High pressure digestion ICP-MS method for determining rare earth element content in crude oil

A technology of ICP-MS and ICP-OES, which is applied in the direction of measuring devices, preparation of test samples, material analysis through electromagnetic means, etc., can solve problems such as lack of accuracy and affect the determination results of ICP-MS method, and achieve improvement The effect of the digestion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

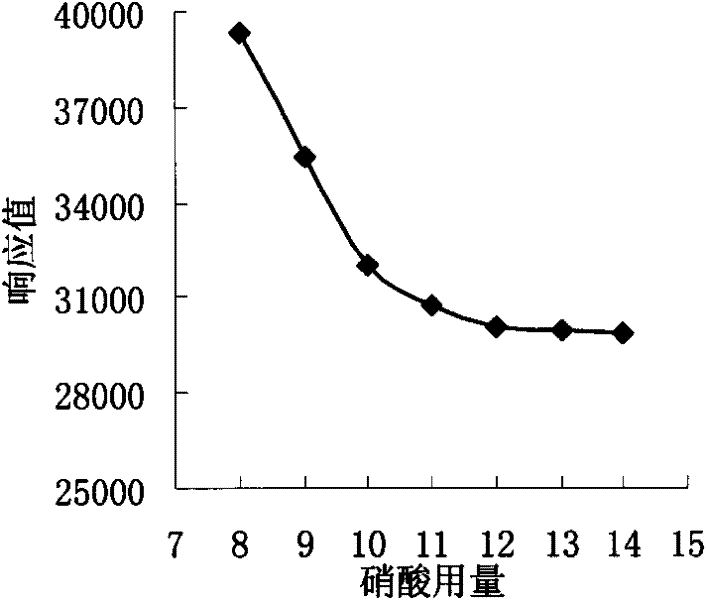

[0091] Weigh 0.4012g of Dopa crude oil sample and place it in a 100mL high-pressure digestion tank, add 2mL of hydrogen peroxide with a concentration of 30%, then add 12mL of nitric acid with a concentration of 709%, tighten the lid of the tank, put it in a blast drying oven, and heat up to 195°C Keep the temperature for another 5 hours, then turn off the power and let it cool down naturally. After digestion, open the lid of the tank, place the sample solution in a fume hood and let it stand until the sample solution is clear, then transfer it to a 25mL plastic volumetric flask, and dilute to 25mL with ultrapure water to obtain a sample digestion solution. The digestion solution obtained above was measured with an inductively coupled plasma spectrometer, that is, an ICP-OES instrument, to measure the spectral intensity of carbon contained in the digestion solution at 193.027nm, and the measured carbon intensity value was 32108.

[0092] Use the ICP-MS method to quickly determi...

Embodiment 3

[0105] Weigh 0.4086g of the Escalante crude oil sample and place it in a 100mL high-pressure digestion tank, add 2mL of hydrogen peroxide with a concentration of 30%, then add 12mL of nitric acid with a concentration of 70%, tighten the lid of the tank, put it in a blast drying oven, and heat up to Keep the temperature at 195°C for another 5 hours, then turn off the power and let it cool down naturally. After digestion, open the lid of the tank, place the sample solution in a fume hood and let it stand until the sample solution is clear, then transfer it to a 25mL plastic volumetric flask, and dilute to 25mL with ultrapure water to obtain a digestion solution. The digestion solution obtained above was measured with an inductively coupled plasma spectrometer, that is, an ICP-OES instrument, to measure the spectral intensity of carbon contained in the digestion solution at 193.027nm, and the measured carbon intensity value was 33158.

[0106] Use the ICP-MS method to quickly det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com