Method for bonding carbon fiber pipe with metal flanges internally and externally

A technology of carbon fiber and metal, which is applied in the field of internal and external bonding of carbon fiber pipe fittings and metal flanges, can solve the problems of limiting the bearing capacity of carbon fiber pipe fittings, achieve the effect of increasing safety and reliability, improving overall bearing capacity, and improving connection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] The present invention proposes a method for internally and externally bonding a carbon fiber pipe fitting and a metal flange, which specifically includes the following steps:

[0027] Step 1: Surface treatment of carbon fiber pipe fittings and metal flanges to be connected:

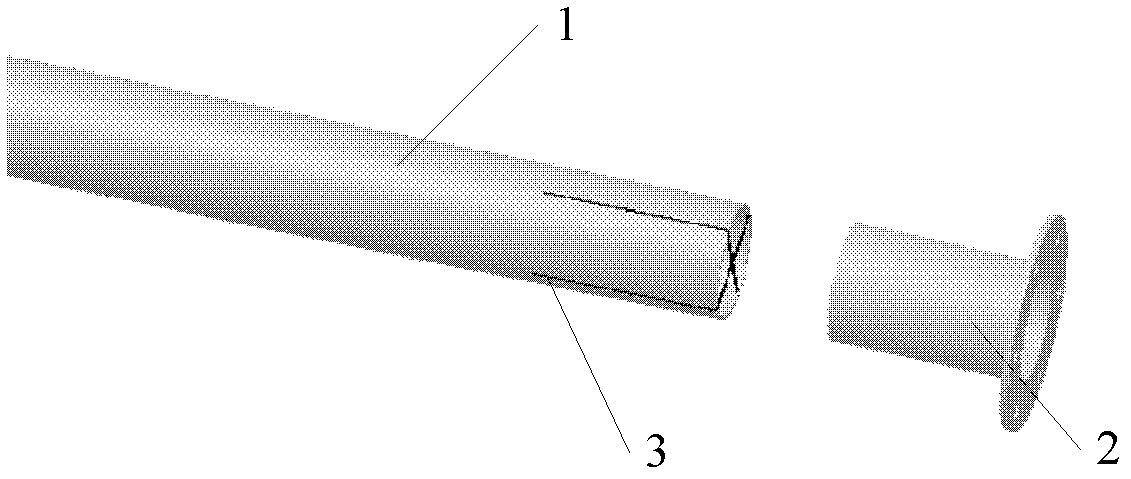

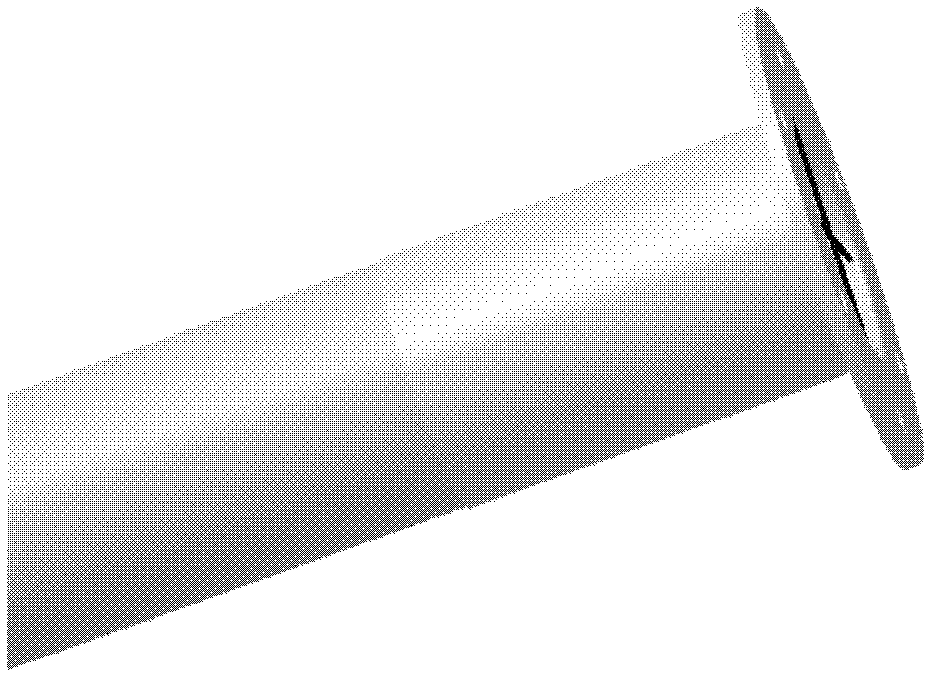

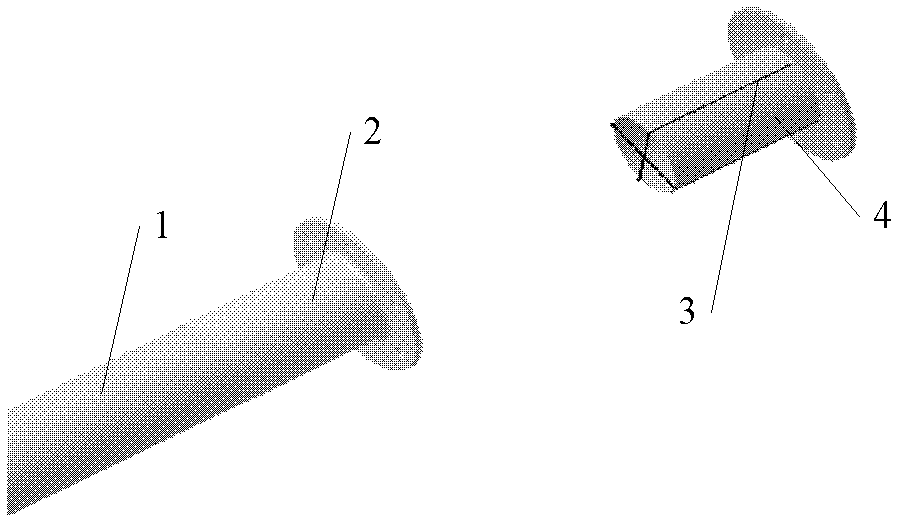

[0028] Such as figure 1 As shown, the inner and outer surfaces of the end of the carbon fiber pipe fitting 1 are evenly polished with sandpaper, and the sanding is stopped until carbon fiber black powder appears, and then the end of the carbon fiber pipe fitting 1 is cleaned with a dust-removing paper containing analytical pure alcohol, and the carbon fiber pipe fitting 1 is dried after cleaning , placed in an oven and baked at 60-70°C for 15-20 minutes; metal flanges (including metal inner flange 4 and metal outer flange 2) were anoded with phosphoric acid according to the aviat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com