Large-capacity dry-type high-frequency high-voltage transformer

A high-frequency, high-voltage, transformer technology, used in fixed transformers or mutual inductance, transformer/inductor cooling, transformer/inductor cores, etc., to solve problems such as long-term reliability, small transfer capacity, and low boost voltage. , to achieve the effect of ensuring high-frequency insulation level, excellent dielectric properties, and high voltage output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

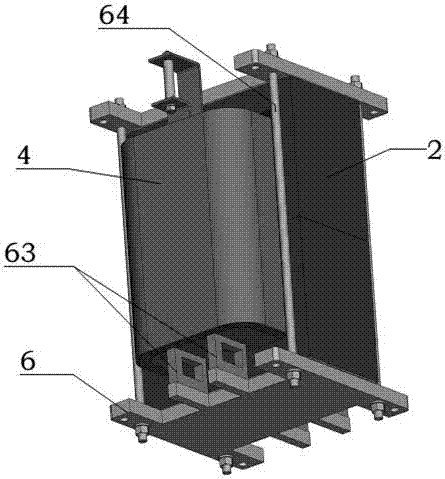

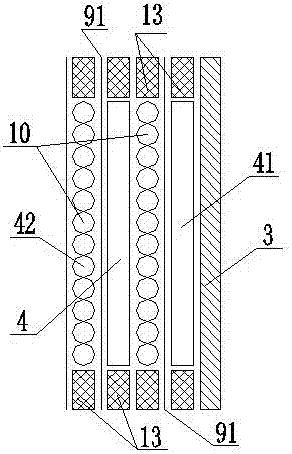

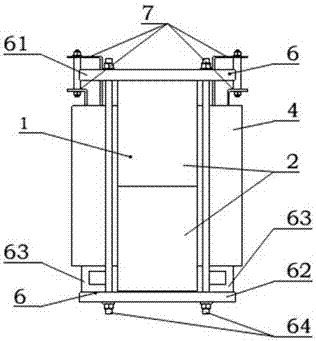

[0072] as attached Figure 1-13 As shown, the large-capacity dry-type high-frequency high-voltage transformer 1 of the present invention includes: an EE-type magnetic core 2, a square frame 3, a square coil 4, a fixed support device 6, and a copper bar or copper wire 7 for the coil. As shown in Figure 5, the EE-shaped magnetic core 2 is formed by two E-shaped magnetic cores 21 facing each other with openings aligned up and down. A closed magnetic circuit is formed between the upper and lower bottom yokes 22 , the middle column 23 and the side columns 24 of the EE-type magnetic core.

[0073] The square frame 3 is set on the center column 24 of the EE-type magnetic core 2, the square coil 4 is a vertical structure, and is wound on the square frame 3 by a combination of a low voltage coil 41 and a high voltage coil 42. The square coil 4 Axial heat dissipation air passage 5 is set in the heat dissipation air passage 5, and air passage stay 8 is arranged in the heat dissipation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com