Aquaculture device and assembly and method thereof

An aquaculture and assembly technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of inability to provide a growing environment for aquatic seedlings, low survival rate of aquaculture organisms, etc., to avoid the growth of miscellaneous bacteria and reduce mortality. , to avoid the effect of mutual infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

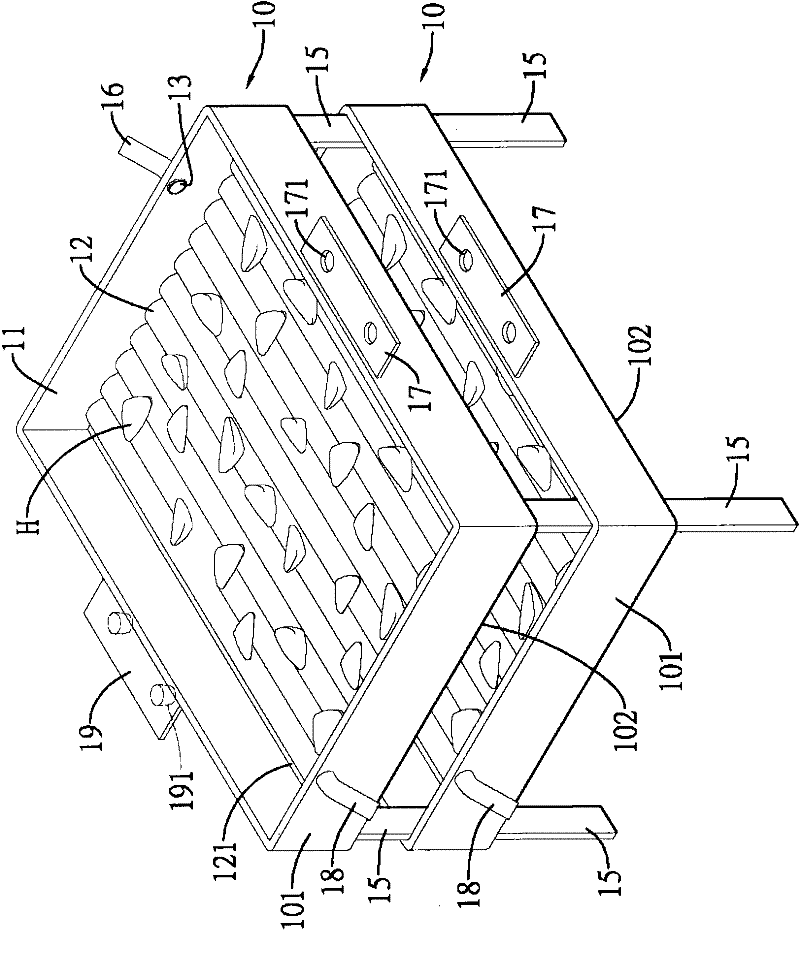

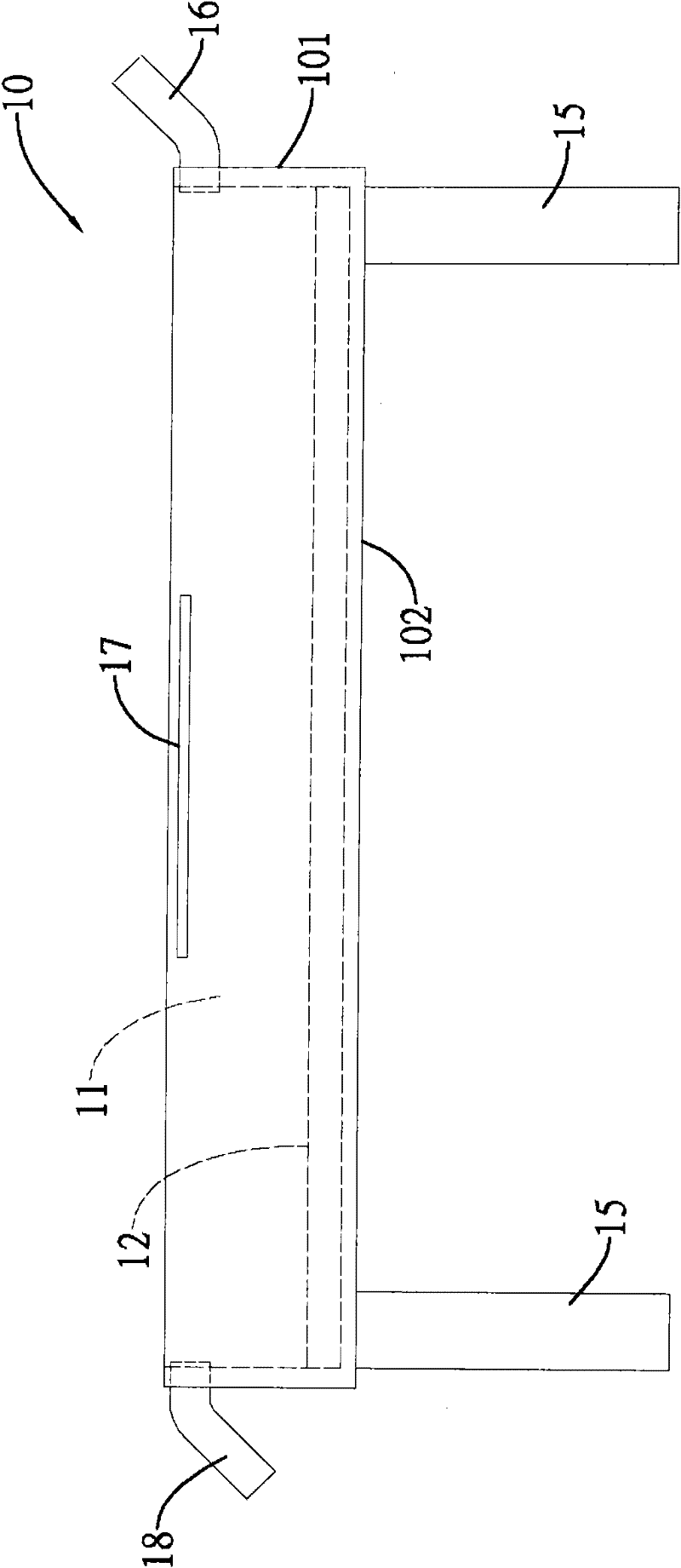

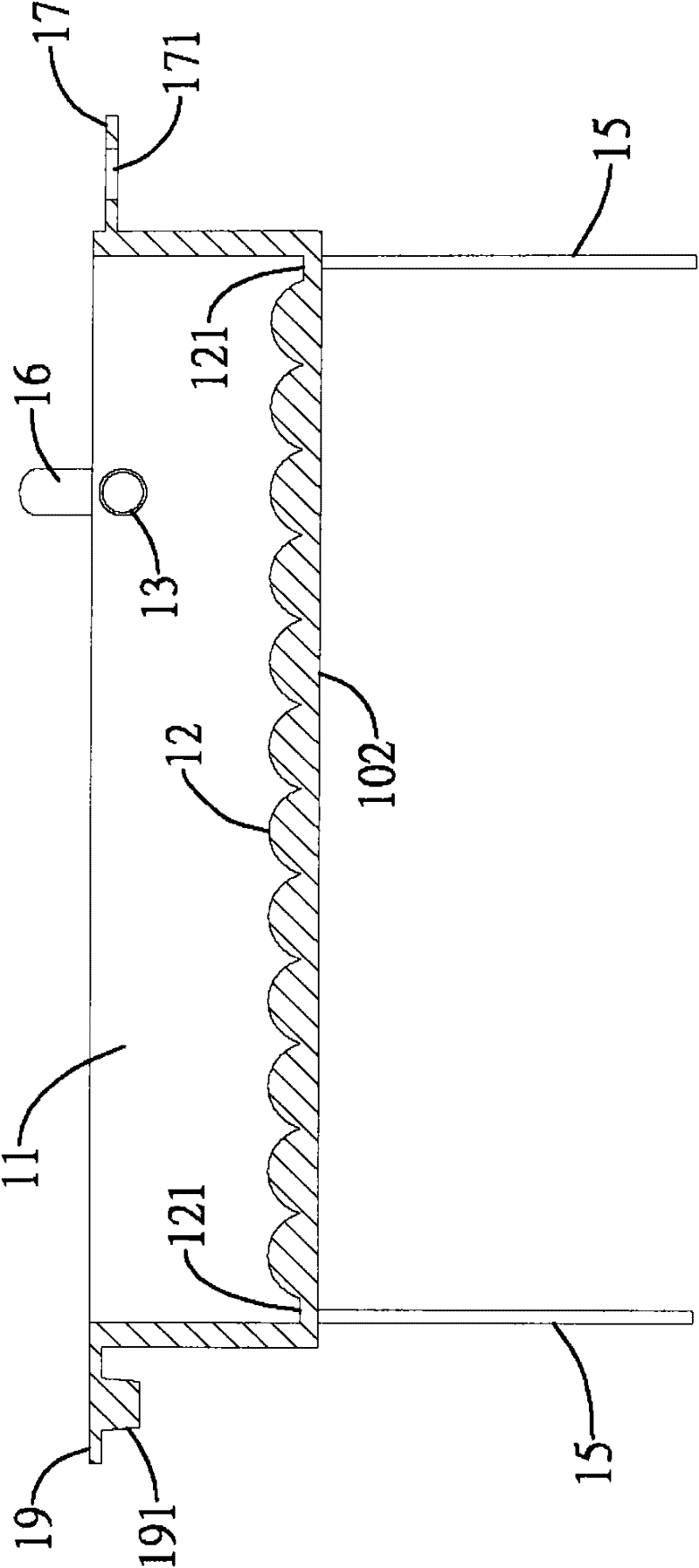

[0072] Example 1. Aquaculture device

[0073] A square seedling dish made of seawater corrosion-resistant material is made of metal in this embodiment, and the center of the top is depressed to form an aquaculture groove, and the bottom of the aquaculture groove It has a wavy structure. There are four tripods protruding from the bottom of the seedling tray. The side length of the seedling tray is 40 cm, and the height including the tripod is 15 cm. The opposite side walls of the seedling tray are respectively pierced with water inlets and drainage. The horizontal position of the water inlet or outlet is 5 cm higher than the bottom of the seedling tray, and 5 cm away from the closer edge of the side wall where it is located. The water pipe extends upwards from the water inlet at an angle of 15 degrees, and the drainage port is connected with a circular pipe-shaped drainage pipe, and the drainage pipe extends downwards from the drainage port at an angle of 15 degrees; the other ...

example 2

[0075] Example 2. Seawater treatment method

[0076] The seawater is pumped into the seawater purification pond, and treated with macroalgae for 2 days (the macroalgae can be asparagus (Gracilaria spp.) of Rhodophyta or Ulva spp. of Chlorophyta) .) etc. Processing capacity: 1 metric ton of seawater per 1 kg of wet weight seaweed every 2 days), and then filter the purified seawater with a filter with a pore size of 5 μm to remove suspended solids and other plankton, The treated seawater is stored in seawater storage tanks.

example 3

[0077] Example 3. Preparation of bait

[0078] Please see Figure 5 As shown, the diatoms (Navicula spp., Nitzschiaspp., Amphora spp., Cocconeis spp.), the initial concentration of diatoms is 5 ~ 7.5*10 4 cells / ml, placed in a 250ml Erlenmeyer flask for 7 days at 25°C, then transferred to a 2-liter Erlenmeyer flask for 7 days at 25°C, then transferred to a 20-liter PC plastic bucket at 25°C Cultivate for 7 days, and then switch to 500 liters of the bait supply tank of the aquaculture assembly of the present invention and cultivate for 7 days at room temperature (not specially adjusted to 25° C.), so that a large number of edible Abalone seedlings can be cultivated in the way of sequential amplification culture. Diatom (final concentration is 130~150*10 4 cells / ml). The culture media in Table 1 were used in the whole culture process of bait diatoms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com