Gasoline engine tail gas treatment device with hydrocarbon catching function

A technology of exhaust gas treatment and hydrocarbon trap, which is applied in the direction of electronic control of exhaust gas treatment device, exhaust gas treatment and exhaust device, etc. The effect of reducing hydrocarbon emissions, reducing hydrocarbon emissions, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

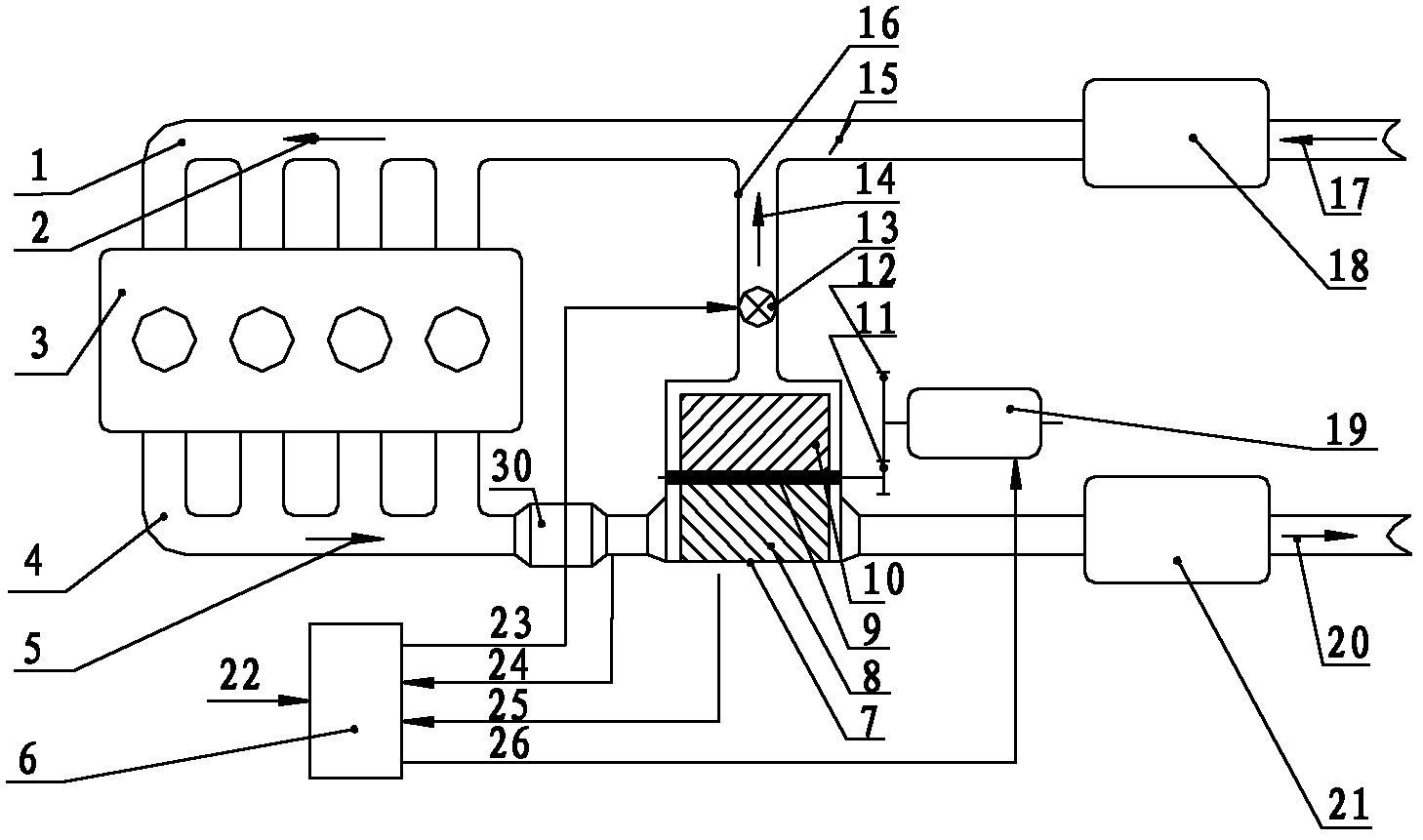

[0013] Below in conjunction with accompanying drawing, the present invention will be further described.

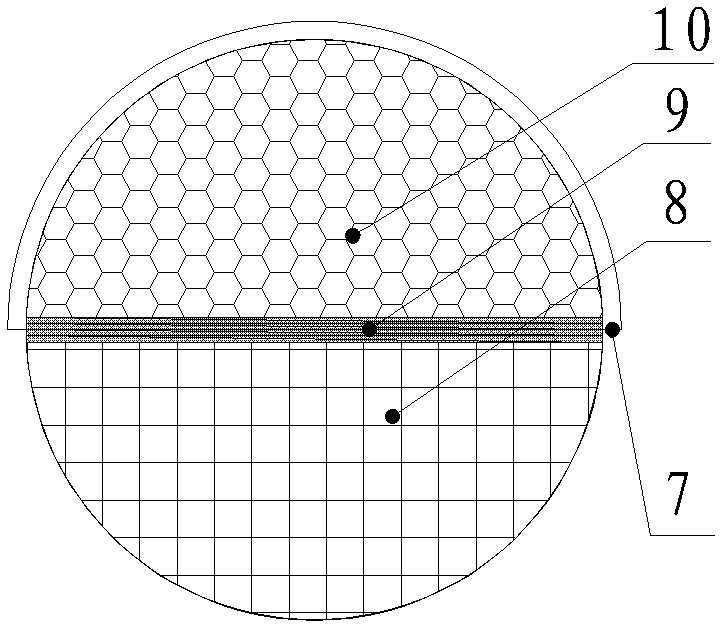

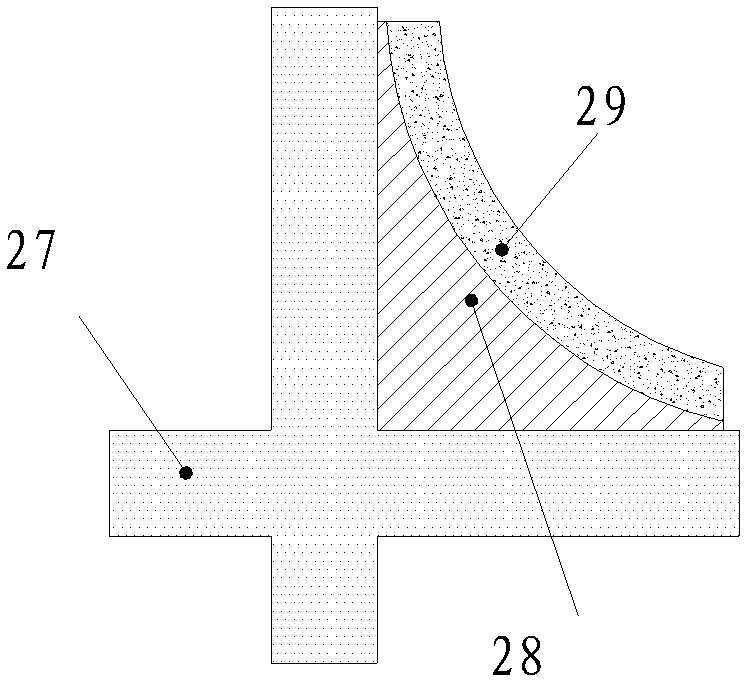

[0014] Such as figure 1 As shown, the semicircular hydrocarbon trap 8 and the semicircular three-way catalytic converter 10 are installed on a rotatable partition 9, and both are realized under the control of the electronic control unit 6 and the drive of the motor 19. any switch. During cold start and warm up, the electronic control unit 6 sends out the motor control signal 26 through the cold start judgment signal 22 and the partition position signal 25, adjusts the semicircular hydrocarbon trap 8 to the working position, and starts to collect exhaust gas Hydrocarbons in the medium, and at the same time heat the semicircular three-way catalytic converter 10 on the other side of the partition 9 through heat conduction. When the catalyst on the three-way catalytic converter 10 is ignited, the electronic control unit 6 controls the rotation of the motor 19 through signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com