Visual inspection system and method capable of resisting sunlight interference

A technology of visual inspection and inspection system, applied in the field of visual inspection, can solve the problems of measurement system ambient light interference, discussion of ambient light interference, changes in reflected light intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

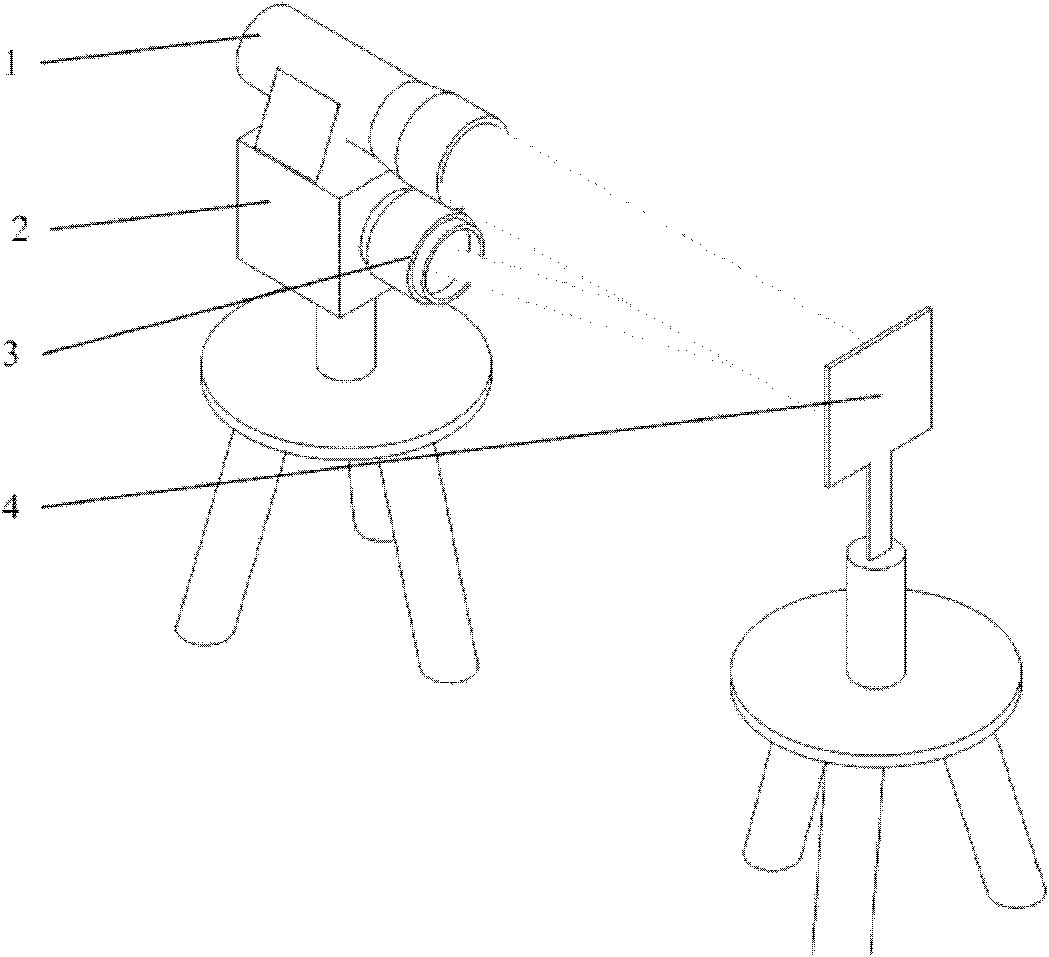

[0034] Such as figure 1 As shown, this embodiment includes: a laser 1, a camera 2, a lens 3, a reflective mark 4, a processing system 8, and an optical filter 9, wherein: the laser 1 and the camera 2 are arranged side by side at the measurement point and are close to each other. Connected to processing system 8. The reflective marker 4 is set on a certain feature point of the measured object 10 and can move together with the measured object 10 .

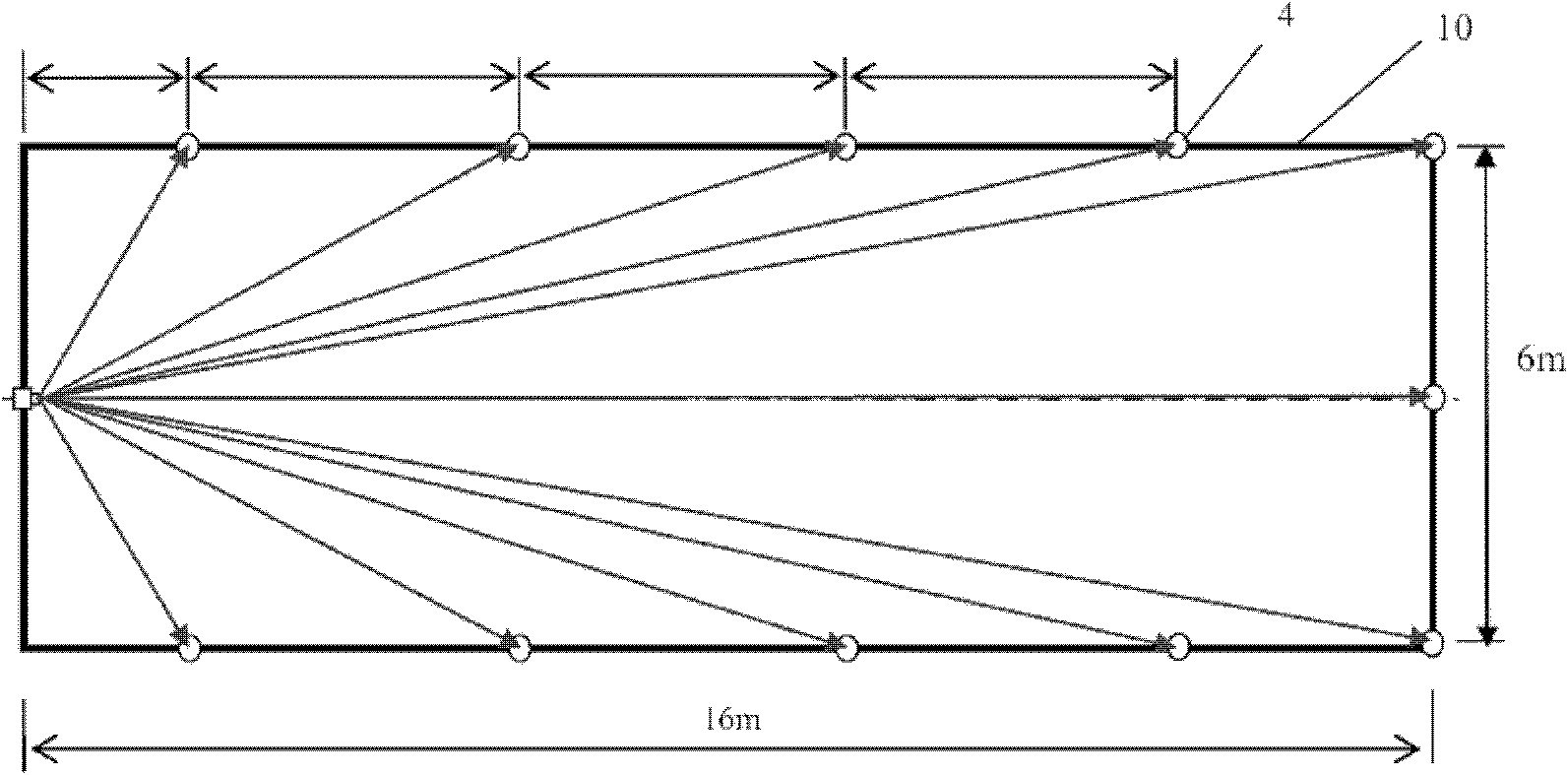

[0035] The layout of the visual inspection system is as follows figure 2 As shown, a total of 11 measurement positions are set, and a total of 11 reflective marks are arranged, which are distributed on a rectangular frame with a length of 16m and a width of 6m. The vertical deformation displacement of each mark is ±50mm.

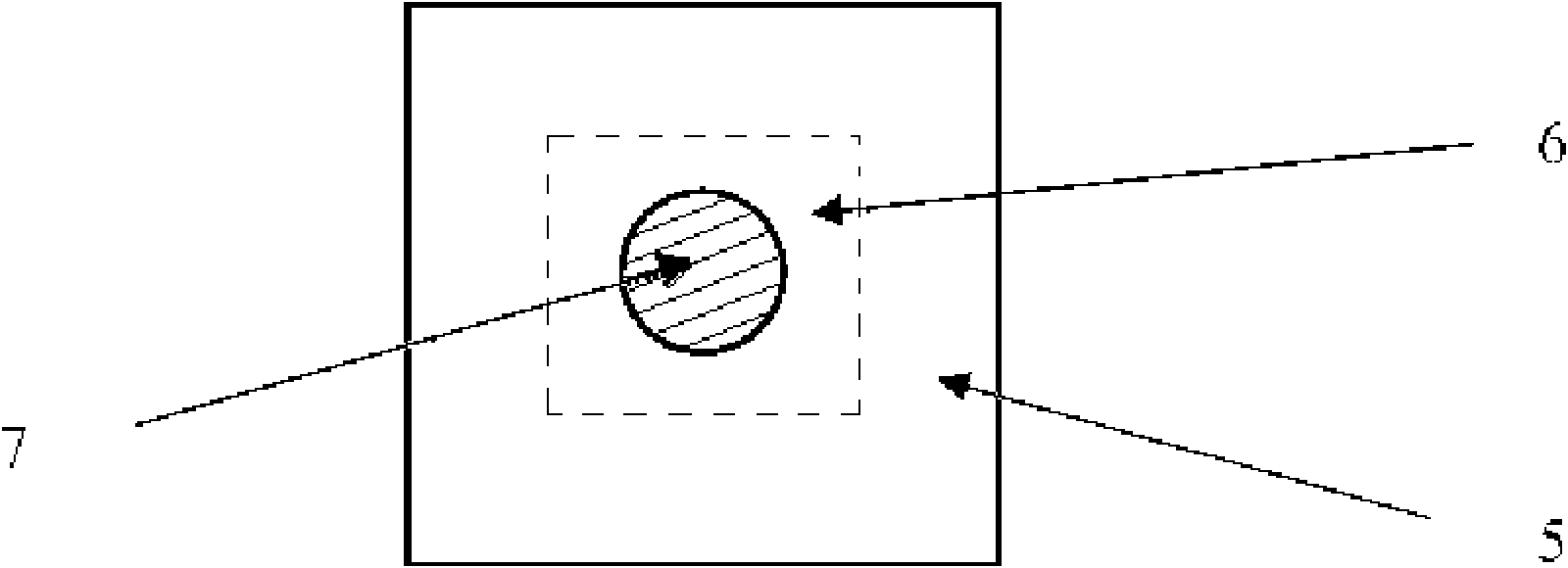

[0036] The camera 2 is a high-precision industrial area array CCD camera with a pixel of 2035×1684pixel. The lens 3 is designed and selected according to the size, distance and moving range of the measured obje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com