Preparation method for lipoic acid polymer impurities and detection method for lipoic acid polymer impurities

A technology of d-lipoic acid and its composition, which is applied in the field of preparation and detection of lipoic acid polymer impurities, can solve the problems of undetectable polymer impurities, adverse reactions, curative effect and safety hazards, etc., and achieves simple operation, Easy to obtain raw materials and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

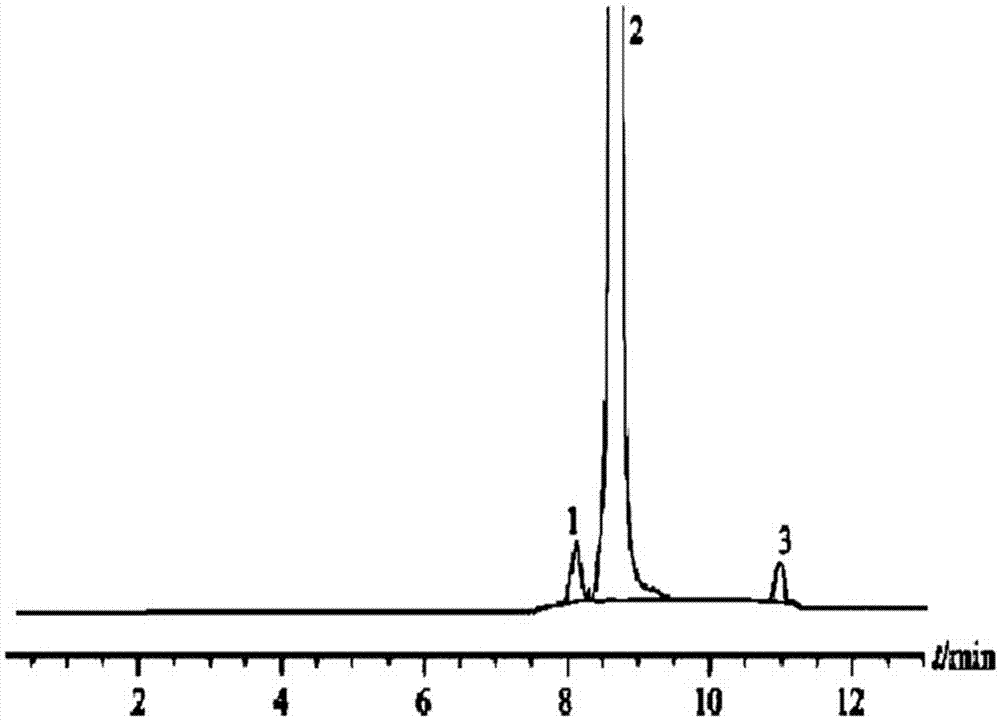

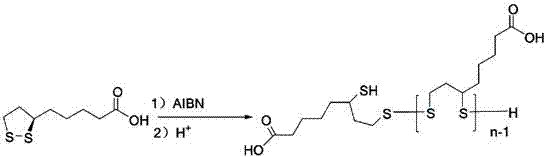

[0051] The preparation of embodiment 1 D-lipoic acid oligomer

[0052] Dissolve 10g of D-lipoic acid monomer in 200mL of anhydrous dioxane, add catalytic amount of azobisisobutyronitrile 0.5g, stir at 35-40°C for 15min, then rapidly cool down to 10-15°C In between, heat and stir for 1h, add about 10mL of 5% dilute hydrochloric acid to terminate the reaction; put the reaction solution into a mixture of 400mL ethyl acetate and 400mL water, stir and separate layers, take the ethyl acetate layer, and then use ethyl acetate Extract twice with 200mL, combine the organic layers, concentrate to a volume of about 50mL, add isopropyl ether 300mL, precipitate a light yellow semi-solid, filter, and vacuum dry at 30±2°C for 10h to obtain the above-mentioned d-lipoic acid oligomer The composition is about 7.5g, the yield is 75%, and the HPLC purity is 98.5%.

Embodiment 2

[0053] The refining of embodiment 2 D-lipoic acid oligomers

[0054] Suspend 5 g of the crude d-lipoic acid oligomer obtained in Example 1 in 40 mL of methyl isoamyl ketone, stir to disperse, raise the temperature to 45-50 °C, and slowly add ethanol / water with a volume ratio of 1:1 About 15mL of the mixed solvent is kept and stirred until it is completely dissolved, filtered while it is hot, slowly lowered to a temperature of 0-5°C, and the precipitated light yellow semi-solid is collected and vacuum-dried at 30±2°C for 12 hours to obtain 3.5g of a refined product with a purity of 99.5%.

Embodiment 3

[0055] Embodiment 3 Preparation of D-lipoic acid oligomer refined product

[0056] Dissolve 8g of D-lipoic acid monomer in 180mL of anhydrous tetrahydrofuran, add catalytic amount of azobisisobutyronitrile 0.4g, stir at 35-40°C for 20min, then quickly cool down to 10-15°C and keep warm Stir for 1 h, add 20 mL of 5% dilute phosphoric acid to terminate the reaction; put the reaction solution into a mixture of 400 mL of ethyl acetate and 400 mL of water, stir and separate layers, take the ethyl acetate layer, and extract the water layer twice with 200 mL of ethyl acetate, The organic layers were combined, concentrated to a volume of about 40 mL, and then 250 mL of isopropyl ether was added to precipitate a light yellow semi-solid, which was filtered and vacuum-dried at 30±2°C for 12 hours to obtain the composition of the above-mentioned d-lipoic acid oligomer of about 5.9 g, the yield is 78%, and the HPLC purity is 98.6%. The obtained product is further refined, that is, the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com