A rapid detection method for dimethylformamide residues in textiles

A technology of dimethylformamide and a detection method, which is applied in the field of rapid detection of dimethylformamide residues in textiles, can solve the problems of being susceptible to interference, taking a long time, and having false positives, and achieving an environment-friendly, The method is sensitive and easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

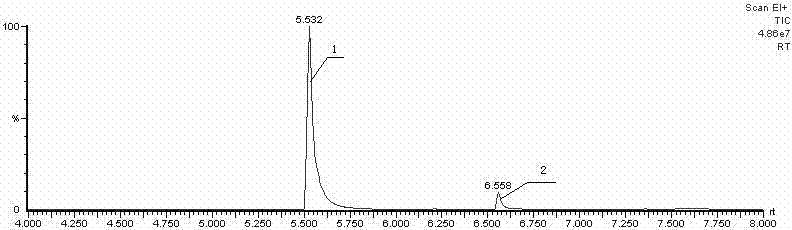

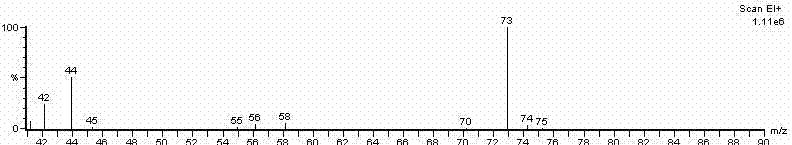

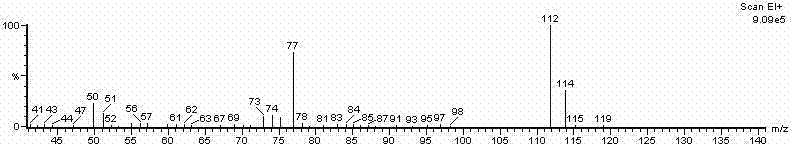

Image

Examples

Embodiment 1

[0030] DMF standard solution: add about 50mL of methanol in advance to a 100mL volumetric flask, and then add 50.0 mg of DMF to prepare a 0.5 mg / mL methanol solution.

[0031] Internal standard (chlorobenzene) standard solution: add about 50mL of methanol to a 100mL volumetric flask, then add 50.0 mg of chlorobenzene, then add methanol to the mark to prepare a 0.5 mg / mL methanol solution.

[0032] The samples were pretreated first, shredded and mixed. Accurately weigh 1.0 g of the sample to be tested and place it in a pre-dried headspace vial, add 2.0 μL of internal standard (chlorobenzene) standard solution, seal and mix well.

[0033] Sample pretreatment for adding standard samples: Accurately weigh 1.0 g of the sample to be tested and place it in a headspace vial, add 2.0 μL internal standard (chlorobenzene) standard solution, and add 2.0 μL DMF standard solution, seal and mix well.

[0034] The two samples were equilibrated in an oil bath at 40°C for 10 min, then inserted...

Embodiment 2

[0037] DMF standard solution: Accurately weigh 200.0 mg DMF into a 100 mL volumetric flask to prepare a 2.0 mg / mL methanol solution.

[0038] Internal standard (chlorobenzene) standard solution: Accurately weigh 200.0 mg of chlorobenzene into a 100 mL volumetric flask to prepare a 2.0 mg / mL internal standard solution of chlorobenzyl alcohol.

[0039] The samples were pretreated first, shredded and mixed. Accurately weigh 2.5 g of the sample to be tested and place it in a pre-dried headspace vial, add 2.0 μL of internal standard (chlorobenzene) standard solution, seal and mix well.

[0040] Sample pretreatment for adding standard samples: Accurately weigh 2.5 g of the sample to be tested and place in a headspace vial, add 2.0 μL internal standard (chlorobenzene) standard solution, and add 2.0 μL DMF standard solution, seal and mix well.

[0041] The two samples were equilibrated in an oil bath at 60°C for 5 min, then inserted into the solid-phase microextraction head, extracte...

Embodiment 3

[0044] DMF standard solution: Accurately weigh 500.0 mgDMF into a 100 mL volumetric flask to prepare a 5.0 mg / mL methanol solution.

[0045] Internal standard (chlorobenzene) standard solution: Accurately weigh 500.0 mg of chlorobenzene into a 100 mL volumetric flask to prepare a 5.0 mg / mL internal standard solution of chlorobenzyl alcohol.

[0046]The samples were pretreated first, shredded and mixed. Accurately weigh 5.0 g of the sample to be tested and place it in a pre-dried headspace vial, add 2.0 μL of internal standard (chlorobenzene) standard solution, seal and mix well.

[0047] Sample pretreatment for adding standard samples: Accurately weigh 5.0 g of the sample to be tested and place it in a headspace vial, add 2.0 μL internal standard (chlorobenzene) standard solution, and add 2.0 μL DMF standard solution, seal and mix well.

[0048] The two samples were equilibrated in an oil bath at 80°C for 3 min, then inserted into the solid-phase microextraction head, extract...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionization potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com