Preparation and application of a new type of resistant starch raw material

A resistant starch and starch technology, which is applied in food preparation, application, food science, etc., can solve the problems of unseen plantain taro, low added value of products, and no high content of resistant starch characteristics and advantages mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The preparation method of embodiment one canna taro resistant starch

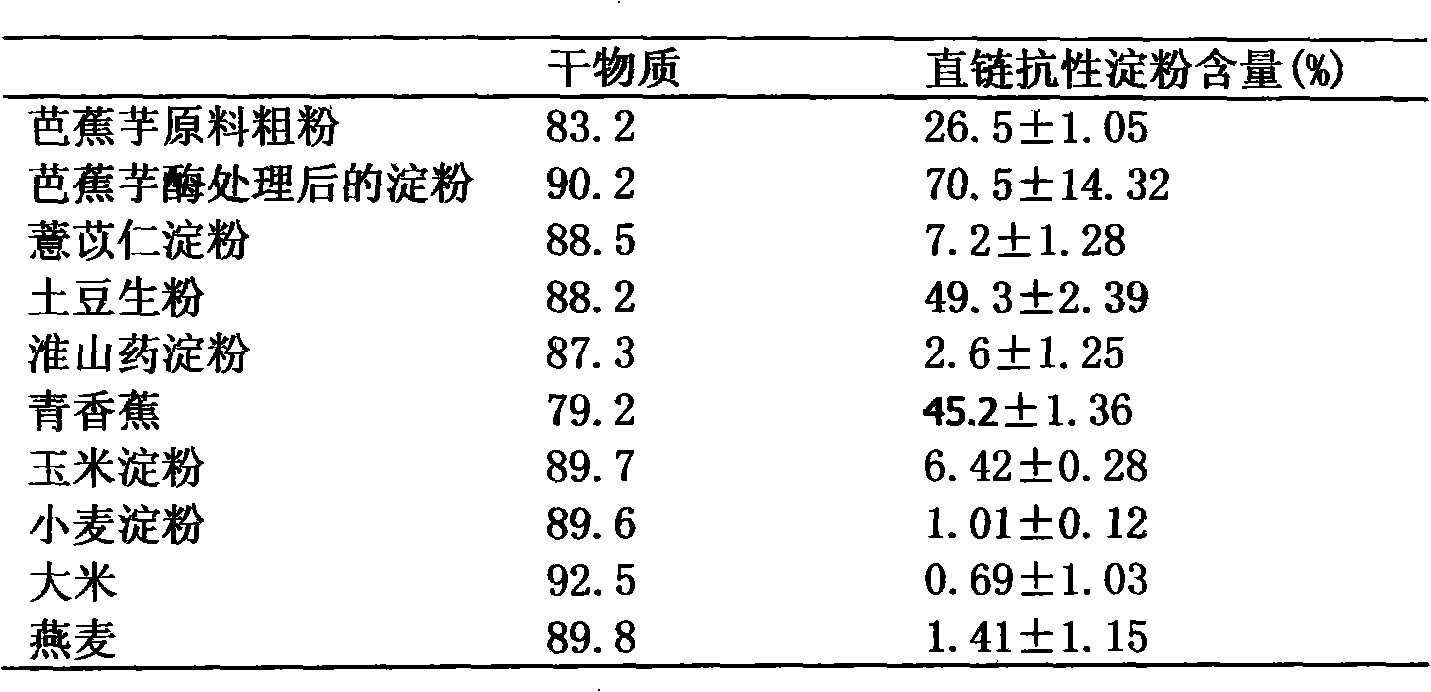

[0011] Wash and remove the mud from the fresh plantain taro, weigh, crush, filter and separate the fibers, repeat the starch sedimentation in cold water for 2-3 times, remove all impurities, and obtain coarse starch with a water content of 40%, and then sedimentation and separation with water for 2 -3 times, the plantain taro starch coarse powder was prepared, and the resistant starch content in the coarse powder reached 26%. Add water to adjust the slurry, the starch concentration of the slurry is between 10%-40%, add dilute hydrochloric acid or dilute sulfuric acid to adjust the pH3.5-5.5, heat with microwave or steam (stirring is required for steam heating), at 40-70°C Add pullulanase at low temperature, the dosage is 10-50 ASPU / g starch, keep warm for 6-48hrs, then raise the temperature to 80-100°C, keep it for 40-60min, cool down, after the starch precipitates, drain the liquid. In order to rem...

Embodiment 2

[0012] The determination of the content of embodiment secondary resistant starch

[0013] Weigh 100mg of sample into a 15mL centrifuge tube, add 10mL of KCI-HCI solution (pH 1.5), add 0.2mL of pepsin solution (1g pepsin / 10mL of KCl-HCI solution), keep the temperature at 38°C for 60min, and keep shaking continuously to remove the sample the protein in it; take it out, cool it naturally to room temperature, adjust the pH to 6.0-6.4, add 300U of heat-resistant α-amylase, place it in a constant temperature oscillator at 95°C for 30 minutes (oscillation speed is 200r / min), and hydrolyze the protein in it. Digestible starch, centrifuge (3000r / min, 10-15min); cool to room temperature, adjust the pH value to 4.5 with sodium acetate buffer, then add 5000 activity units of glucoamylase (60°C water bath shake for 60min), completely hydrolyze the starch Digestible starch is glucose; cool, centrifuge, (3000r / min, 15min), carefully discard the supernatant, wash with water, repeat 3 times, w...

Embodiment 3

[0026] The preparation of embodiment three canna taro resistant starch food (following example illustrates the present invention, but does not limit the present invention)

[0027] (1) Biscuits:

[0028] Take the preparation of 12kg biscuits as an example: 6kg of banana taro resistant starch, 4kg of wheat low refined starch, 70g of phospholipids, 1.5kg of xylitol, 20g of refined salt, 40g of baking soda, 30g of ammonium bicarbonate, 0.1g of citric acid, and others according to taste Add 1.0kg of cocoa powder, or 8ml of edible essential oils of other flavors. According to the conventional biscuit preparation process, the biscuit is prepared through modulation-rolling-forming-baking-cooling-packaging. The content of resistant starch is between 12% and 20%.

[0029] (2) Instant noodles

[0030] 1 part of canna resistant starch, 1 part of early indica rice, soak the early indica rice, wash and refine the rice, add the resistant starch of canna taro, add water to adjust the slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com