A method and device for measuring span distance of cylindrical spur involute spline ring gauge

A technology of involute spline and measuring method, applied in the direction of ring gauge, measuring gauge, mechanical gap measurement, etc., can solve the problems of large loss, low efficiency, can not fully reflect the actual situation of the gauge, etc., to achieve improved efficiency and measurement results. Precise, faster effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

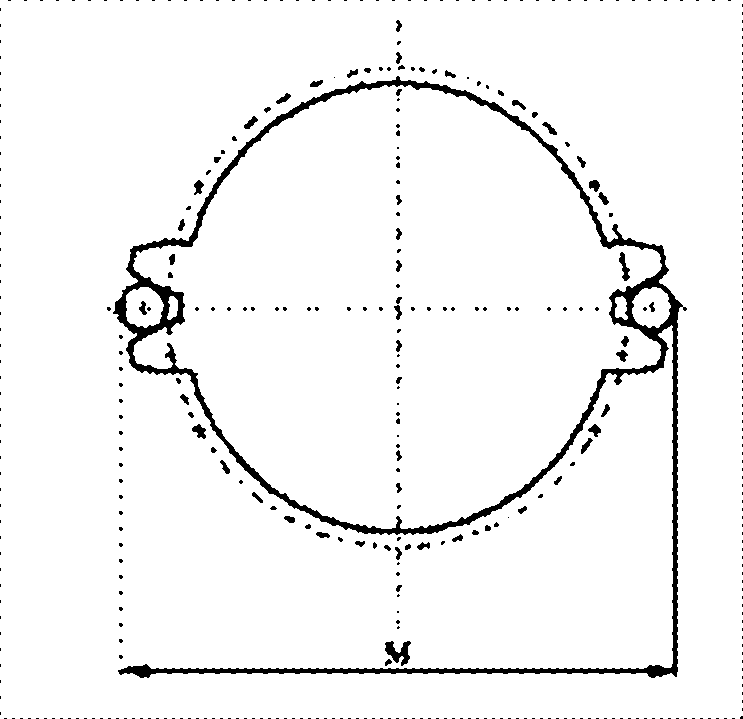

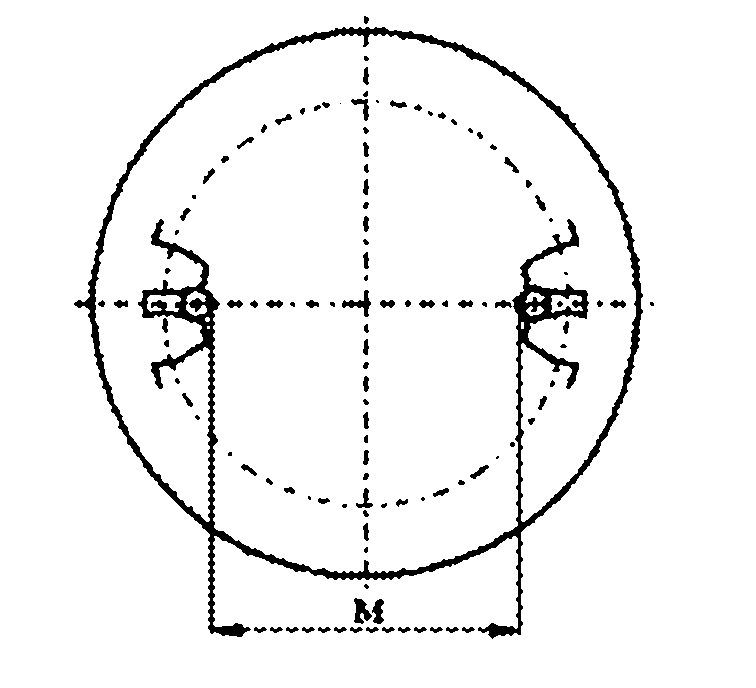

[0031] The present invention aims to provide a method and a measuring device suitable for measuring the M value of a cylindrical spur (even number) involute spline ring gauge to solve the problem of measuring the M value of a cylindrical spur (even number) involute spline ring gauge.

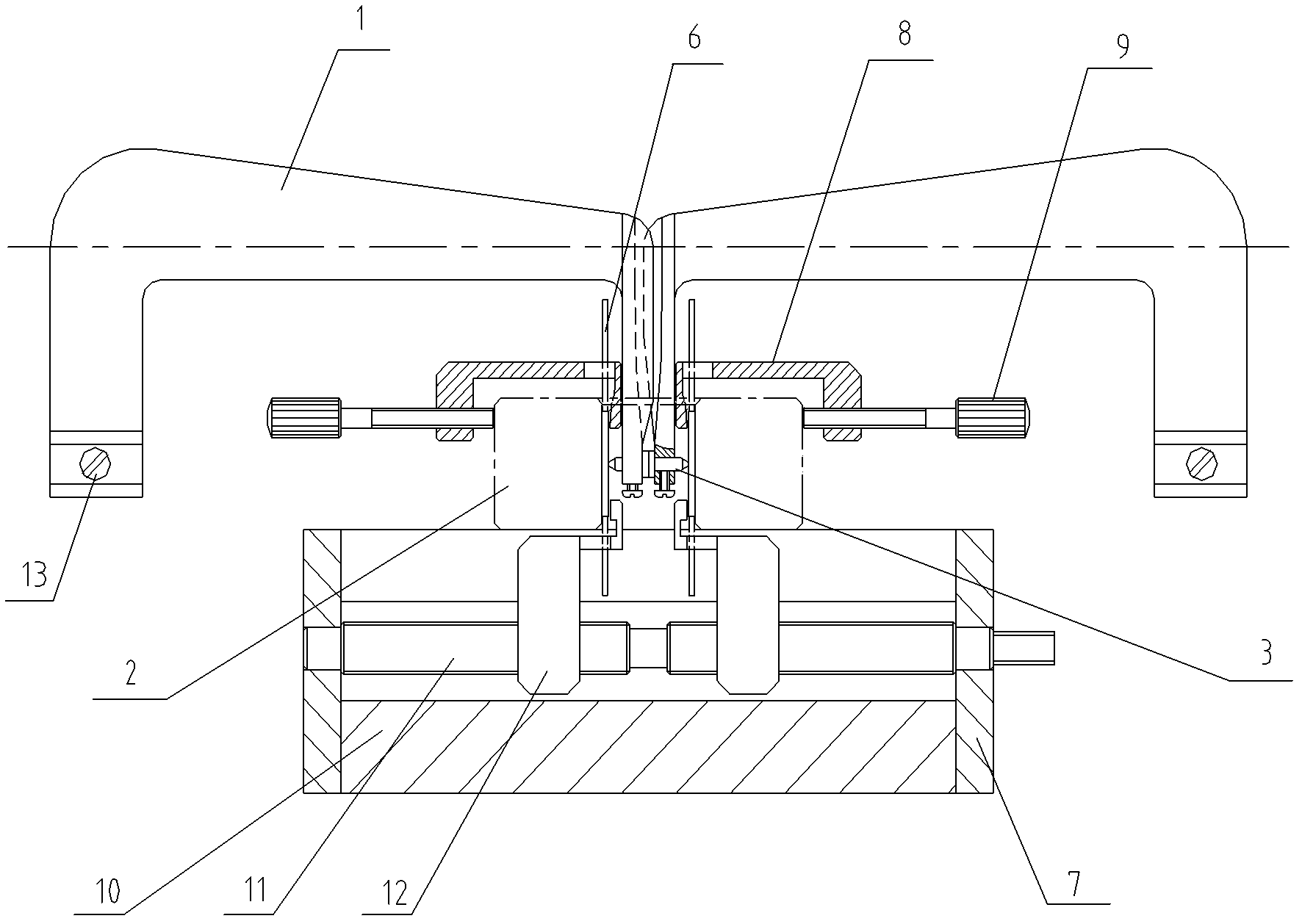

[0032] According to GB / T 5106-2006 cylindrical spur tooth involute spline gauge standard, the measurement method of cylindrical spur tooth involute spline ring gauge M value is studied. On the basis of the existing high-precision horizontal length measuring instrument, Develop a new type of measuring hook 1 and measuring probe 2 for internal dimension measurement, and adopt a new method of internal measuring probe calibration (by measuring the parallelism of the outer plane end to achieve the parallelism of the inner measuring hook and measuring probe measuring edge s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com