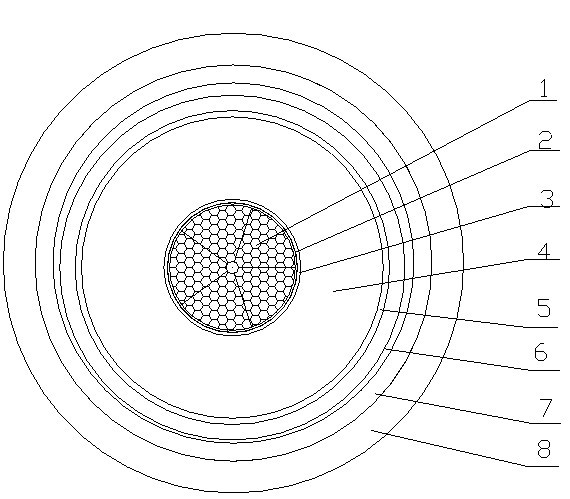

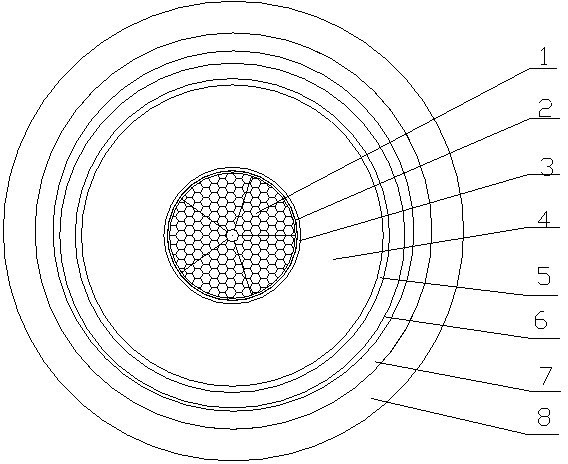

XLPE insulated power cable with split conductor structure

A technology of cross-linked polyethylene and segmented conductors, which is applied to power cables with shielding layers/conductive layers, conductors, non-insulated conductors, etc., and can solve the serious skin effect, skin effect, lack of economic practicability and Effectiveness and other issues to achieve the effect of increasing the current carrying capacity, reducing the influence of the skin effect, and reducing the increase in the AC resistance of the conductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Such as figure 1 As shown, the present invention mainly comprises the conductor 1 that is positioned at the cable center, and this conductor 1 forms the conductor that a whole cross-section is circular after being cabled by several fan-shaped strands, separates with insulating crepe paper between each strand, makes The strands are insulated from each other, so that the conductor is equivalent to being composed of several mutually insulated fan-shaped strands connected in parallel. Since the cross-sectional area of a single strand is only a fraction of the total cross-sectional area of the conductor, the "skin effect" and "proximity effect" of a single strand are greatly reduced, thereby achieving the purpose of reducing the AC resistance of the conductor. A semi-conductive wrapping tape 2, a semi-conductive shielding layer 3, an insulating layer 4, an insulating shielding layer 5, a semi-conductive buffer water-blocking tape 6, a corrugated aluminum sheath 7 and a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com