A treatment method for heavy metal-containing wastewater

A treatment method and technology for heavy metals, applied in the field of water treatment, can solve the problems that the pH value cannot meet the requirements of precipitation or effluent, the heavy metal ions or suspended solids do not meet the standard, and the precipitation effect is not good. The effect of eliminating cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

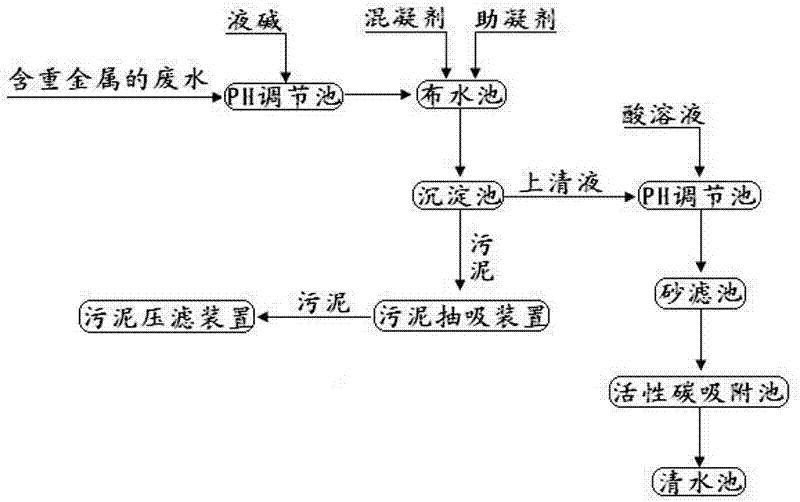

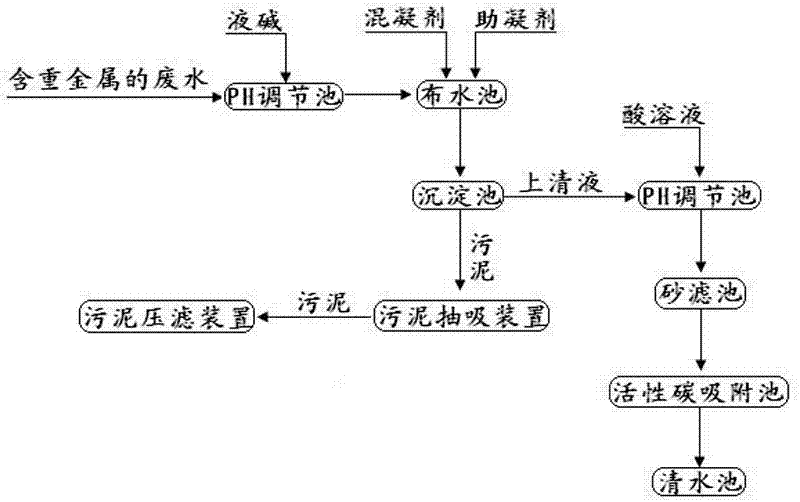

[0023] Such as figure 1 As shown, first lead-containing wastewater with a pH value of about 1 is introduced into the pH adjustment tank, and at the same time, a certain amount of liquid caustic soda with a concentration of 35% is added into the pH-adjusted pool. 1:100-120, adjust the PH value of lead-containing wastewater to 10.5-11 after chemical reaction; then import the lead-containing wastewater after pH adjustment into the distribution pool, and add coagulant and coagulation aid in the distribution pool In order to strengthen the sedimentation effect, the lead-containing wastewater in the water distribution pool flows into the sedimentation tank for coagulation and sedimentation under the action of gravity, and the supernatant after coagulation and sedimentation overflows from the weir on the upper side of the sedimentation tank. The mud falls into the sludge area on the bottom side of the settling tank, and is exported from the sludge outlet on the bottom side of the set...

Embodiment 2

[0025] Such as figure 1 As shown, first lead-containing wastewater with a pH value of 1 is introduced into the pH adjustment tank, and at the same time, a certain amount of liquid caustic soda with a concentration of 20% is added into the pH adjustment tank. :55-65, after the chemical reaction, the pH value of the lead-containing waste water is adjusted to 10-10.5; then the lead-containing waste water after the pH value adjustment is introduced into the distribution pool, and coagulant and coagulant are added in the distribution pool In order to enhance the sedimentation effect, the lead-containing wastewater in the water distribution tank flows into the sedimentation tank under the action of gravity for coagulation and sedimentation, and the supernatant after coagulation and sedimentation overflows from the weir on the upper side of the sedimentation tank, and the sludge obtained by sedimentation at the same time It falls into the sludge area on the bottom side of the sedimen...

Embodiment 3

[0027] Such as figure 1 As shown, first lead-containing wastewater with a pH value of 2 is introduced into the pH adjustment tank, and at the same time, a certain amount of liquid caustic soda with a concentration of 30% is added into the pH adjustment tank. :800-970, after the chemical reaction, the pH value of the lead-containing wastewater is adjusted to 9-10.5; then the lead-containing wastewater after the pH value adjustment is introduced into the distribution pool, and coagulant and coagulant are added in the distribution pool In order to enhance the sedimentation effect, the lead-containing wastewater in the water distribution tank flows into the sedimentation tank under the action of gravity for coagulation and sedimentation, and the supernatant after coagulation and sedimentation overflows from the weir on the upper side of the sedimentation tank, and the sludge obtained by sedimentation at the same time It falls into the sludge area on the bottom side of the sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com