An organic electroluminescent device

An electroluminescent device, an organic technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of low luminous efficiency of blue materials and difficulty in meeting actual needs, and achieve the effect of increased brightness and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

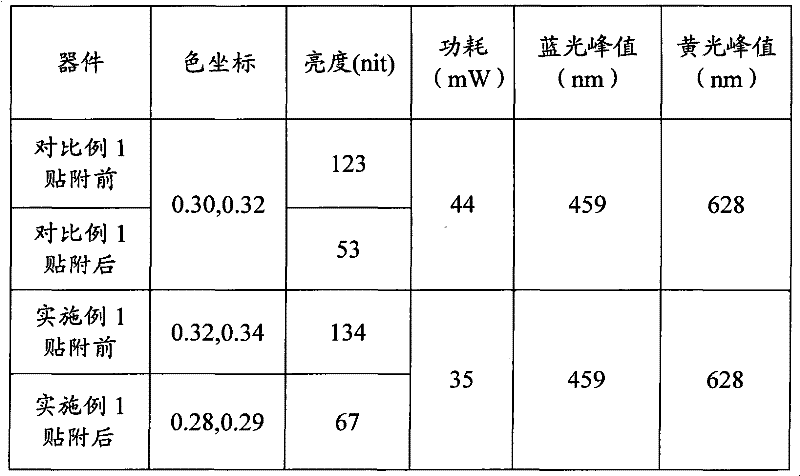

Embodiment 1

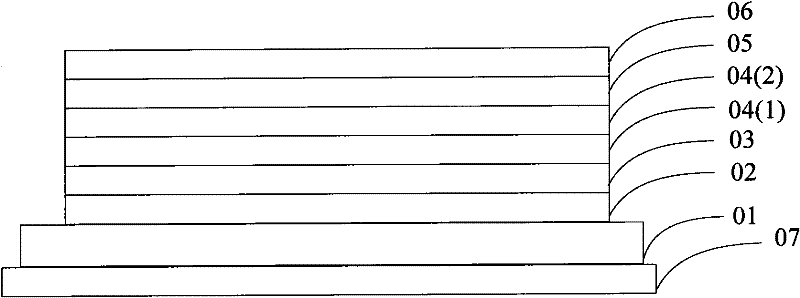

[0044] The device structure is:

[0045] ITO / HIL (850 ) / NPB(200 ) / BH:BD(90 , 4%) / RH:RD(300 , 2%) / Alq3(200 ) / LiF(5 ) / Al(1500 )

[0046] The process steps are:

[0047] (1) The glass substrate 01 is cleaned by ultrasound with boiling detergent and deionized water, and dried under an infrared lamp.

[0048] (2) Evaporate a layer of ITO on the glass as the anode 02, and the film thickness is 180nm;

[0049] (3) Evaporation of MTDATA (4,4',4"-tris(3-methylphenylaniline) triphenylamine) and F 4 TCNQ is used as HIL with a film thickness of 85nm. The mass percentage of F4TCNQ doped in MTDATA is 4%.

[0050] (4) Place the above-mentioned glass substrate with the anode in a vacuum chamber and evacuate to 1×10 -5 Pa, continue to vapor-deposit a layer of NPB film on the above-mentioned anode layer film as the hole transport layer 03, the rate is 0.1nm / s, and the vapor-deposited film thickness is 20nm;

[0051] (5) First use the method of double-source co-evaporation to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com