Large-scale anti-corrosion agitating paddle and preparation method thereof

An anti-corrosion and stirring paddle technology, applied in the field of stirring paddles, can solve the problems of long maintenance period, short service time and short service life, and achieve the effect of increasing overall strength, reducing mechanical wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

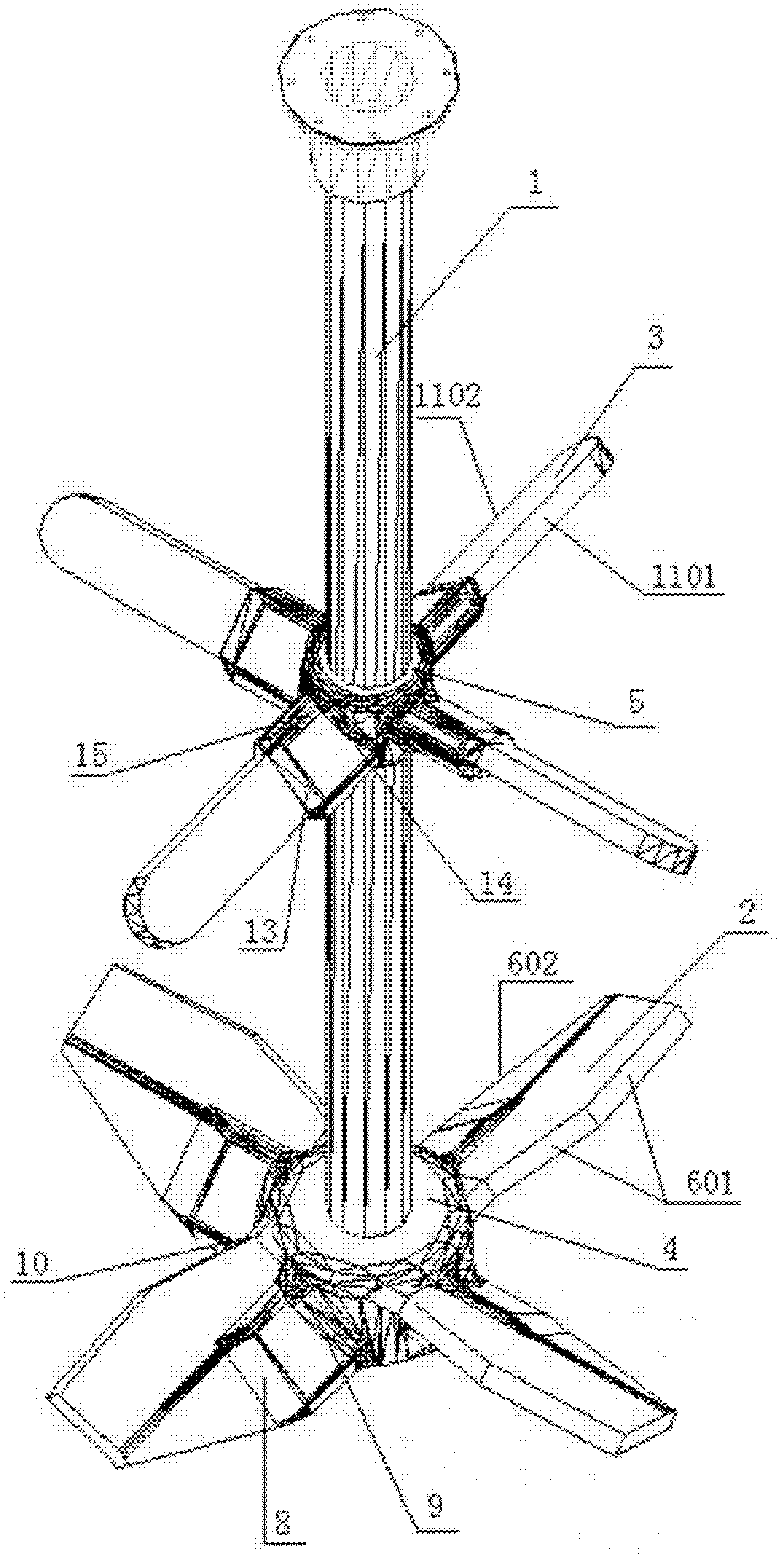

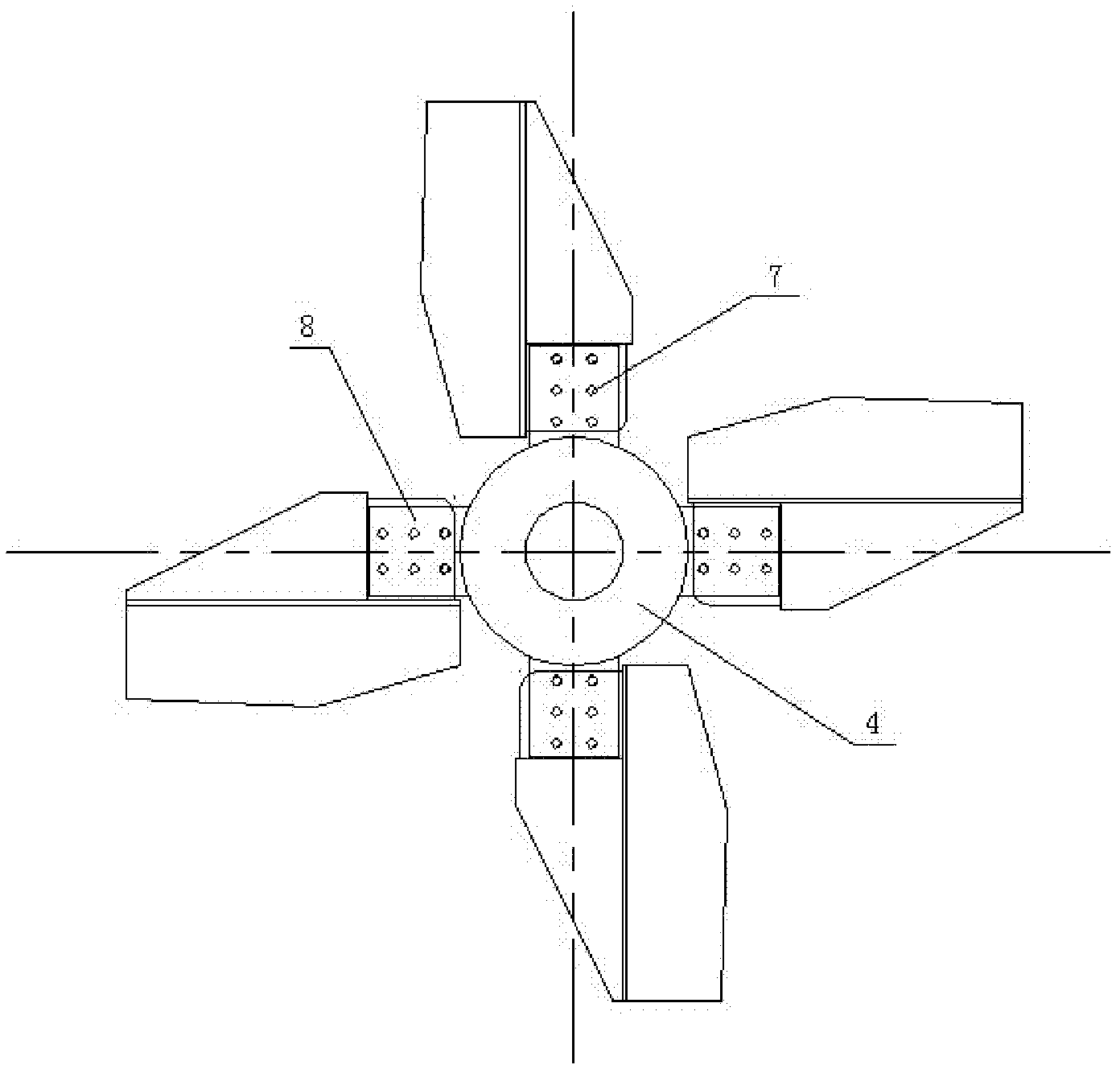

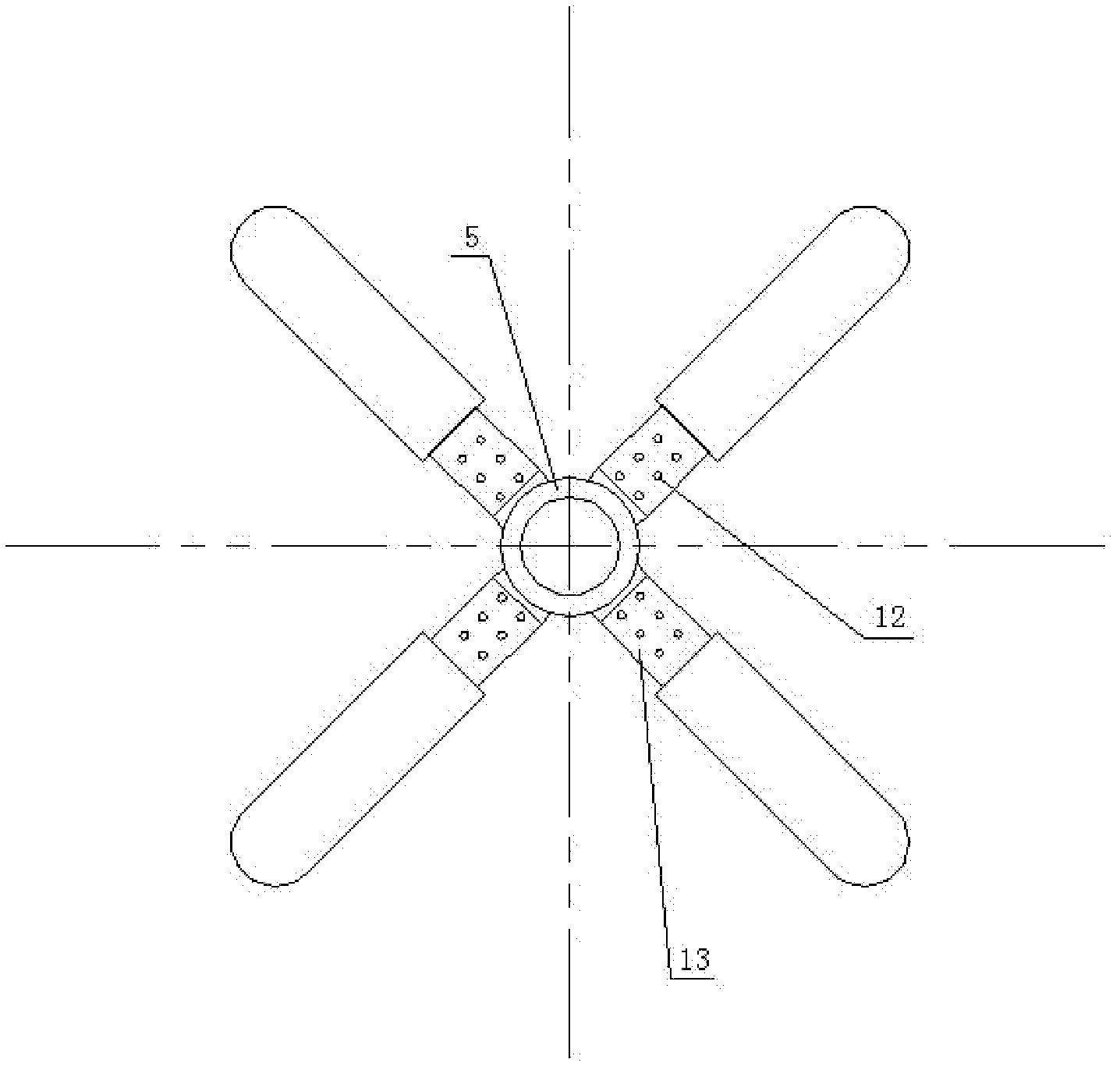

[0045] see figure 1 , the present embodiment is a double-layer eight-blade stirring paddle, which includes a stirring shaft 1, a curved paddle 2 and a straight paddle 3, a hub 4 and a hub 5, and the curved paddle 2 and the straight paddle 3 are formed by the internal Based on the blade-shaped steel skeleton and the anti-corrosion material formed by wrapping the steel skeleton. It can be seen from the figure that the double-layer eight-blade agitator is equipped with a four-bladed arc-shaped paddle 2 through the hub 4 on the bottom layer of the agitating shaft 1, and a four-bladed straight paddle 3 is installed on the upper layer of the agitating shaft 1 through the hub 5.

[0046] The blade thickness of the arc-shaped blade 2 in this embodiment is 70mm, and the upper and lower surfaces of the blade are respectively convex and concave arc surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com