A kind of preparation method of ceramic bulletproof plate

A technology of bulletproof plates and ceramics, which is applied in protective equipment, ceramic molding machines, offensive equipment, etc., and can solve the problems of difficult gaps in ceramic sheets, poor resistance to continuous blows, and short curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

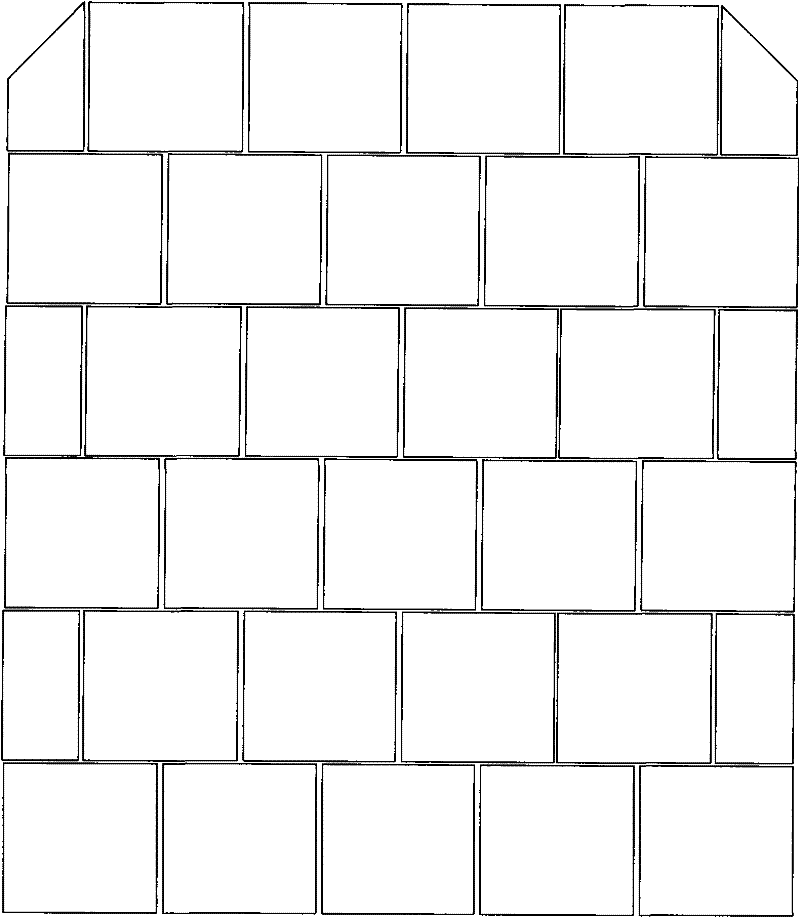

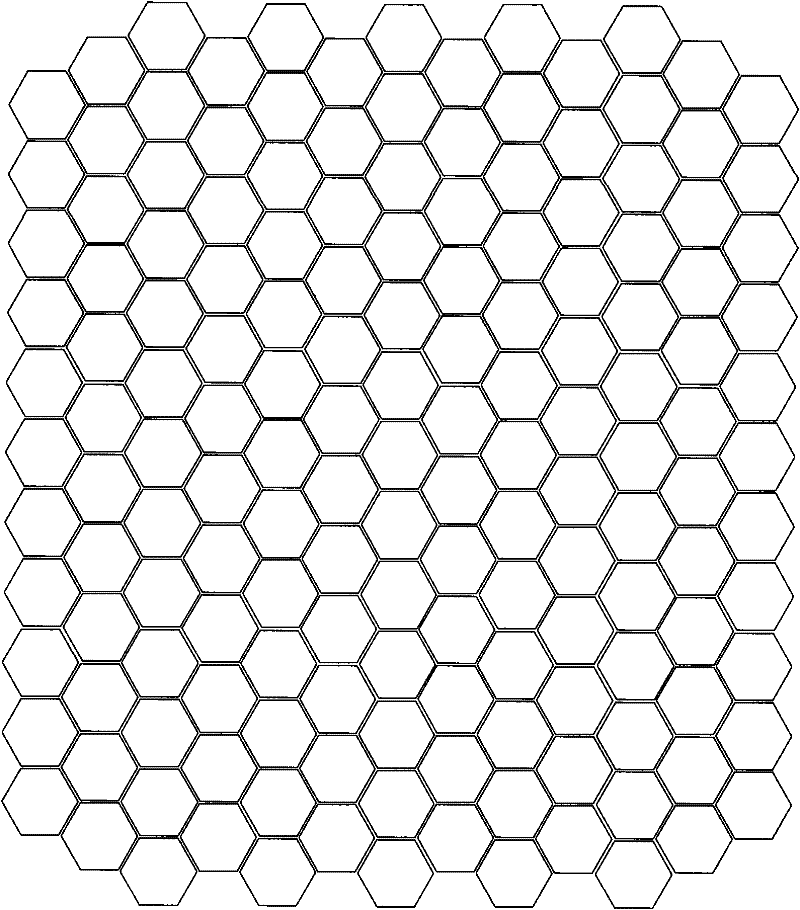

Image

Examples

example 1

[0022] Aluminum oxide and ultra-high molecular weight polyethylene woven laminates are used to make ceramic bullet-proof panels, which can protect against M80 lead-core bullets required by NIJ III. The surface density of the bullet-proof panels is 30kg / m 2 , see Table 1 for specific bullet rate of fire and simulated torso depression.

[0023] Table 1 Live-fire test data of alumina ceramic bullet-proof plate

[0024] firing order

example 2

[0026] The ceramic bullet-proof board is made of silicon carbide and ultra-high molecular weight polyethylene woven laminated board, which can protect the M80 lead-core bullets required by NIJ III level, and the surface density of the bullet-proof board is 26kg / m 2 , see Table 2 for specific bullet rate of fire and simulated torso depression.

[0027] Table 2 Live-fire test data of silicon carbide ceramic bullet-proof plate

[0028] firing order

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com