Optimization method of photoresist and photoresist pattern

An optimization method, photoresist technology, applied in the direction of photosensitive materials used in optomechanical equipment, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of semiconductor device defects, unclean removal, etc., and achieve the goal of improving yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

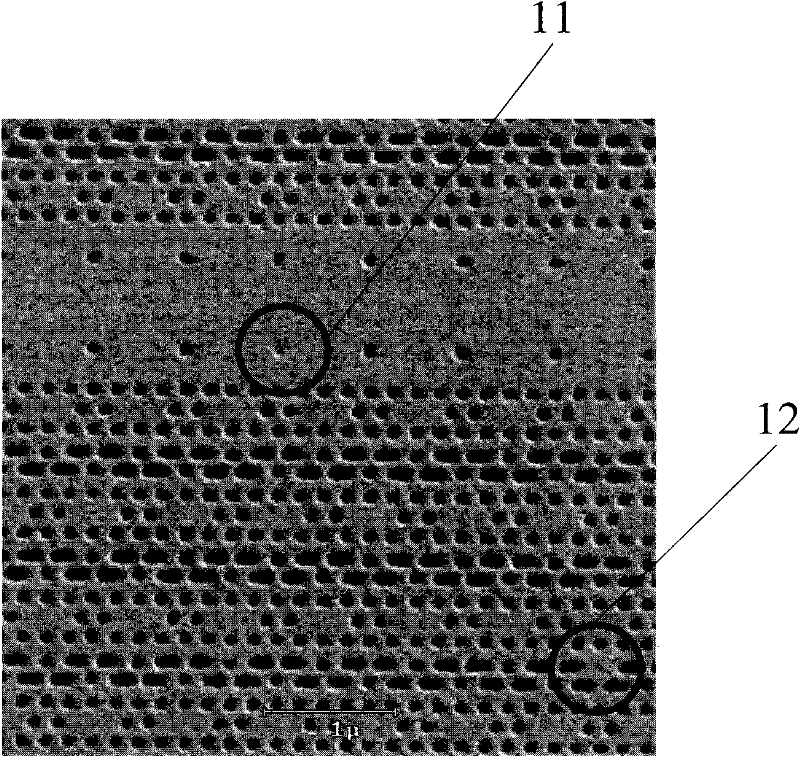

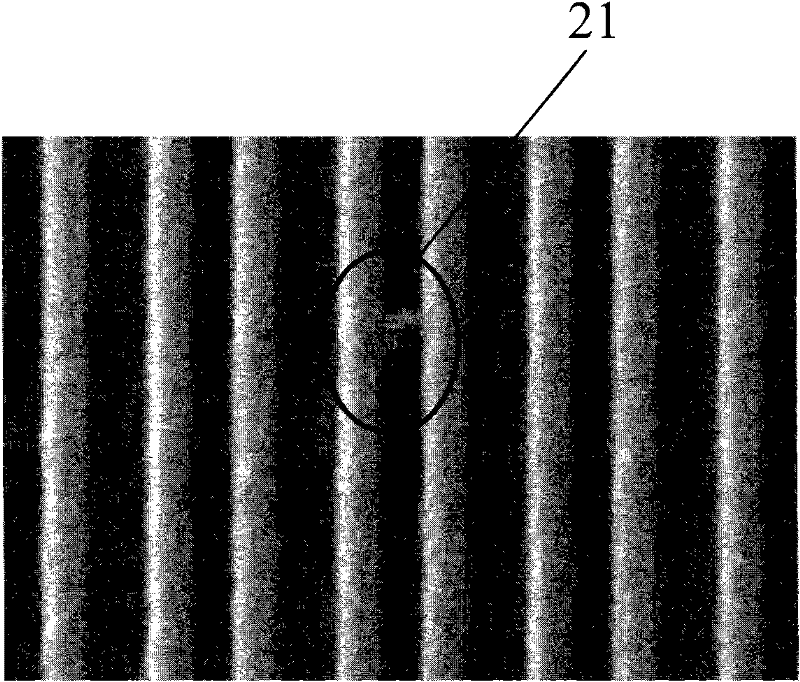

[0026] In the existing photolithography process, some impurities (such as metal ions) will inevitably be doped in the photoresist. With the miniaturization of the semiconductor manufacturing process, the metal ions will be mixed with the photoresist during the photolithography process. The polymer is easy to form a gel that is difficult to remove, which affects the effect of the photolithography process and reduces the yield of semiconductor products.

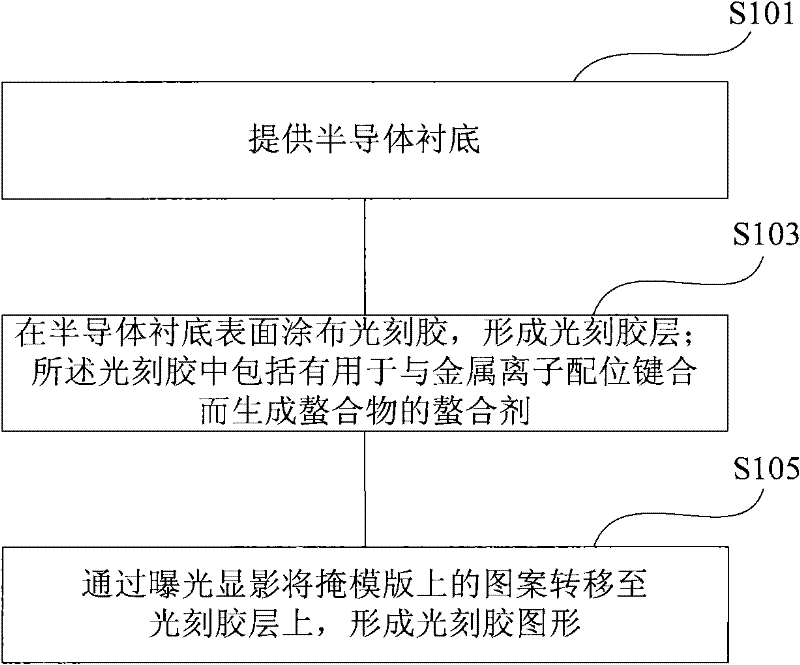

[0027] The invention improves the photoresist through experiments, and provides a new type of photoresist, which includes a chelating agent for coordination and bonding with metal ions to form a chelate. Preferably, the chelating agent is an ethylenediaminetetraacetic acid solvent, and the ethylenediaminetetraacetic acid solvent forms an ethylenediaminetetraacetic acid chelate in a ring structure with the metal ion.

[0028] In another aspect of the present invention, the photoresist containing the chelating agent is applied in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com