High-speed UV light curing control device for printing press

A printing machine and control device technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of inconvenience, current impact damage to UV lamps, etc., to improve economic benefits, ensure normal work, and avoid shocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

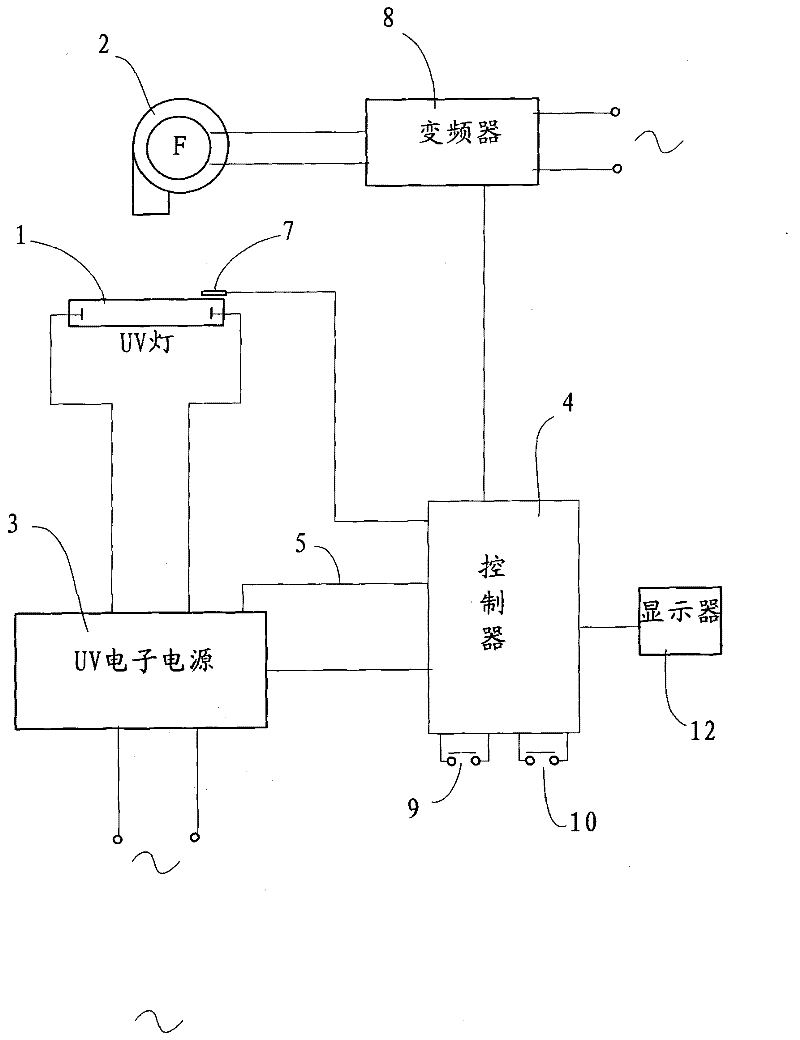

[0025] see figure 1 As shown, the high-speed UV photocuring control device for a printing machine in a preferred embodiment of the present invention includes a UV lamp 1 with a condenser, a fan 2, a UV electronic power supply 3 with a fault detection signal line 5, and a controller 4, wherein The output terminal of the UV electronic power supply is connected to the UV lamp 1, and its fault detection signal line 5 is connected to the controller 4; a temperature sensor 7 is arranged in the illumination area of the UV lamp 1, and the temperature sensor 7 is electrically connected to The controller 4 is provided with a frequency converter 8, the output terminal of the frequency converter 8 is connected to the fan 2, the input control terminal of the frequency converter 8 is connected to the controller 4, and the input terminal of the controller 4 A start button 9 and a power reduction button 10 are provided, and the output terminals of the controller 4 are respectively connected...

Embodiment 2

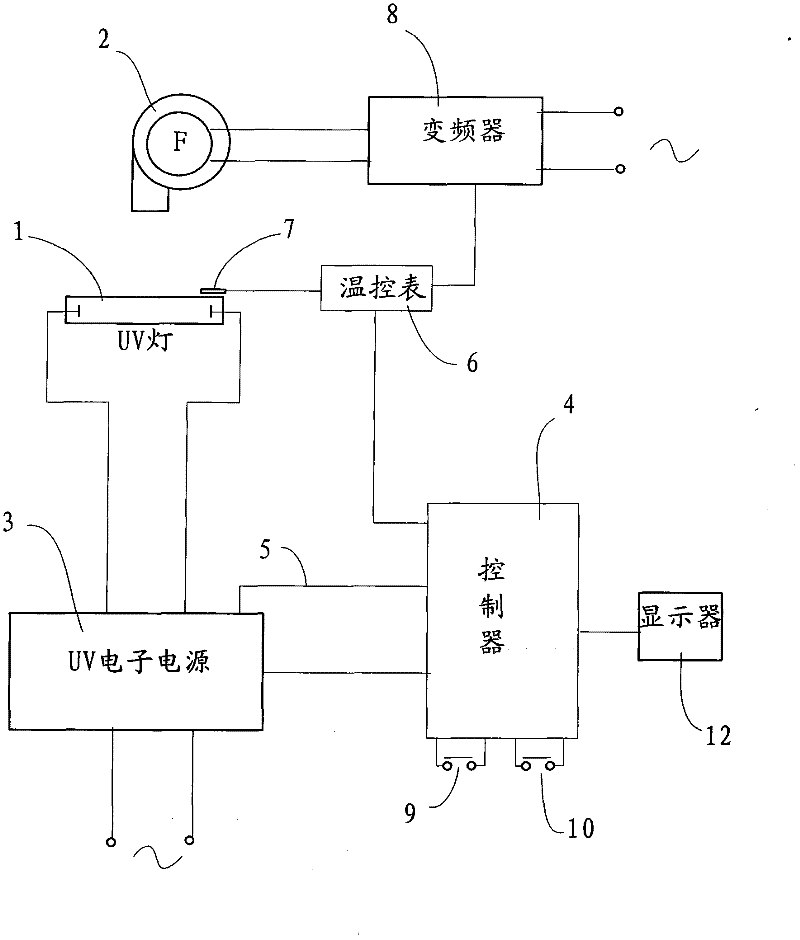

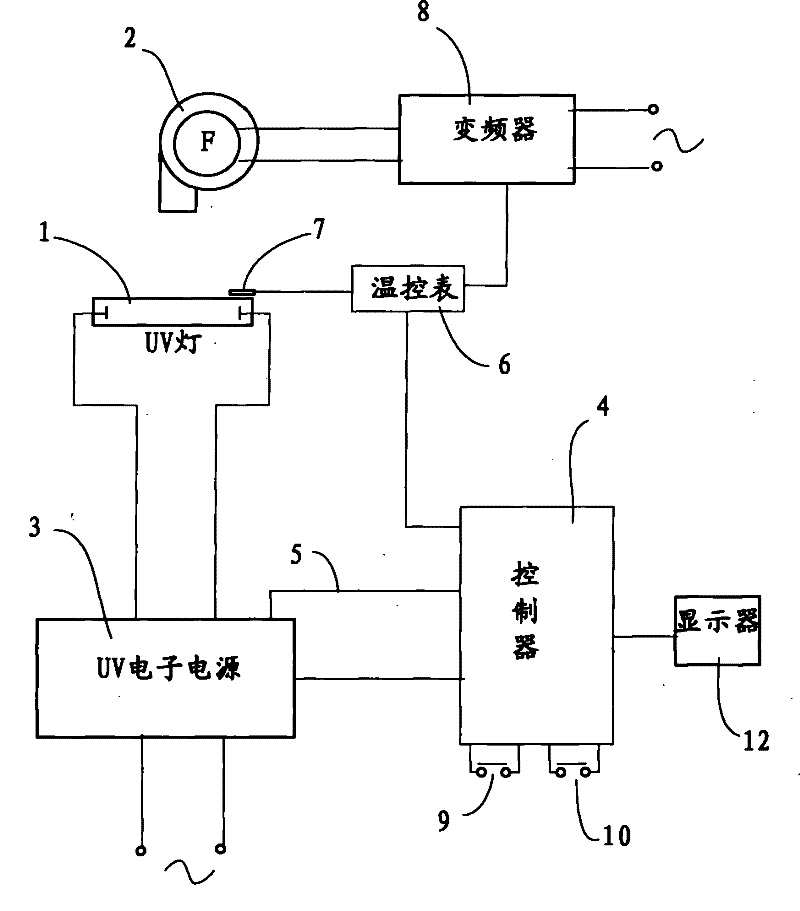

[0032] see figure 2 As shown, the high-speed UV photocuring control device for printing presses in another preferred embodiment of the present invention includes a UV lamp 1 with a condenser, a fan 2, a UV electronic power supply 3 with a fault detection signal line 5, and a controller 4 , wherein a frequency converter 8 and a temperature controller 6 are provided, the output terminal of the UV electronic power supply 3 is connected to the UV lamp 1, and its fault detection signal line 5 is connected to the controller 4; the illumination area of the UV lamp 1 There is a temperature sensor 7 inside, the temperature sensor 7 is electrically connected to the thermostat 6, the output of the thermostat 6 is respectively connected to the controller 4 and the frequency converter 8, and the output of the frequency converter 8 The terminal is connected to the fan 2 , the input of the controller 4 is provided with a start button 9 and a power reduction button 10 , and the output of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com