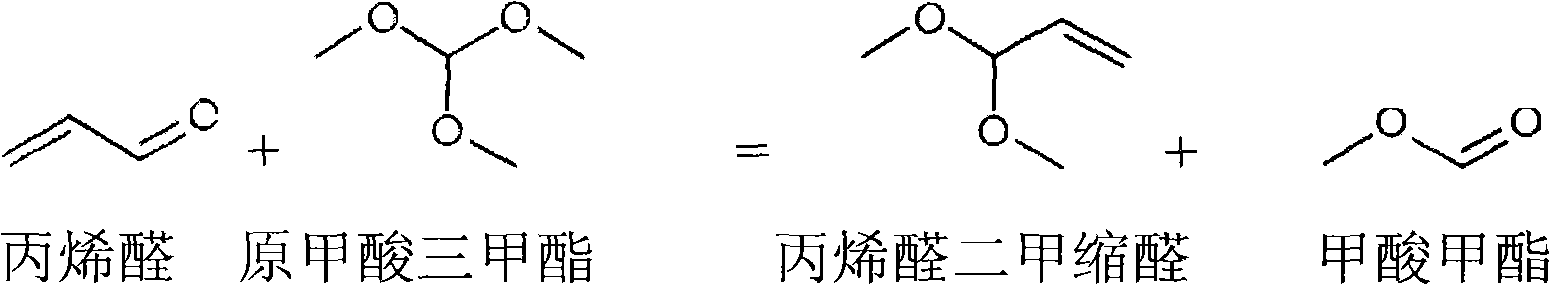

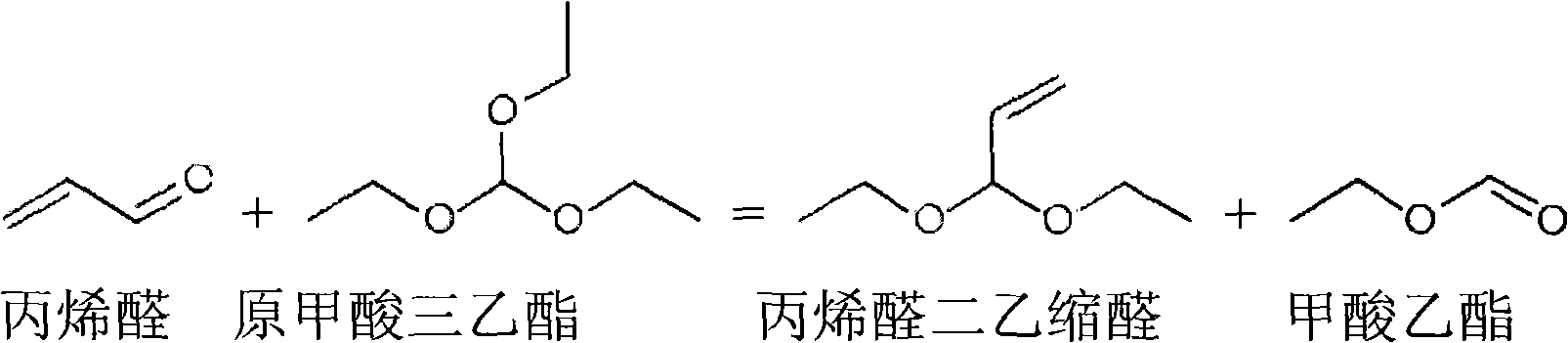

A method for preparing acetal with acrolein

A technology for acrolein and acetal, applied in the field of preparing acetal, can solve the problems of many side reactions, low acetal selectivity, difficult purification and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Put a 500ml three-neck flask equipped with a stirring device, a dropping funnel and a thermometer in a water bath, add 310g (2.09mol) of triethyl orthoformate, start stirring, slowly add 2.2g (0.0139mol) of benzenesulfonic acid, and pass through the water bath device Control the temperature at 30-40°C, add 112g (2.0mol) of acrolein dropwise at a constant speed, finish dropping within 1 hour, continue stirring for 2 hours, then add sodium carbonate, neutralize to PH7-7.5, stir for another 2 hours, and let stand for 4 hours , filter, remove insoluble solids, carry out normal pressure rectification operation, intercept 124-125 ℃ fraction 207g (GC detection, content 98.2%), namely acrolein diethyl acetal, yield 81.2%

[0025] Acrolein diethyl acetal GC detection method:

[0026] GC model: FULI 9790Ⅱ

[0027] Detection conditions: Nitrogen: 0.04MPa Hydrogen: 0.15MPa Air: 0.03MPa

[0028] Column temperature: 100-200°C Injection 200°C Detection 220°C

Embodiment 2

[0029] Embodiment 2: add and do not add the comparative test of solvent in the reaction:

[0030] Test A is with embodiment 1;

[0031] First add 100ml ethanol before test B reaction, other is with embodiment 1;

[0032] At first add 100ml ethyl acetate before test C reaction, other is with embodiment 1;

[0033] The yield and quality of acrolein diethyl acetal obtained after the reaction are shown in the table below:

[0034] Test No.

[0035] Conclusion: As can be seen from the above table, the reaction of the present invention without adding a solvent is better, and the yield and quality of acrolein diethyl acetal obtained after the reaction are better than those obtained with a solvent.

Embodiment 3

[0037] Put a 500ml three-neck flask equipped with a stirring device, a dropping funnel and a thermometer in a water bath, add 280g of trimethyl orthoformate (2.64mol), start stirring, slowly add 1.8g of sulfamic acid (0.019mol), and pass through the water bath device Control the temperature at 30-40°C, add 140g (2.54mol) of acrolein dropwise at a constant speed, finish dropping within 1 hour, continue stirring for 2 hours, then add sodium carbonate, neutralize to PH7-7.5, stir for another 2 hours, and let stand for 4 hours , filtered to remove the insoluble solids, then carry out normal pressure rectification operation, cut 201g of fraction at 89-91°C (GC detection, content 98.8%), which is acrolein dimethyl acetal, yield 81.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com