A kind of preparation method of fast drilling agent for drilling fluid

A drilling fluid, weight ratio technology, applied in the field of drilling fluid additives, can solve problems such as unsatisfactory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, but the present invention is not limited.

[0014] 【Example】

[0015] Put 250kg of animal oil into the reaction kettle, heat it to 180°C, add 25kg of oleic acid and 30kg of chlorinated stearic acid into the reaction kettle, stir slowly and evenly, keep it warm for 90min, and cool it naturally for 12h; then add 100kg of propyl Trimethylammonium chloride, 100kg chlorinated paraffin, 150kg mechanical oil, 50kg triethanolamine, and finally add 25kg ethylene glycol; when it is cold, it can be properly heated before feeding, and finally add an appropriate amount of water and stir well to obtain the product SAPO -1 type drilling fluid fast drilling agent.

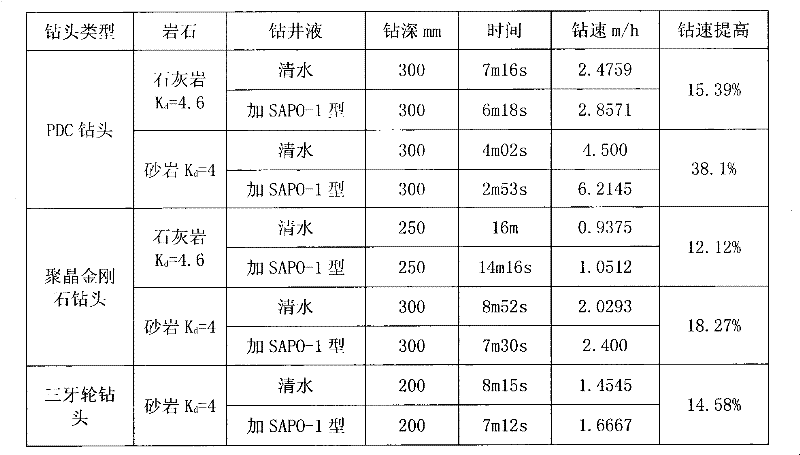

[0016] Using the drilling simulation experiment device of the Jet Fluidics Research Center of the University of Petroleum, the drill bit diameter is 92mm, the drilling pressure is 13.62kN, the rotation speed is 100rpm, the bit pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com