear convection tube bundle zone are separated by a water-cooled partition wall 9 and communicated at the opening below the partition wall; The combustion chamber 7 is formed above the row 6; the convection tube bundle area includes a convection tube bundle 11 composed of inclined water pipes, a dust accumulation chamber 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com