Frequency conversion method of non-ferrous metal electromagnetic stirrer and frequency conversion device for realizing frequency conversion method

An electromagnetic stirrer and non-ferrous metal technology, which is applied to stirring devices, output power conversion devices, electrical components, etc., can solve problems such as poor adaptability, poor consistency of frequency conversion output waveforms, and non-ferrous metal electromagnetic stirrers. Efficiency and quality, good output waveform consistency, and the effect of improving self-protection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

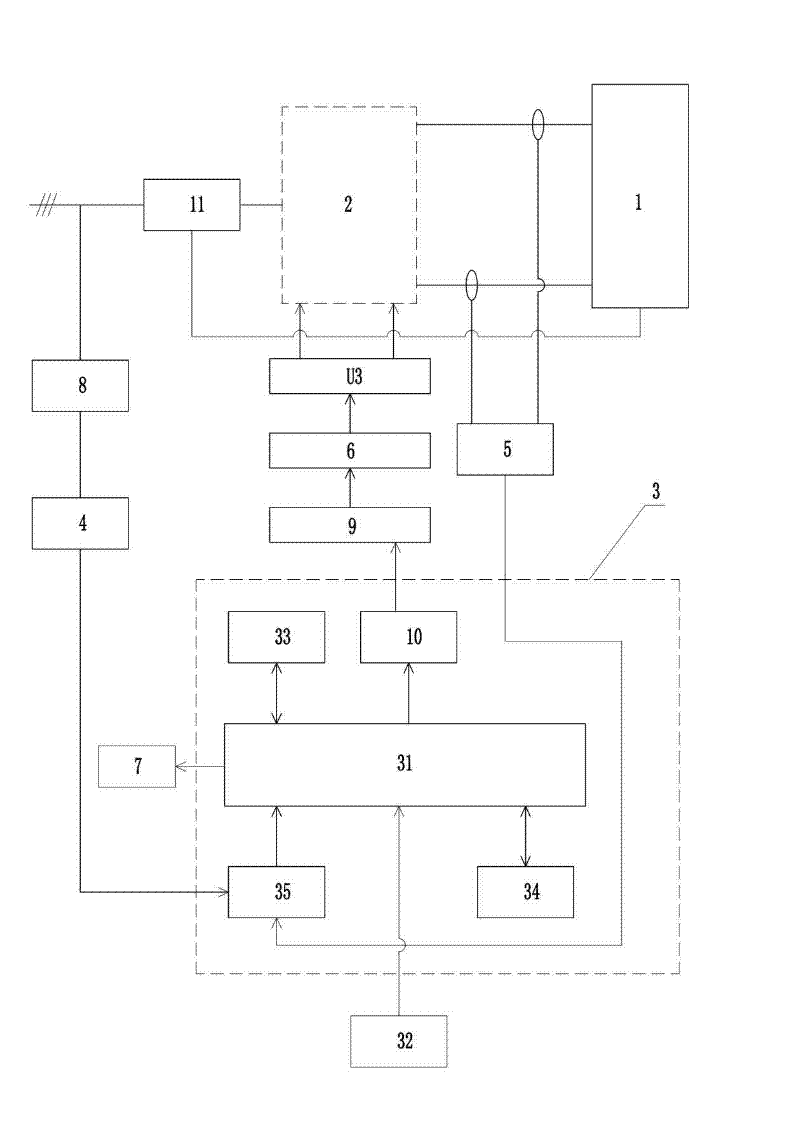

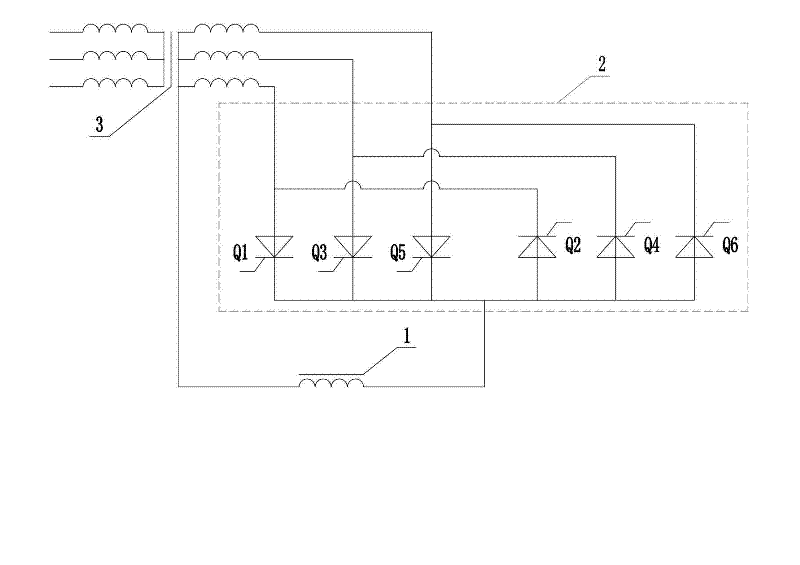

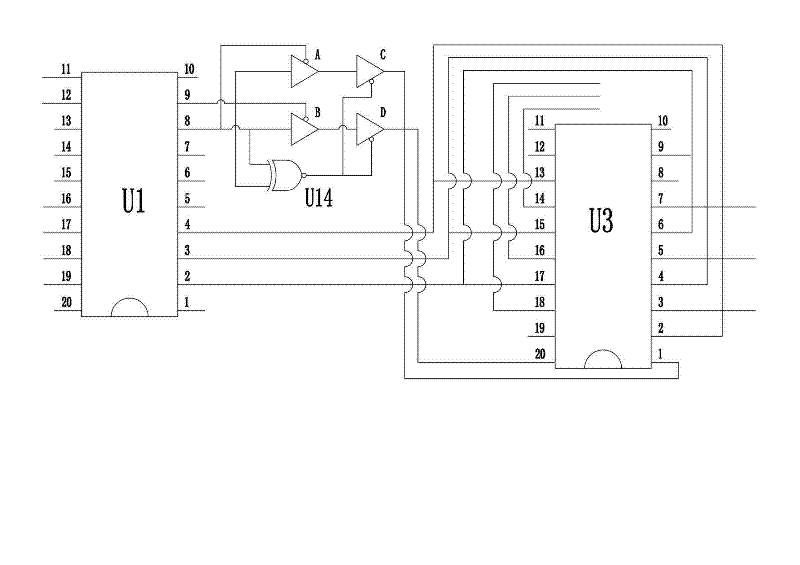

[0036] like figure 1 As shown, the frequency conversion device includes an inverter group 2 whose output end is electrically connected to the electromagnetic stirrer 1, and the input end of the inverter group 2 is electrically connected to an AC power supply through an isolation transformer. like figure 2 As shown, the inverter group 2 includes a group of conduction bridges, and the conduction bridge includes a forward conduction group and a reverse conduction group electrically connected to the AC power supply, wherein the forward conduction group includes forward thyristors Q1, Q3, Q5 , the cathodes of the forward thyristors Q1, Q3, Q5 are electrically connected together, the reverse conduction group includes the reverse thyristors Q2, Q4, Q6, and the anodes of the reverse thyristors Q2, Q4, Q6 are electrically connected together.

[0037] The frequency conversion device also includes a controller 3 for controlling the operation of the inverter group 2 , the controller 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com