Power plant with co2 capture

A technology of power equipment and gas turbines, which is applied in the direction of mechanical equipment, machines/engines, steam engine devices, etc., and can solve problems such as performance, efficiency, and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

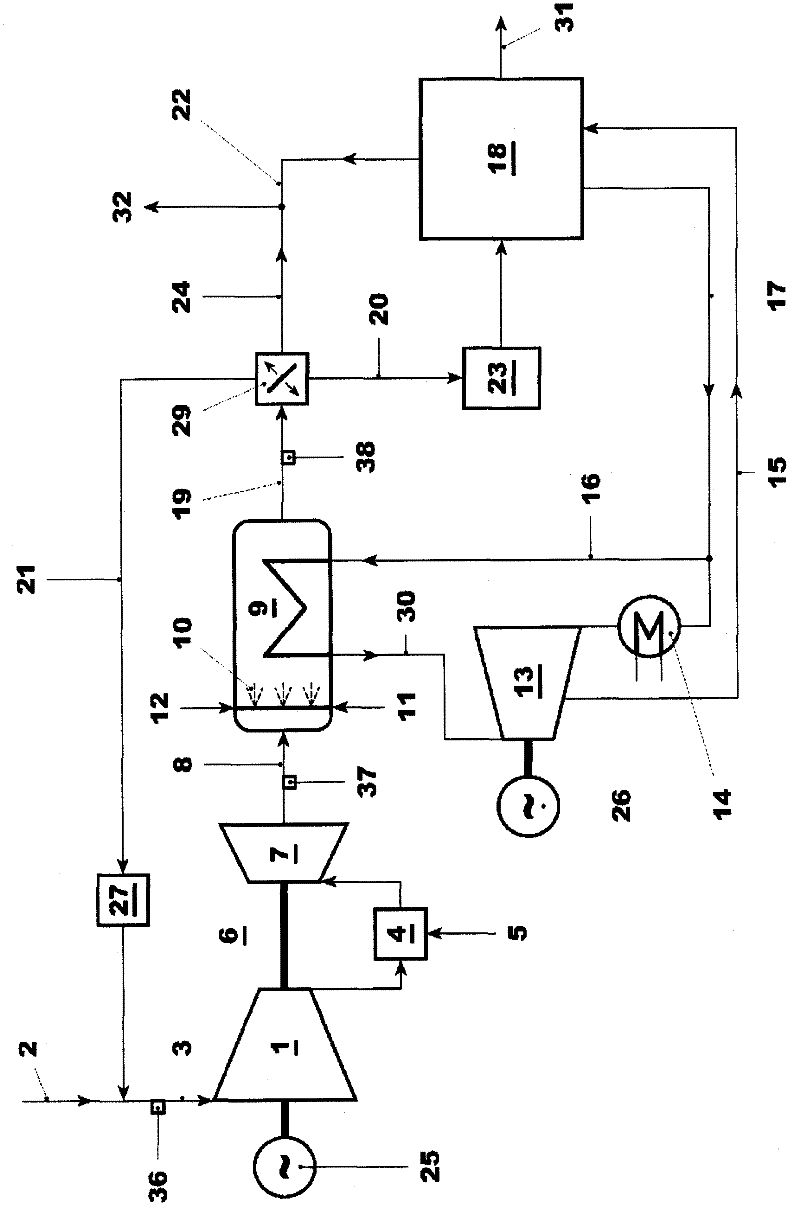

[0044] The power plant used to perform the proposed method includes a conventional CCPP, equipment for flue gas recirculation, afterburner 10, and CO 2 capture system 18 .

[0045] exist figure 1 A typical arrangement with post combustion capture, flue gas recirculation and afterburner 10 is shown in . Compressor inlet gas 3 and fuel 5 are supplied to a gas turbine 6 that drives a first generator 25 . The compressor inlet gas 3 is a mixture of ambient air 2 and a first partial stream 21 of flue gas which is recirculated through the flue gas recirculation line. Inlet gas is compressed in compressor 1 . The compressed gas is used in combustor 4 to burn fuel 5 and the pressurized hot gas is expanded in turbine 7 . Its main outputs are electrical power and hot flue gas8.

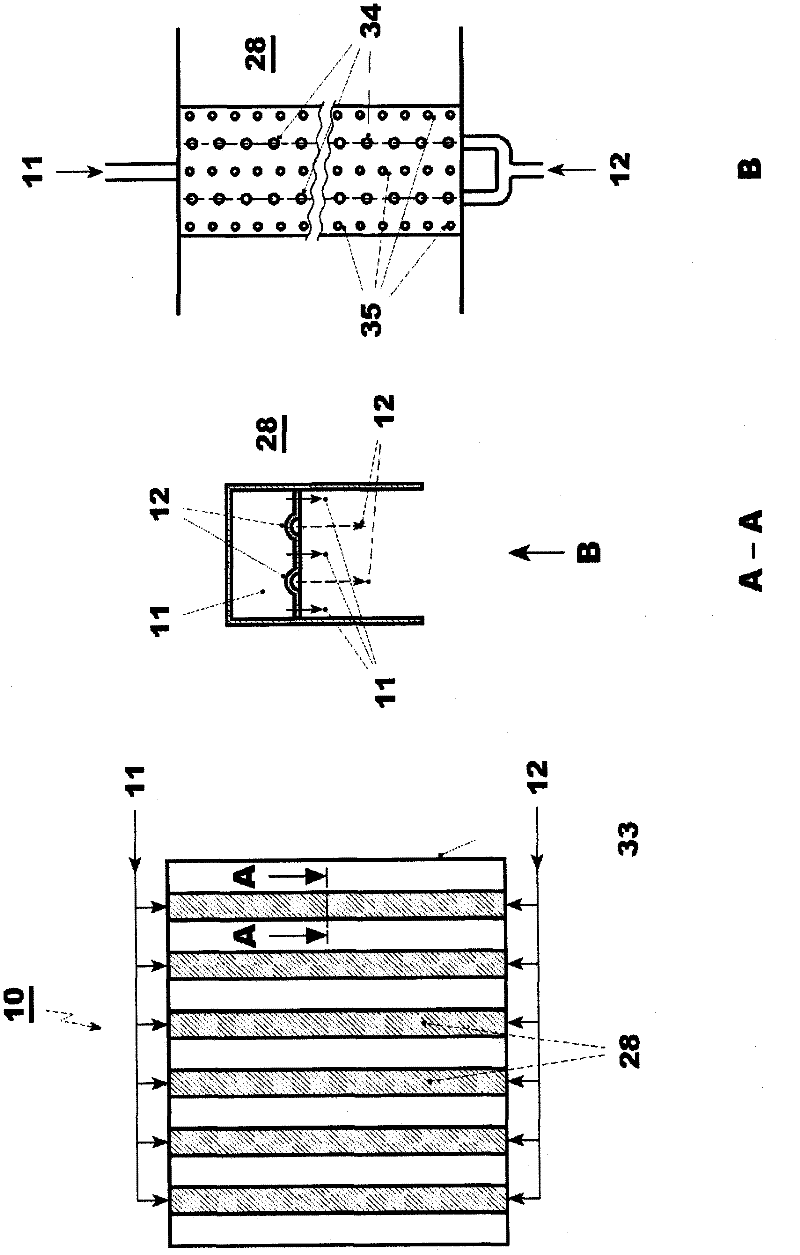

[0046] The hot flue gas 8 of the gas turbine passes through the HRSG 9 which produces steam 30 for the steam turbine 13 . An afterburner 10 is integrated in the HRSG 9 or in the flue gas duct from the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com