A kind of implementation process of seamless wall covering

A technology of seamless wall covering and craftsmanship, applied in the field of building decoration materials, can solve the problems of large material loss, easily damaged wallpaper, time-consuming and labor-intensive, etc., and achieve the effects of less material waste, high decoration grade and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

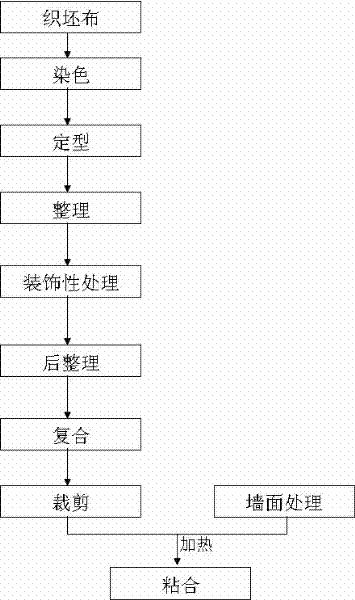

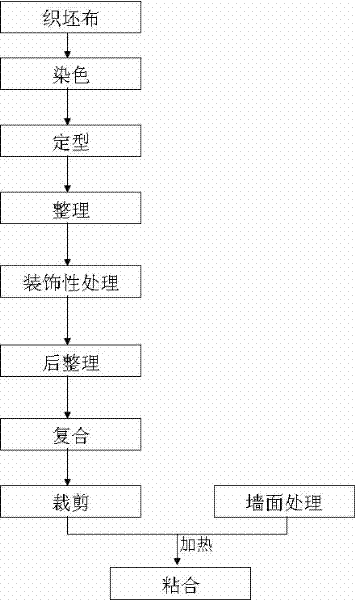

[0026] A kind of implementation technology of seamless wall cloth, it comprises following processing steps:

[0027] (1) Production of the base fabric: the gray fabric is produced on a wide-width textile machine, and the base fabric is obtained by dyeing, shaping, finishing, decorative treatment and post-finishing of the gray fabric. Wherein, the width of the base fabric is 2.7m~3.3m, which is specifically a kind of fiber fabric, and the width meets the requirements of the storey height of general houses. Therefore, there is no need to splicing patterns during use, and only needs to be cut according to the wall area. , to achieve true seamless pasting, and to make less material waste and lower cost. Further, the temperature during the setting is 180°C, thereby increasing the firmness of the color, so that the base fabric does not deform or fade; the post-finishing mainly performs waterproof, antifouling, and oil-proof treatment, and the specific process temperature is 160°C. ...

Embodiment 2

[0031] A kind of implementation technology of seamless wall cloth, it comprises following processing steps:

[0032] (1) Production of the base fabric: the gray fabric is produced on a wide-width textile machine, and the base fabric is obtained by dyeing, shaping, finishing, decorative treatment and post-finishing of the gray fabric. Wherein, the width of the base fabric is 2.7m~3.3m, which is specifically a kind of fiber fabric, and the width meets the requirements of the storey height of general houses. Therefore, there is no need to splicing patterns during use, and only needs to be cut according to the wall area. , to achieve true seamless pasting, and to make less material waste and lower cost. Further, the temperature during the setting is 150°C, which increases the firmness of the color and prevents the base fabric from being deformed or faded; the finishing is mainly carried out with waterproof, fireproof, and oil-proof treatment, and the specific process temperature i...

Embodiment 3

[0036] A kind of implementation technology of seamless wall cloth, it comprises following processing steps:

[0037] (1) Production of the base fabric: the gray fabric is produced on a wide-width textile machine, and the base fabric is obtained by dyeing, shaping, finishing, decorative treatment and post-finishing of the gray fabric. Wherein, the width of the base fabric is 2.7m~3.3m, which is specifically a kind of fiber fabric, and the width meets the requirements of the storey height of general houses. Therefore, there is no need to splicing patterns during use, and only needs to be cut according to the wall area. , to achieve true seamless pasting, and to make less material waste and lower cost. Further, the temperature during the setting is 250°C, which increases the firmness of the color and prevents the base fabric from being deformed or faded; the finishing is mainly carried out with waterproof, fireproof, and oil-proof treatment, and the specific process temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com