Water-proof electric heating floor system, water-proof electric heating floor and electric heating assembly thereof

An electric heating floor, waterproof technology, applied in the field of building decoration, can solve the problems such as unimplemented and unsolved waterproofing of the floor system and leakage of electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0158] (Example 1, electric heating assembly)

[0159] See Figure 7 to Figure 9 , The electric heating assembly 13 includes an electric heating sheet 13-1 and a power supply socket 13-2. The electric heater 13-1 has two sheets, and its structural shape is basically the same. The two electric heaters 13-1 are divided into a front side electric heater 13-11 and a rear side electric heater 13-12 according to their front and rear positions. The sheet 13-11 and the rear side electric heating sheet 13-12 are arranged parallel to each other. The power supply socket 13-2 is divided into a left power supply socket 13-21 and a right power supply socket 13-22 according to its left and right positions. The left end of the front side electric heater 13-11 and the rear side electric heater 13-12 are fixedly connected and electrically connected with the right side of the left power supply socket 13-21 respectively, and the front side electric heater 13-11 and the rear side electric heater...

Embodiment 2

[0171] (Example 2, electric heating assembly)

[0172] See Figure 26 and Figure 27 , the rest of this embodiment is the same as Embodiment 1, the difference is that the openings of the two socket holes 13-2-1b of the base 13-2-1 of the power supply socket part 13-2 of the electric heating assembly 13 face underside. The conductive copper sheet 13-2-2 is a substantially "T"-shaped copper sheet, wherein the middle part of the conductive copper sheet 13-2-2 in the front-to-back direction is provided with a bending portion extending outward along the left-right direction and bending upward. 13-2-21, the front and rear ends of the conductive copper sheet 13-2-2 are provided with welding holes through the up and down direction, and the parts of the welding holes are welded and fixed on the corresponding electric heating sheet 13-1 with solder joints 13- 1-4 on the electrode copper skin 13-1-2. The copper pin 13-2-3 is fixed by riveting and electrically connected to the outer ...

Embodiment 3

[0173] (Example 3, waterproof electric heating floor)

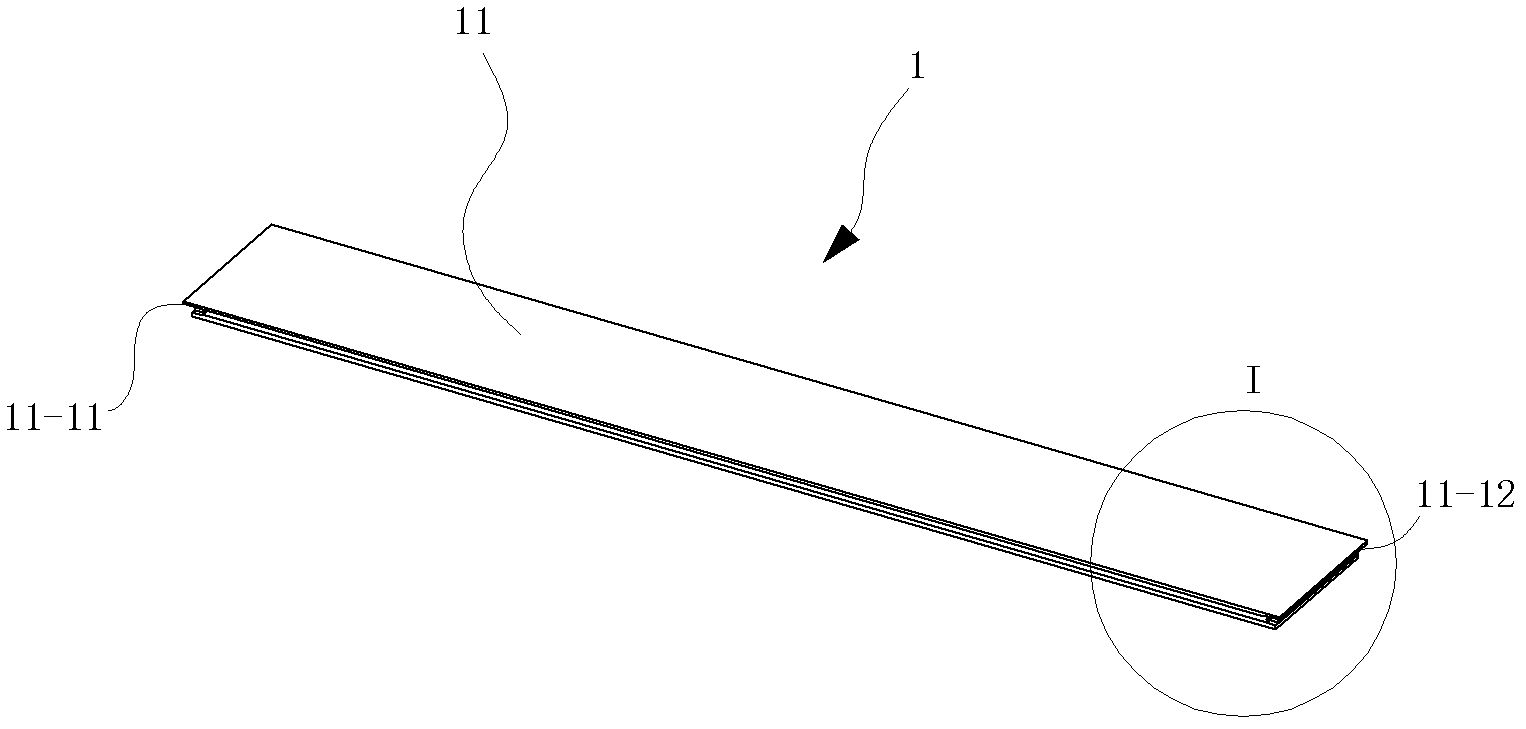

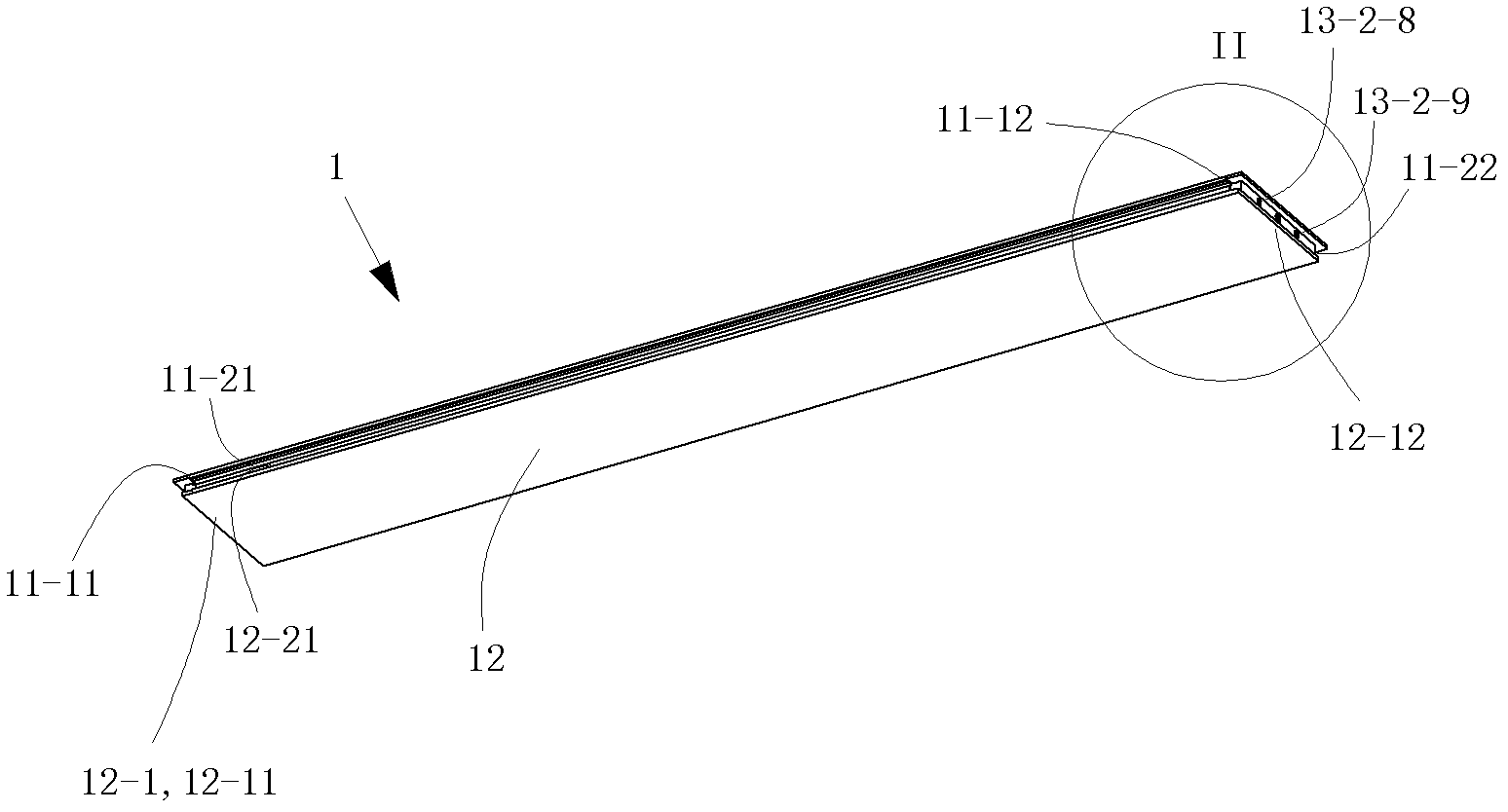

[0174] See Figure 1 to Figure 4 and Figure 6 , The waterproof electric heating floor 1 of this embodiment includes an upper body 11, a bottom plate 12 and an electric heating assembly. The electric heating assembly adopts the electric heating assembly 13 described in Embodiment 1.

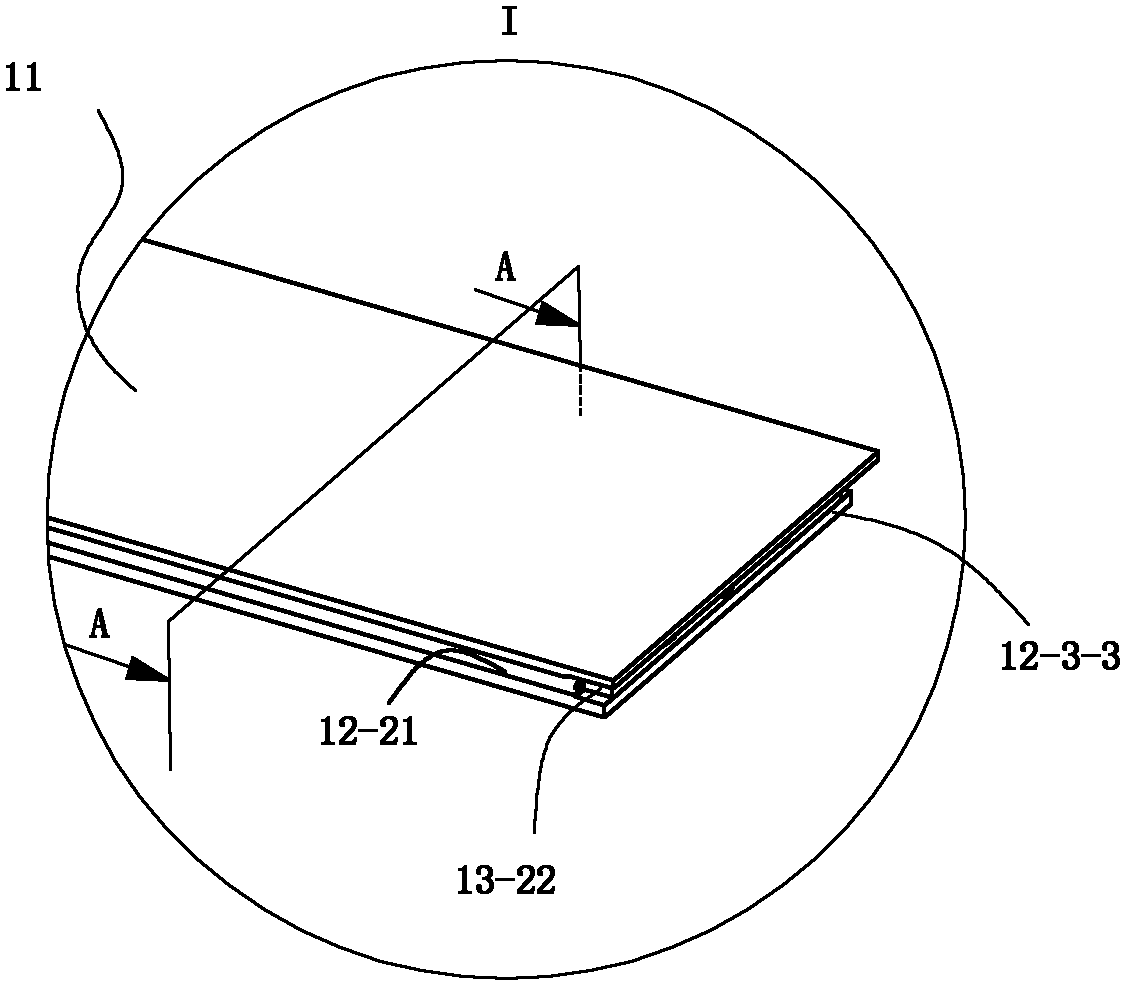

[0175] See figure 1 , image 3 and Figure 10 , The upper body 11 is an integral piece made of wood material. The basic shape of the upper body 11 is a plate-shaped rectangular parallelepiped, and the left and right sides of the upper body 11 are the insertion shielding parts 11-1 formed by cutting the lower part, and the front and rear sides of the upper body 11 are formed by cutting the lower part. The formed locking part 11-2.

[0176] See Figure 10 , the two insertion shielding parts 11-1 of the upper body 11 are divided into a left insertion shielding part 11-11 and a right insertion shielding part 11-12 according to their lef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com