In-situ melting and reflow process and system for forming flip-chip interconnects

A melting temperature and displacement technology, applied in electrical components, circuits, manufacturing tools, etc., to solve problems such as increased electrical short circuits, poor reliability and quality of semiconductor packaging, and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

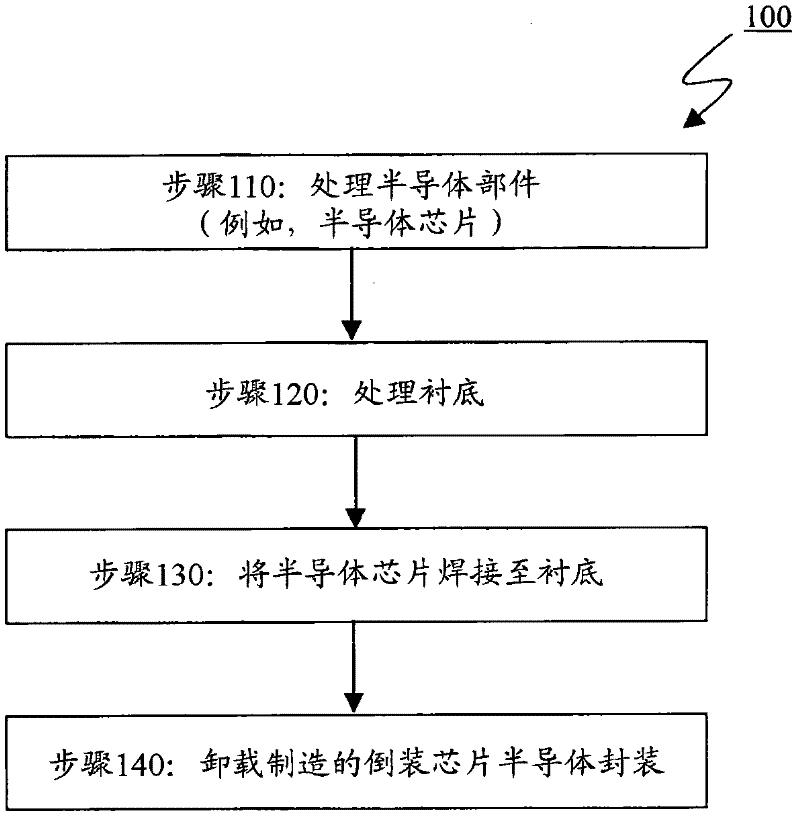

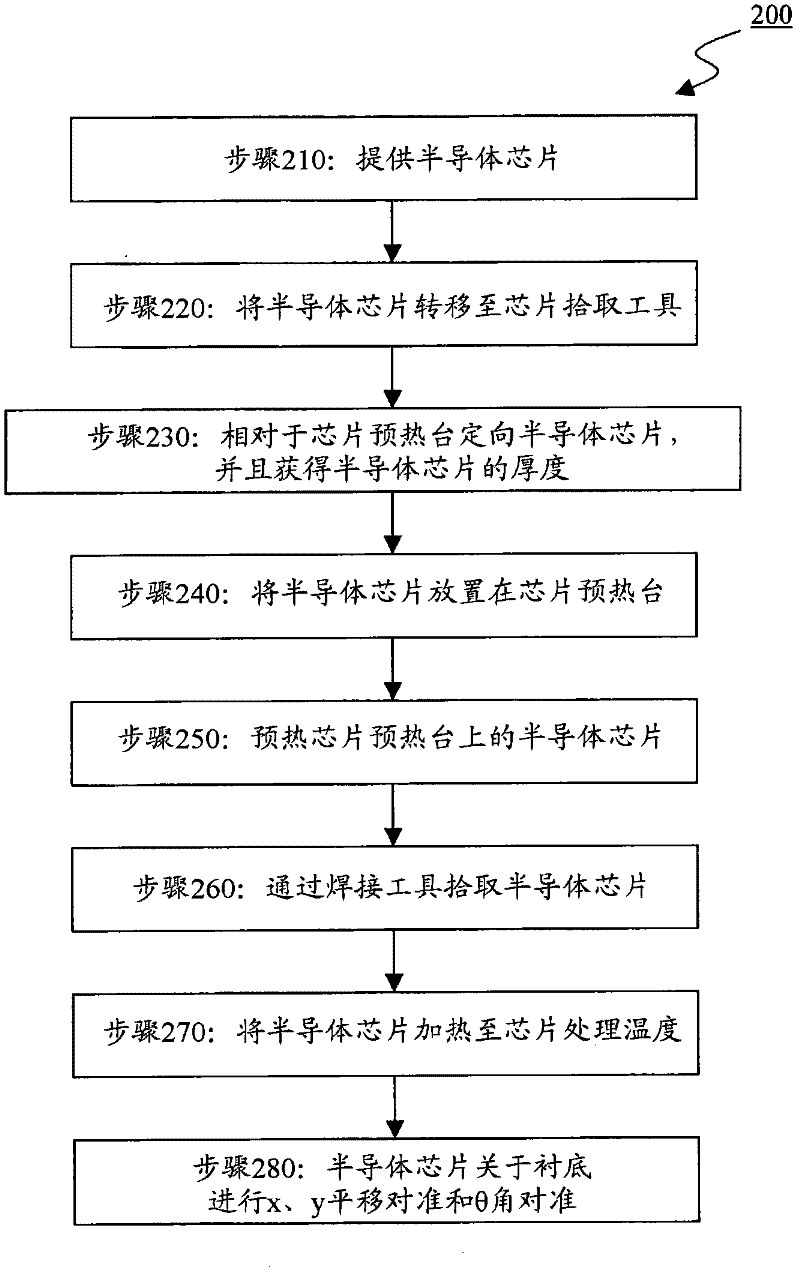

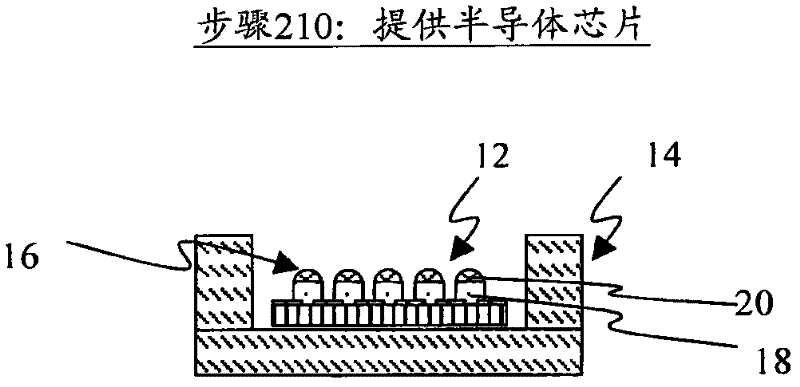

[0034] The current method of manufacturing flip-chip semiconductor packages is to heat the assembly of semiconductor chip and device carrier (eg, substrate) Solder bumps formed on pads or pillars of the semiconductor chip are placed on contact pads formed on the device carrier. This heating process is generally time-consuming, thereby adversely affecting the manufacturing or production efficiency and throughput of flip-chip semiconductor packages. Existing methods also generally involve the use of considerable force to bring the pads of the semiconductor chip into abutment with the contact pads of the device carrier, thereby producing reliable solder joints. Consequently, use of considerable force during its heating can cause damage to the semiconductor chip or device carrier. Furthermore, existing methods of manufacturing flip-chip semiconductor packages are associated with the problem of electrical shorts between adjacent interconnects formed between the semiconductor chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com