A method for preparing multi-component copolymerized di-acid water purifying agent from aluminum alloy sludge

A technology of co-polymerizing bis-acid and aluminum alloy, which is applied in the direction of water/sludge/sewage treatment, sludge treatment, water/sewage treatment, etc., can solve the problems of undiscovered technology, etc., and achieve reduction of consumption, increase of treatment capacity and removal rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

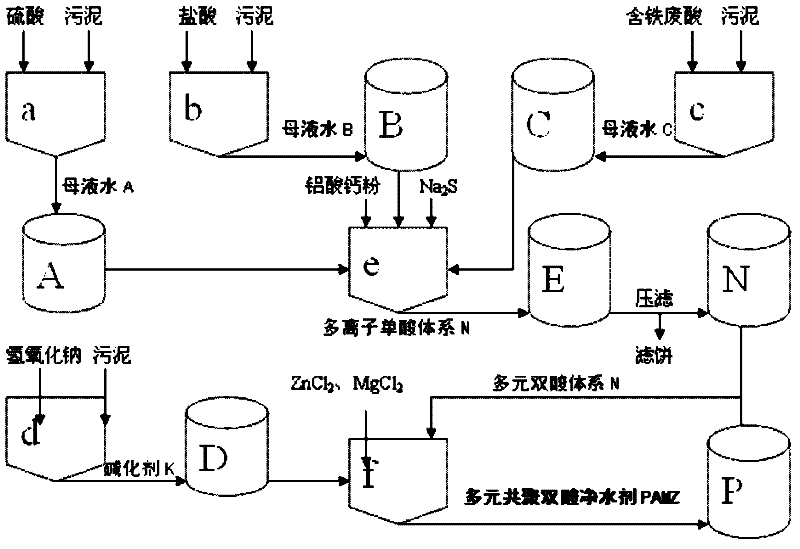

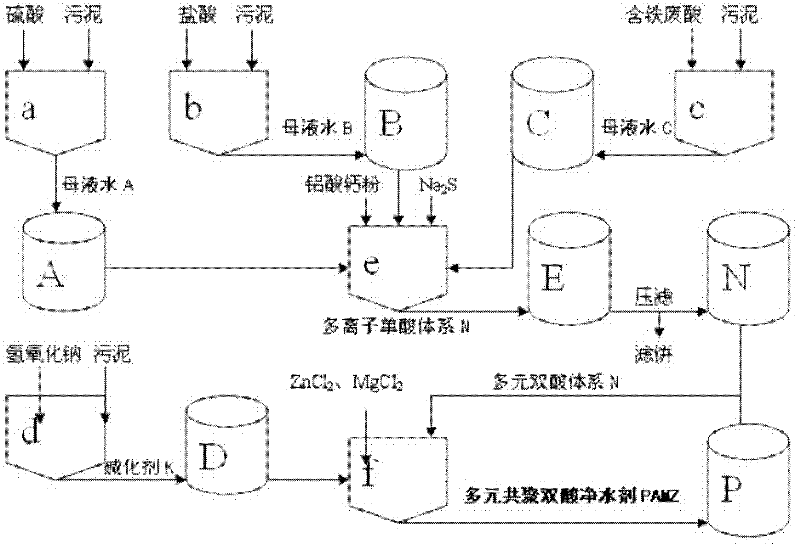

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of method of utilizing aluminum alloy sludge to prepare multi-component copolymerized di-acid water purifying agent, the steps are as follows: its formula ratio is calculated by weight parts:

[0032] (1) Preparation of mother liquor A: Add 20 parts of sulfuric acid with a mass concentration of 96% in reactor a, add 80 parts of sludge and stir for 2 hours to dissolve the sludge completely, generate mother liquor A, and store it in storage tank A .

[0033] (2) Preparation of mother liquor B: Add 50 parts of hydrochloric acid with a mass concentration of 30% in reaction kettle b, then add 70 parts of sludge and stir for 2 hours to completely dissolve the sludge to generate mother liquor B, which is stored in storage tank B .

[0034] (3) Preparation of mother liquor C: Add 30 parts of iron-containing waste acid with a mass concentration of 10% in reaction kettle c, then add 60 parts of sludge and stir for 2 hours to completely dissolve the sludge to...

Embodiment 2

[0039] Embodiment 2: A kind of method that utilizes aluminum alloy sludge to prepare multi-component copolymerized di-acid water purifying agent, the steps are as follows: its formula ratio is calculated by parts by weight:

[0040] (1) Preparation of mother liquor A: add 25 parts of sulfuric acid with a content of 70% to reaction kettle a, then add 75 parts of sludge and stir for 1.5 hours to dissolve the sludge completely to generate mother liquor A, which is stored in storage tank A .

[0041] (2) Preparation of mother liquor B: Add 55 parts of hydrochloric acid with a content of 20% in reactor b, then add 45 parts of sludge and stir for 1.5 hours to completely dissolve the sludge to generate mother liquor B, which is stored in storage tank B .

[0042] (3) Preparation of mother liquor C: Add 35 parts of iron-containing waste acid with a mass concentration of 10% in reaction kettle c, then add 65 parts of sludge and stir for 1.5 hours to completely dissolve the sludge to g...

Embodiment 3

[0047] Embodiment 3: A kind of method that utilizes aluminum alloy sludge to prepare multi-component copolymerized di-acid water purifying agent, the steps are as follows: its formula ratio is calculated by weight parts:

[0048] (1) Preparation of mother liquor A: Add 30 parts of sulfuric acid with a content of 50% to reaction kettle a, then add 80 parts of sludge and stir for 2 hours to completely dissolve the sludge to generate mother liquor A, which is stored in storage tank A.

[0049] (2) Preparation of mother liquor B: add 60 parts of 10% hydrochloric acid into reactor b, then add 50 parts of sludge and stir for 2 hours to completely dissolve the sludge to generate mother liquor B, which is stored in storage tank B.

[0050] (3) Preparation of mother liquor C: Add 40 parts of iron-containing waste acid with a mass concentration of 10% in reaction kettle c, then add 70 parts of sludge and stir for 2 hours to completely dissolve the sludge to generate mother liquor C, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com